Automatic control method for extraction amount of cover plate glass

A cover glass and controller technology, which is applied in program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of large fluctuation range of lead-out quantity, achieve the effects of reducing fluctuation range, eliminating quality fluctuation, and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

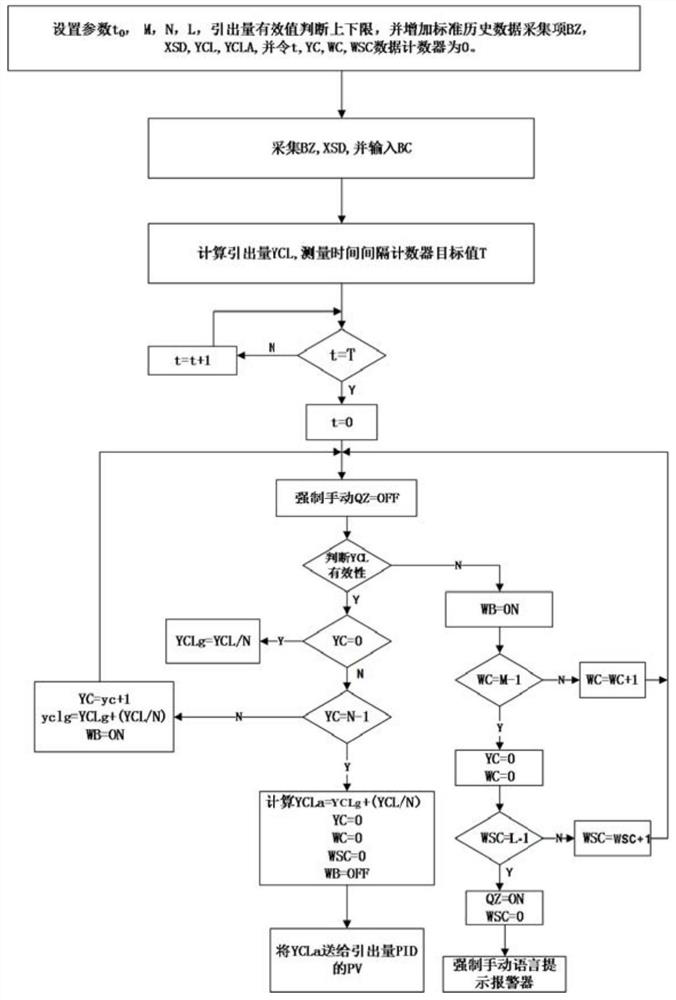

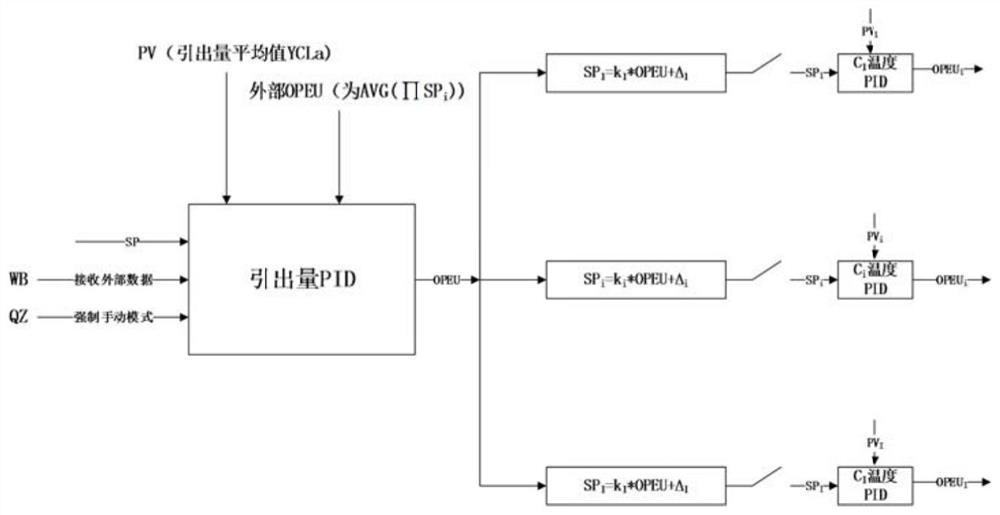

[0077] Step 1, according to the actual production experience, set the execution period t of the control module CM in the DCS system 0 And the target value of the effective data quantity taken by the lead-out data group is a valid data group is N, the target value of the invalid data quantity is M when the lead-out data group is an invalid data group, and the target value of the number of continuous invalid data groups of the lead-out automatic control is L ;

[0078] Define the target value of the measurement time interval counting of two continuous glass plates in the latter process as T; the measurement time interval counter is t, the valid data counter is yc, the invalid data counter is wc, the invalid data group counter is wsc, and the plate weight bz, traction roll Linear speed xsd, lead-out amount ycl, effective data average value ycla of lead-out data group are added as standard historical data collection items, and data records are carried out; the upper and lower limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com