Method for producing titanium dioxide

A technology of titanium dioxide and titanium liquid, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of increasing production processes and production costs, and achieve the effects of simplifying production processes, narrow particle size distribution, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

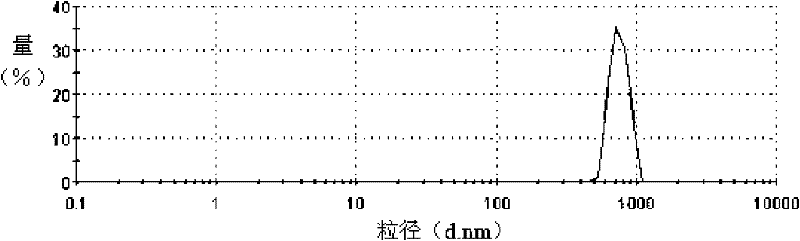

[0039]Embodiment 1 adopts the inventive method to produce titanium dioxide

[0040] Take 29.0ml of deionized water and add it into the hydrolysis pot, and preheat to 96°C while stirring. Add 100ml of hydrolyzed titanium solution preheated to 95°C, with a concentration of 222g / l and an F value of 1.83, into the hydrolysis pot at a constant speed within 17 minutes, and maintain the temperature of the hydrolysis system at 98°C during the feeding process. After the feeding is complete, the hydrolysis system is heated to boiling (about 104° C.), and the heating rate is maintained at 1.20° C. / min. The heating time is 5 minutes, and the system is kept in a slightly boiling state. When the solution turns gray (that is, the gray point), stop heating and stirring, and ripen for 30 minutes. After the aging was completed, the system was heated and boiled again (about 105° C.) under stirring, and the heating rate was kept at 2.0° C. / min, and the heating time was 12 minutes, and the system...

Embodiment 2

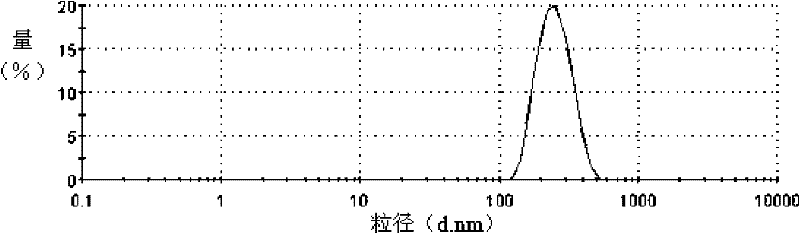

[0042] Embodiment 2 adopts the inventive method to produce titanium dioxide

[0043] Use sulfuric acid solution to adjust the pH of the deionized water to 8.30, take 26.0ml into the hydrolysis pot, and preheat to 94°C while stirring. Add 100ml of hydrolyzed titanium solution preheated to 95°C, with a concentration of 202g / l and an F value of 1.85, into the hydrolysis pot at a constant speed within 17 minutes, and maintain the temperature of the hydrolysis system at 95°C during the feeding process. After the feeding is complete, the hydrolysis system is heated to boiling (about 102.5° C.), and the heating rate is maintained at 1.07° C. / min. The heating time is 7 minutes, and the system is kept in a slightly boiling state. When the solution turns gray (that is, the gray point), stop heating and stirring, and ripen for 30 minutes. After the aging was completed, the system was heated to boiling (about 103.5° C.) under stirring, and the heating rate was maintained at 2.4° C. / min. ...

Embodiment 3

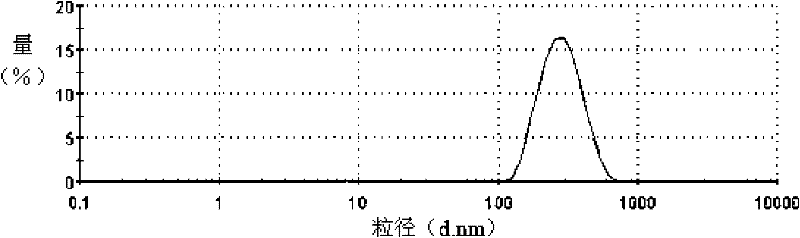

[0045] Embodiment 3 adopts the inventive method to produce titanium dioxide

[0046] Use sulfuric acid solution to adjust the pH of the deionized water to 4.80, take 23.0ml into the hydrolysis pot, and preheat to 96°C while stirring. Add 100ml of hydrolyzed titanium solution preheated to 95°C, with a concentration of 231g / l and an F value of 1.73, into the hydrolysis pot at a constant speed within 18 minutes, and maintain the temperature of the hydrolysis system at 95.5°C during the feeding process. After the feeding is complete, the hydrolysis system is heated to boiling (about 104.5° C.), and the heating rate is maintained at 1.41° C. / min. The heating time is 6.4 minutes, and the system is kept in a slightly boiling state. When the solution turns gray (that is, the gray point), stop heating and stirring, and ripen for 30 minutes. After the aging was completed, the system was heated again to boiling (about 105.5° C.) under stirring, and the heating rate was kept at 2.5° C. / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com