Technique for producing elastomer of thermoplastic polyurethane

A thermoplastic polyurethane and production process technology, which is applied in the field of polymer preparation, can solve the problems of large amounts of static electricity and dust, large investment, and poor product quality, and achieve the effects of no energy consumption, expanding customer base, and improving reputation

Active Publication Date: 2010-11-24

WANHUA CHEM GRP CO LTD

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Compared with the external circulation blending technology adopted in the early stage, the homogenization silo has the following disadvantages: (1) Large investment and high energy consumption, the external circulation increases power equipment and energy consumption, and increases Production cost; (2) The quality of the product is poor, the material has undergone multiple cycles, and the wear is serious, which affects the product quality; (3) The safety is poor, due to the long-term cycle, the material will generate a lot of static electricity and dust, causing environmental pollution and endangering the human body healthy

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

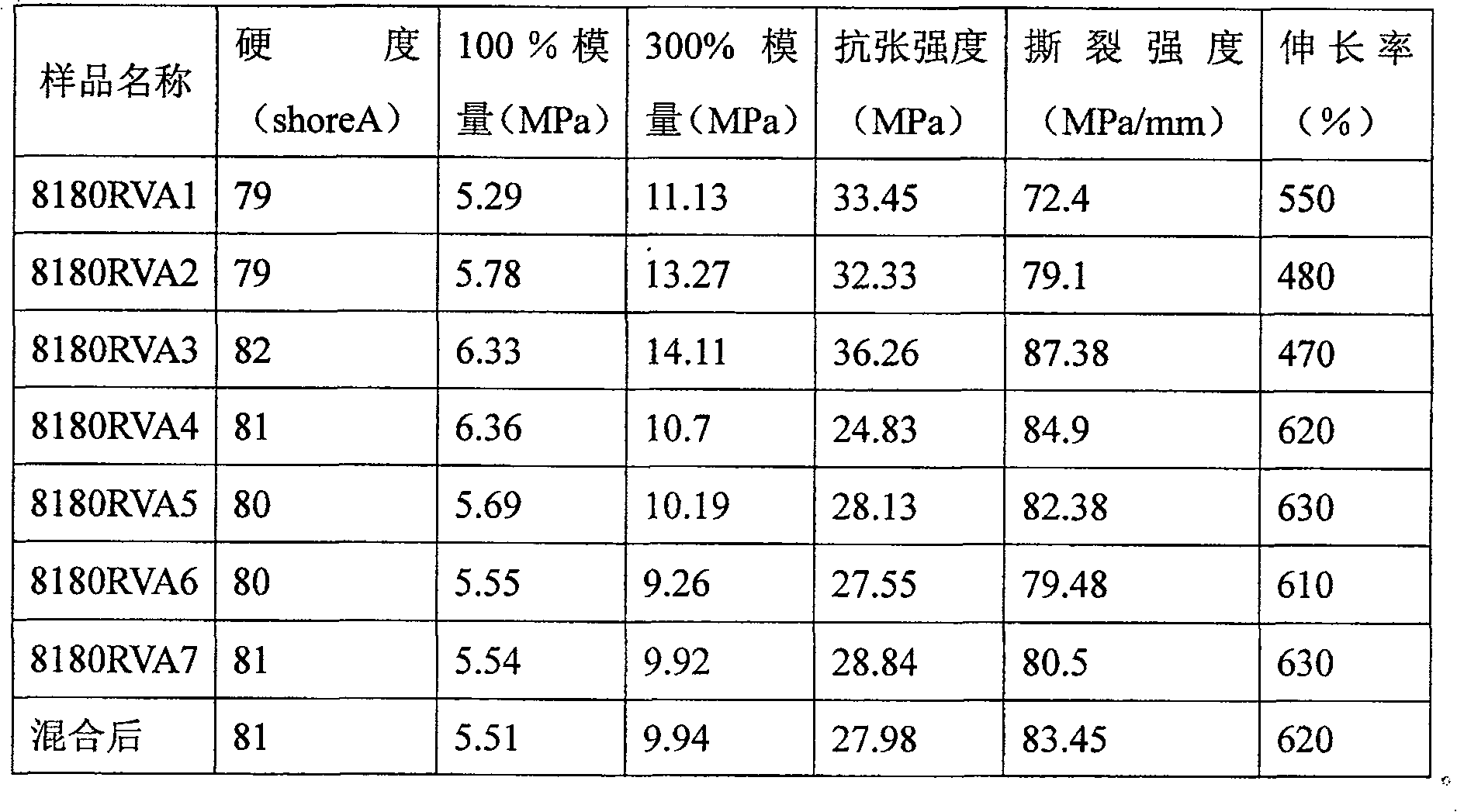

This invention relates to a process for producing thermoplastic polyurethane elastomer. The process comprises: adding diisocyanate, macromolecular diol, chain extender and additives into a twin screw extruder, reacting, extruding and granulating, sending to a drying and aging system, sending to a homogenization bunker, mixing, homogenizing to obtain stable TPU granules, and packaging. The method utilizes the homogenization bunker to homogenize different batches of TPU granules, thus can eliminate quality fluctuations among different batches.

Description

A kind of thermoplastic polyurethane elastomer production process technical field The invention relates to a production process of thermoplastic polyurethane elastomer, which belongs to the technical field of polymer preparation. Background technique For the production of thermoplastic polyurethane elastomer (TPU), due to the particularity of the polymer itself, although the process parameter setting and formula of the same brand product are controlled as much as possible, the relevant physical parameters of different batches of products will vary. Certain differences (although all are considered qualified products), the so-called quality fluctuations. Such fluctuations in quality can adversely affect the use of downstream customers. For example, for TPU, downstream customers are mainly spinning, drawing, and injection molding. Due to quality fluctuations, the production of downstream customers is unstable, the drawing film is uneven, thick and thin, easy to break when dr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08G101/00C08G18/72C08G18/48C08G18/08C08G18/42

Inventor 王仁鸿傅桂华张生杨永清刘学栋赵玮王东青王淑静

Owner WANHUA CHEM GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com