Whisker reinforced aluminum oxide composite ceramic as well as preparation method and application thereof

A composite ceramic and alumina technology, applied in the field of ceramic materials, can solve the problems of affecting the mechanical properties of wear resistance, the growth of alumina grains, and the high cost, and achieve the effects of improving toughness, reducing sintering temperature, and improving wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Al 2 o 3 -SiC whiskers

[0041] (1) Mixing: 75 grams of Al 2 o 3 25 grams of SiC whiskers (diameter 0.5um, aspect ratio 10-30) were added to absolute ethanol to make a mixed powder, and ultrasonically dispersed for 10 minutes; then put into grinding balls, the ball-to-material ratio was 1:1 , ball milled for 10 hours to obtain a slurry;

[0042] (2) Drying: put the ball-milled slurry into a rotary evaporator and dry at 60°C; after the powder is dried, pass through a 60-mesh sieve to obtain a mixed powder;

[0043] (3) Forming: the sieved mixed powder is formed by dry pressing with a steel mold with a diameter of 50 mm, and the pressure is 30 MPa to obtain a block of a corresponding shape, and then cold isostatic pressing is performed at a pressure of 200 MPa to obtain a green body;

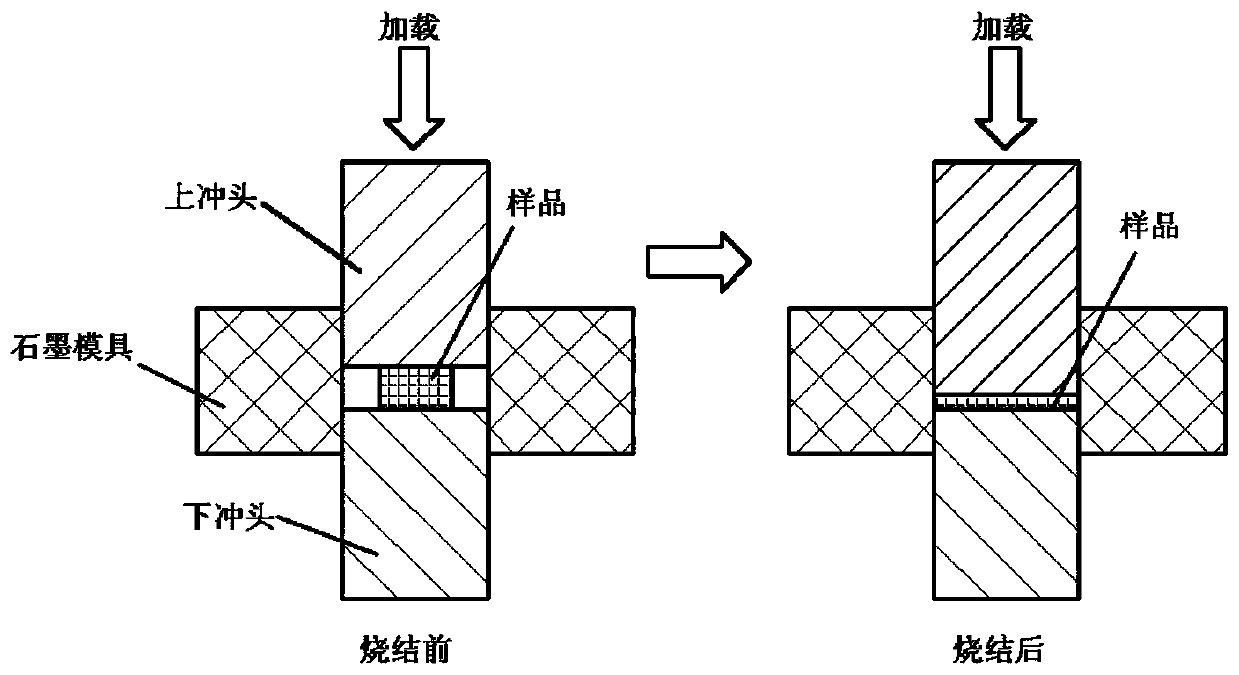

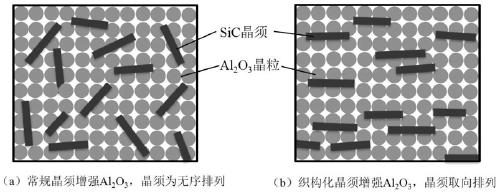

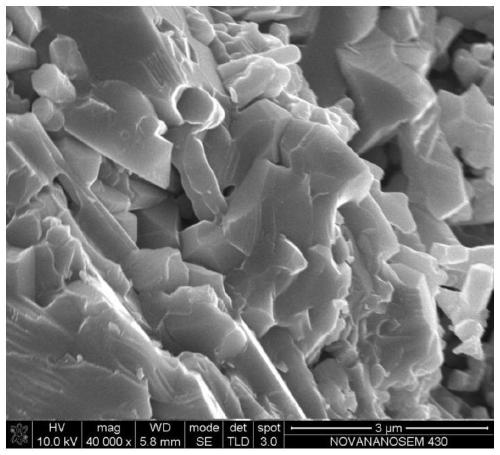

[0044] (4) Hot-press flow sintering: use the hot-press flow sintering method to make the biscuit obtained in step (3) flow and sinter in a two-dimensional direction perpendic...

Embodiment 2

[0046] Example 2 Al 2 o 3 -SiC whisker-Y 2 o 3

[0047] (1) Mixing: 70 grams of Al 2 o 3 , 25 grams of SiC whiskers (diameter 0.5um, aspect ratio 10-30), 5 grams of sintering aid Y 2 o 3 Add it into absolute ethanol to make a mixed powder, and disperse it ultrasonically for 10 minutes; then put it into grinding balls with a ball-to-material ratio of 1:1, and ball mill for 10 hours to obtain a slurry;

[0048] (2) Drying: put the ball-milled slurry into a rotary evaporator and dry at 60°C; after the powder is dried, pass through a 60-mesh sieve to obtain a mixed powder;

[0049] (3) Forming: the sieved mixed powder is formed by dry pressing with a steel mold with a diameter of 50 mm, and the pressure is 30 MPa to obtain a block of a corresponding shape, and then cold isostatic pressing is performed at a pressure of 200 MPa to obtain a green body;

[0050] (4) Hot-press flow sintering: use the hot-press flow sintering method to make the biscuit obtained in step (3) flow ...

Embodiment 3

[0051] Example 3 Al 2 o 3 -SiC whisker-Y 2 o 3 -MgO

[0052] (1) Mixing: 70 grams of Al 2 o 3 , 20 grams of SiC whiskers (diameter 0.5um, aspect ratio 10-30), 4 grams of sintering aid Y 2 o 3 , 6 grams of sintering aid MgO were added in absolute ethanol, made into mixed powder, ultrasonically dispersed for 10 minutes; then put into grinding balls, the ball-to-material ratio was 1:1, and ball milled for 10 hours to obtain a slurry;

[0053] (2) Drying: put the ball-milled slurry into a rotary evaporator and dry at 60°C; after the powder is dried, pass through a 60-mesh sieve to obtain a mixed powder;

[0054] (3) Forming: the sieved mixed powder is formed by dry pressing with a steel mold with a diameter of 50 mm, and the pressure is 30 MPa to obtain a block of a corresponding shape, and then cold isostatic pressing is performed at a pressure of 200 MPa to obtain a green body;

[0055] (4) Hot-press flow sintering: use the hot-press flow sintering method to make the bis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com