Method for preparing titanium pigment from novel-process-flow titanium slag and titanium concentrated ore through mixed acidolysis

A technology of titanium concentrate and titanium dioxide, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of continuous production process, quality limitation of titanium dioxide, and difficulty in large-scale production, so as to save consumption and low price , the effect of saving iron powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

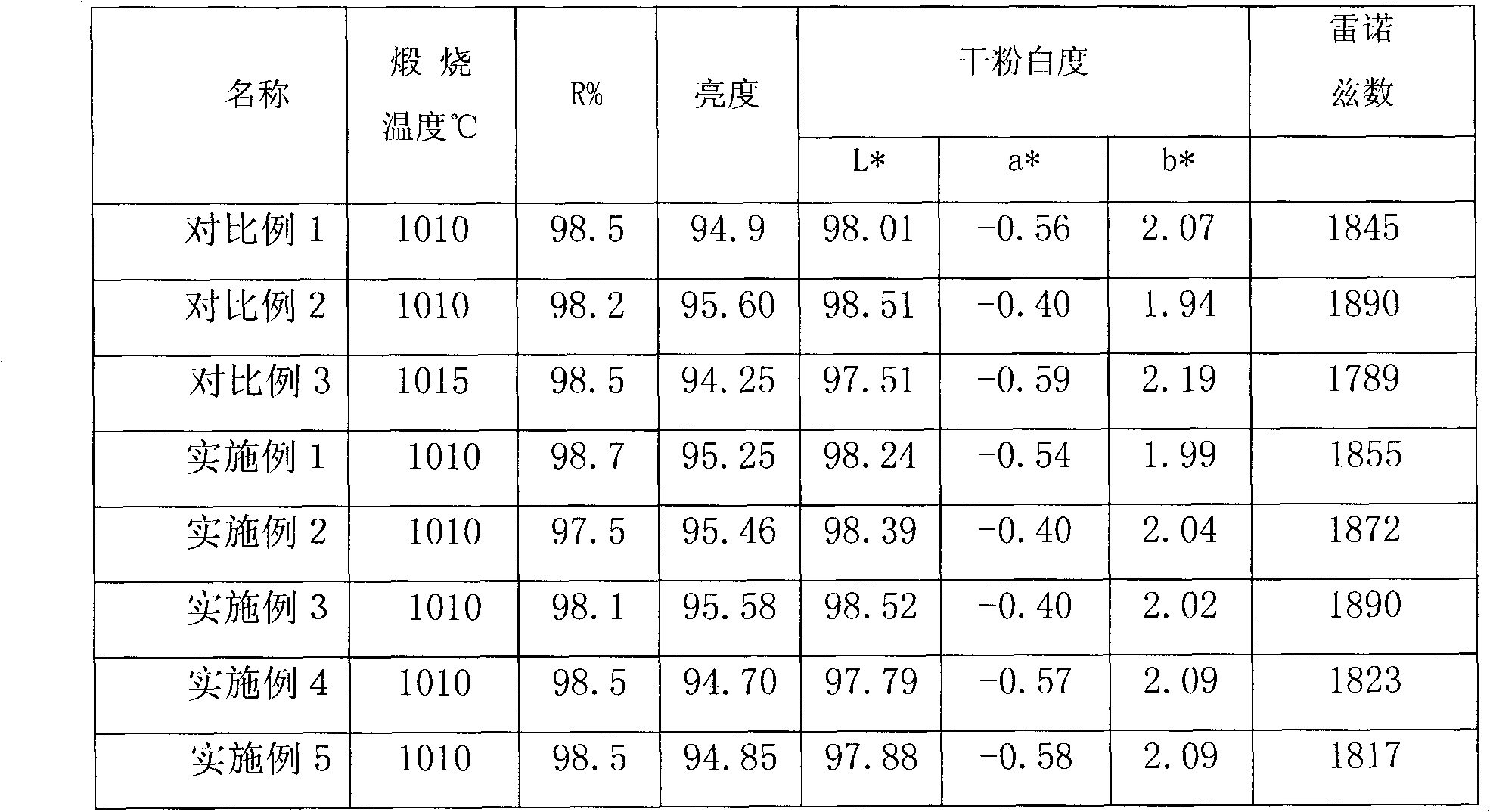

Examples

Embodiment 1

[0041] Put 1683 grams of 98% concentrated sulfuric acid into a 5000mL beaker according to the acid-ore ratio of 1.65, and crush 60g to less than 15% of particles larger than 45 microns in the new process titanium slag and 940g of titanium slag crushed to particles larger than 45 microns to less than 15% The titanium concentrate is mixed evenly, then the mixed mineral powder is added to the concentrated sulfuric acid while stirring, and the mixture is evenly mixed. Add 281g of water to adjust the reaction acid concentration to 84%; then heat up while stirring. When the temperature rises to 150°C, Stop heating and allow the reaction to proceed spontaneously to form a solid phase mixture;

[0042] The resulting solid phase mixture was matured at a temperature of 180°C for 1.5h, leached with 2500mL of water, maintained at a temperature of 70°C, leached for 2.5h and then added with 25g iron powder to continue leaching for a total of 4h.

[0043] Add flocculant formaldehyde dimethylamine...

Embodiment 2

[0047] Put 1683 grams of 98% concentrated sulfuric acid into a 5000mL beaker according to the acid-to-ore ratio of 1.65, first mix 150g of the new process titanium slag and 910g of the pulverized titanium concentrate, and then add the mixed mineral powder while stirring. In the concentrated sulfuric acid, mix well, add 281g water to adjust the reaction acid concentration to 84%; then heat up while stirring. When the temperature rises to 150°C, stop heating, the reaction will proceed spontaneously, and finally a solid phase mixture will be formed.

[0048] The resulting solid phase mixture was matured at 180°C for 2h, leached with 2500mL of water, maintained at 70°C, and the leaching time was 4 hours. After leaching for 2.5h, 20g iron powder was added for reduction.

[0049] After leaching is completed, the flocculant formaldehyde dimethylamine modified polypropionamide (same as Comparative Example 1) is added for sedimentation, filtered and separated to obtain a clear titanium solut...

Embodiment 3

[0052] Put 1735 grams of 98% concentrated sulfuric acid into a 5000mL beaker according to the acid-ore ratio of 1.7, first mix 180g of the new process titanium slag and 880g of the pulverized titanium concentrate (mixing ratio 20%), and then add while stirring In the concentrated sulfuric acid, mix well, then add 241g of water to adjust the reaction acid concentration to 86%; then heat up while stirring. When the temperature rises to 150°C, stop heating to proceed spontaneously and finally generate a solid phase mixture.

[0053] The resulting solid phase mixture was matured at 220°C for 1.5h, and 2800mL of water was added for leaching. The leaching temperature was maintained at 75°C. The leaching time was 3.5 hours. After leaching for 2.5h, 20g iron powder was added for reduction.

[0054] After leaching is completed, the flocculant formaldehyde dimethylamine modified polypropionamide (same as Comparative Example 1) is added for sedimentation, filtered and separated to obtain a cle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com