High-porosity mullite whisker porous ceramic tube and preparing method

A technology of mullite whisker and high porosity, which is applied in the field of mullite whisker porous ceramic tube and its preparation, can solve the problems of powder agglomeration, low porosity of green mullite whisker, etc. Reduced aggregate agglomeration and uniform slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

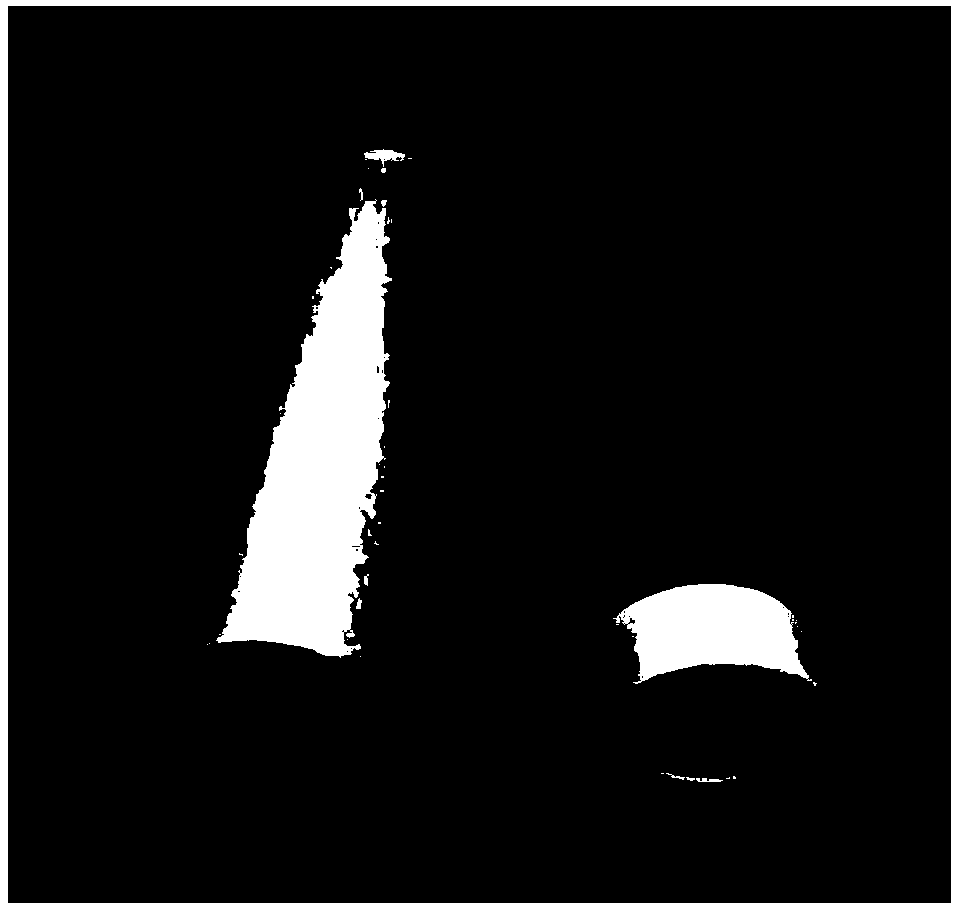

Image

Examples

Embodiment 1

[0023] Embodiment 1: with kaolin and Al(OH) 3 Preparation of mullite whisker ceramic tube as raw material and ammonium tungstate as catalyst

[0024] First, 20% binder PESF and 3% plasticizer PVP are dissolved in 30g NMP solution until the dissolution is complete; then, 45g kaolin, Al(OH) 3 Mix the powder with ammonium tungstate, after adding the powder each time, after ball milling for 5 hours, add again, the mass ratio of the materials in the mixed powder is based on the chemical formula (3Al 2 o 3 2SiO2 2 ) 0.8 (WO 3 ) 0.2 Calculation: After all the powders are added, ball mill for 24 hours to obtain a ceramic casting solution with certain fluidity.

[0025] Inject the casting liquid into the ceramic tube forming device (see utility model patent 204699591U for the forming device), and use the device to extrude, so that the casting liquid contacts with the flocculant water and solidifies due to the phase inversion process; then, soak in the flocculant for 24 hours , t...

Embodiment 2

[0031] Embodiment 2: with coal gangue and Al(OH) 3 as raw material, AlF 3 Fabrication of Mullite Whisker Ceramic Tubes for Catalysts

[0032] First, dissolve ~20% binder PESF and ~3% plasticizer PVP in ~30g NMP solution until the dissolution is complete; then, add ~45g coal gangue, Al(OH) 3 and AlF 3 Mix the powder, after adding the powder each time, after ball milling for 5 hours, add again, the mass ratio of the materials in the mixed powder is based on the chemical formula 3Al 2 o 3 2SiO2 2 and 3-10wt% AlF 3 Catalyst content calculation; after all powders are added, ball mill for 24-48 hours to obtain ceramic casting liquid with certain fluidity.

[0033] Inject the casting liquid into the ceramic tube forming device (see utility model patent 204699591U for the forming device), and use the device to extrude, so that the casting liquid contacts with the flocculant water and solidifies due to the phase inversion process; then, soak in the flocculant for 24 hours As abo...

Embodiment 3

[0034] Embodiment 3: with fly ash and Al(OH) 3 as raw material, AlF 3 Fabrication of Mullite Whisker Ceramic Tubes for Catalysts

[0035] First, dissolve ~20% binder PESF and ~3% plasticizer PVP in ~30g NMP solution until the dissolution is complete; then, add ~45g fly ash, Al(OH) 3 and AlF 3 Mix the powder, after adding the powder each time, after ball milling for 5 hours, add again, the mass ratio of the materials in the mixed powder is based on the chemical formula 3Al 2 o 3 2SiO2 2 and 3-10wt% AlF 3 Catalyst content calculation; after all powders are added, ball mill for 24-48 hours to obtain ceramic casting liquid with certain fluidity.

[0036] Inject the casting liquid into the ceramic tube forming device (see utility model patent 204699591U for the forming device), and use the device to extrude, so that the casting liquid contacts with the flocculant water and solidifies due to the phase inversion process; then, soak in the flocculant for 24 hours As above, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com