Preparation method of high-activity calcined seed crystal

A calcined seed crystal, high activity technology, applied in chemical instruments and methods, titanium oxide/hydroxide, inorganic chemistry, etc., can solve problems such as insufficient activity of calcined seed crystals, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

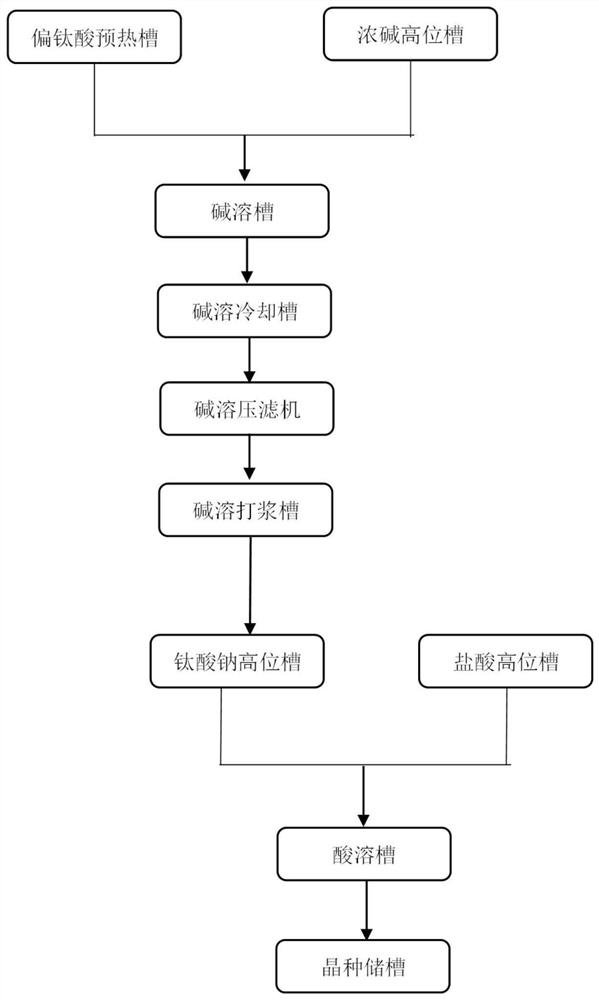

[0028] A preparation method for highly active calcined seed crystals, comprising the following steps:

[0029] Step 1: Preheat the metatitanic acid to 65°C in the metatitanic acid preheating tank, preheat the lye to 115°C in the concentrated alkali high level tank,

[0030] Step 2: Add the preheated metatitanic acid and lye into the alkali dissolution tank at a mass ratio of 1:1.6 and react for 90 minutes to obtain sodium titanate. The concentration of metatitanic acid is 361.5g / L, and the concentration of lye is 620.3 g / L;

[0031] Step 3: Cool the sodium titanate to 60°C, and pump the cooled sodium titanate into an alkali-soluble filter press for washing for 210 minutes to obtain a filter cake;

[0032] Step 4: Put the filter cake into an alkali-soluble beating tank, add desalted water for beating, and obtain a sodium titanate slurry with a concentration of 200 g / L;

[0033] Step 5: Add sodium titanate slurry and hydrochloric acid to the acid-dissolving tank at a mass rati...

Embodiment 2

[0035] A preparation method for highly active calcined seed crystals, comprising the following steps:

[0036] Step 1: Preheat the metatitanic acid to 60°C in the metatitanic acid preheating tank, preheat the lye to 110°C in the concentrated alkali high level tank,

[0037] Step 2: Put the preheated metatitanic acid and lye into the alkali dissolution tank at a mass ratio of 1:1.6 to react for 90 minutes to obtain sodium titanate, the concentration of metatitanic acid is 355.7g / L, and the concentration of lye is 619.58 g / L;

[0038] Step 3: Cool the sodium titanate to 60°C, and pump the cooled sodium titanate into an alkali-soluble filter press for washing for 210 minutes to obtain a filter cake;

[0039] Step 4: Put the filter cake into an alkali-soluble beating tank, add desalted water for beating, and obtain a sodium titanate slurry with a concentration of 210 g / L;

[0040] Step 5: Add sodium titanate slurry and hydrochloric acid to the acid-dissolving tank at a mass rati...

Embodiment 3

[0042] A preparation method for highly active calcined seed crystals, comprising the following steps:

[0043] Step 1: Preheat the metatitanic acid to 55°C in the metatitanic acid preheating tank, preheat the lye to 105°C in the concentrated alkali high level tank,

[0044] Step 2: Put the preheated metatitanic acid and lye into the alkali dissolution tank at a mass ratio of 1:1.6 to react for 80 minutes to obtain sodium titanate, the concentration of metatitanic acid is 360.4g / L, and the concentration of lye is 630g / L;

[0045] Step 3: Cool the sodium titanate to 55°C, and pump the cooled sodium titanate into an alkali-soluble filter press for washing for 210 minutes to obtain a filter cake;

[0046] Step 4: Put the filter cake into an alkali-soluble beating tank, add desalted water for beating, and obtain a sodium titanate slurry with a concentration of 190 g / L;

[0047] Step 5: Add sodium titanate slurry and hydrochloric acid into the acid-dissolving tank at a mass ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com