On-line graying point judging device in titanium white production

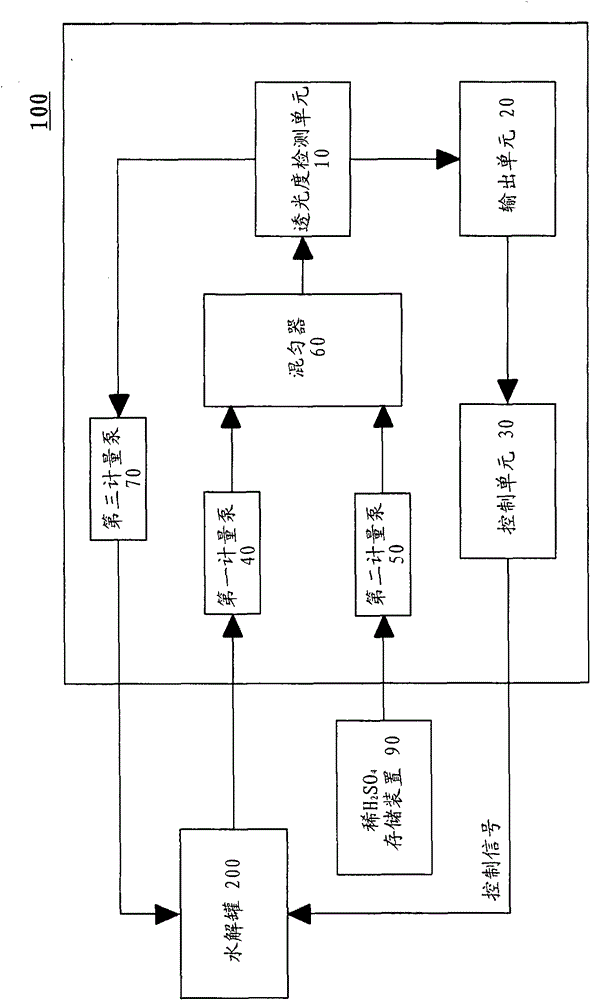

A judging device and a technology for graying point, which are applied to the device for online judging graying point, a device field in the production of titanium dioxide, to achieve the effects of narrow particle size distribution, good pigment performance, and elimination of quality fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

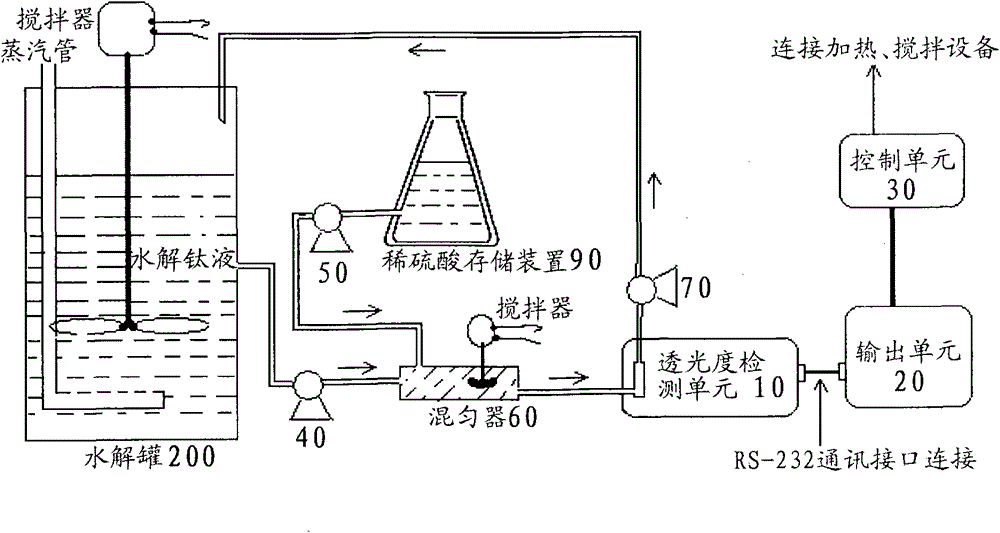

[0029] The UV723PCS spectrophotometer is used as the transmittance detection unit of the present invention, and the transmittance of the diluted titanium solution is detected after the above modification, and a computer is used as the output unit. dilute H 2 SO 4 The mass concentration of the dilute sulfuric acid solution in the storage device is 10%, and the flow ratio of the first metering pump and the second metering pump is adjusted to 1:100.

