Tin electroplating bath, tin-plated coating film, tin electroplating method, and electronic device component

一种锡电、锡盐的技术,应用在电子器件元件领域,能够解决可焊性降低等问题,达到容易控制、高可加工性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

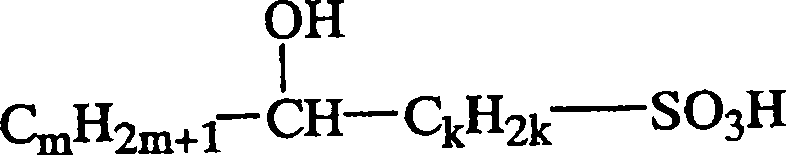

Method used

Image

Examples

Embodiment 1-24 and comparative example 1-12

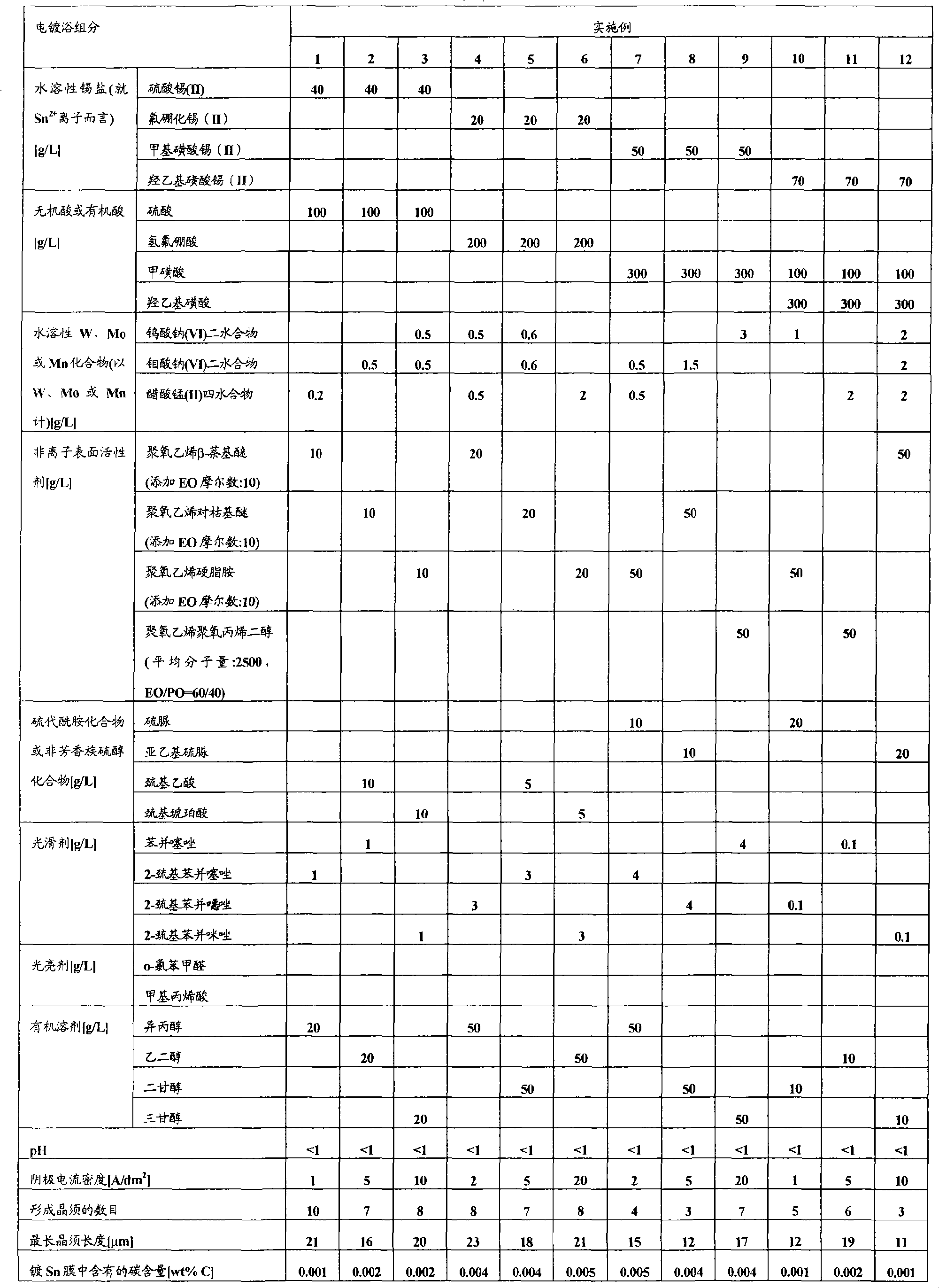

[0083] Tin electroplating baths of the compositions shown in Tables 1-3 were prepared. In each electroplating bath, lead frames of phosphor bronze (C5191 ), which had been pretreated in the usual manner, were dipped. Use the lead frame as the cathode and the tin plate as the anode respectively, and perform tin electroplating at a bath temperature of 45°C and the cathode current density shown in Table 1-3 to form a 2-3 μm thick tin plating film.

[0084] Then, after the lead frame with the tin-plated film formed thereon was placed under constant temperature and humidity conditions of 30° C. and 60% RH for 1 week, the surface of the tin-plated film on the lead frame was microscopically observed through a scanning electron microscope, and each Unit area (0.51mm×0.42mm≈0.21mm 2 ) on the number of 10 μm or longer whiskers. In addition, the longest whisker length is also detected. The reason for counting only whiskers of 10 μm and longer is based on the definition of whiskers giv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com