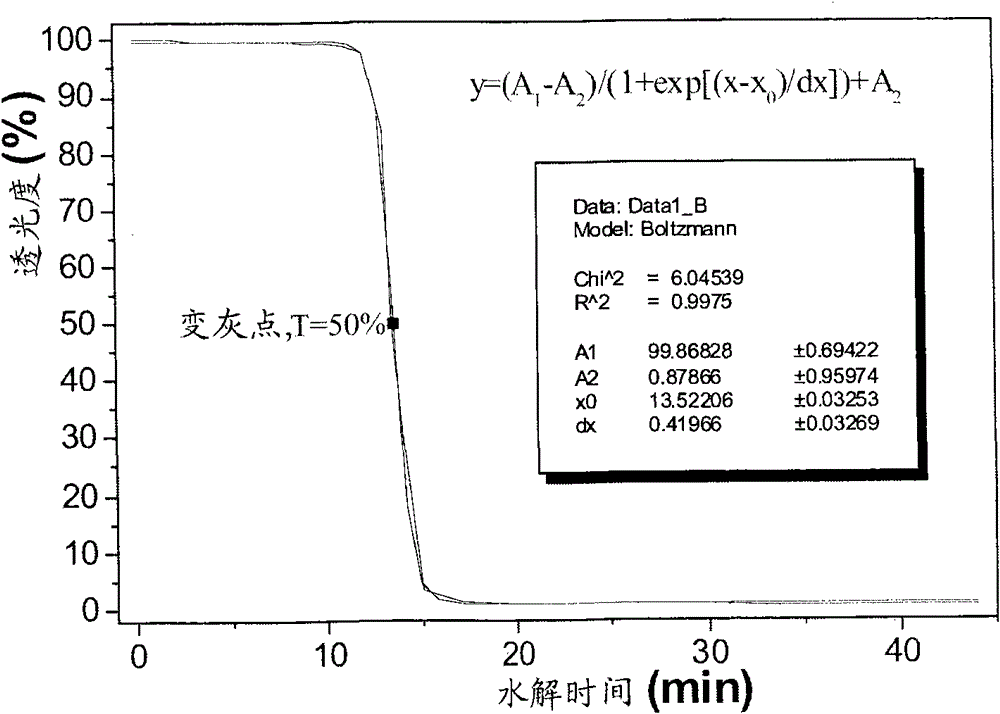

[0030] Take deionized water with 25% volume of the titanium solution and add it into the hydrolysis tank as bottom water, and preheat to 96° C. under stirring. The titanium solution preheated to 96°C, with a concentration of 230g / L and an F value of 1.85 was added to the hydrolysis tank at a uniform speed within 17 minutes, and the temperature of the hydrolysis system was maintained at 96°C during the feeding process. After the feeding is complete, the hydrolysis system is heated to the first boiling point (about 106° C.), and the...

Embodiment 2

[0034] Except adopting the single-chip microcomputer as the output unit, adopt the judging device of the online graying point identical with embodiment 1 to measure the light transmittance of the hydrolyzed titanium solution. Except that the flow ratio of the first metering pump and the second metering pump is adjusted to 1:200, the same process as in Example 1 is used to produce titanium dioxide, and the diluted titanium solution when the titanium solution reaches the first boiling point is used as a reference. Compared with the solution, the microcontroller will record the corresponding signal as 1amV. When the signal recorded by the single-chip microcomputer is 0.5amV (at this time, it is the gray point), the single-chip microcomputer immediately outputs a control signal to the control unit to stop the heating and stirring of titanium dioxide production. It took 11.2 minutes from the first boiling point to the graying point, and then aged for 25 minutes.

[0035] The parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com