Method for judging graying point in titanium dioxide production

A gray point and titanium dioxide technology, applied in the field of judging the gray point, can solve the problems of inaccurate judgment and quality fluctuation of titanium dioxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

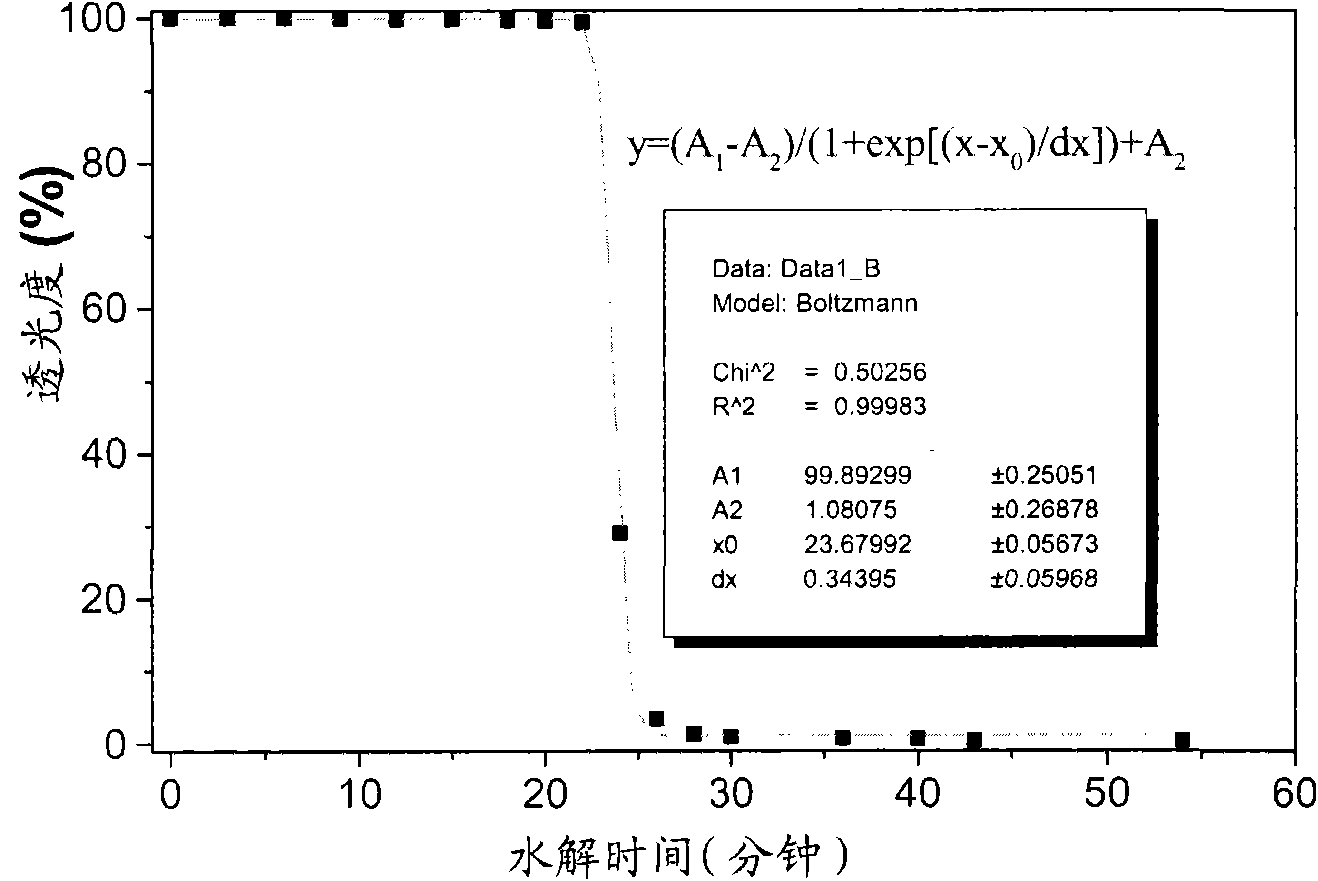

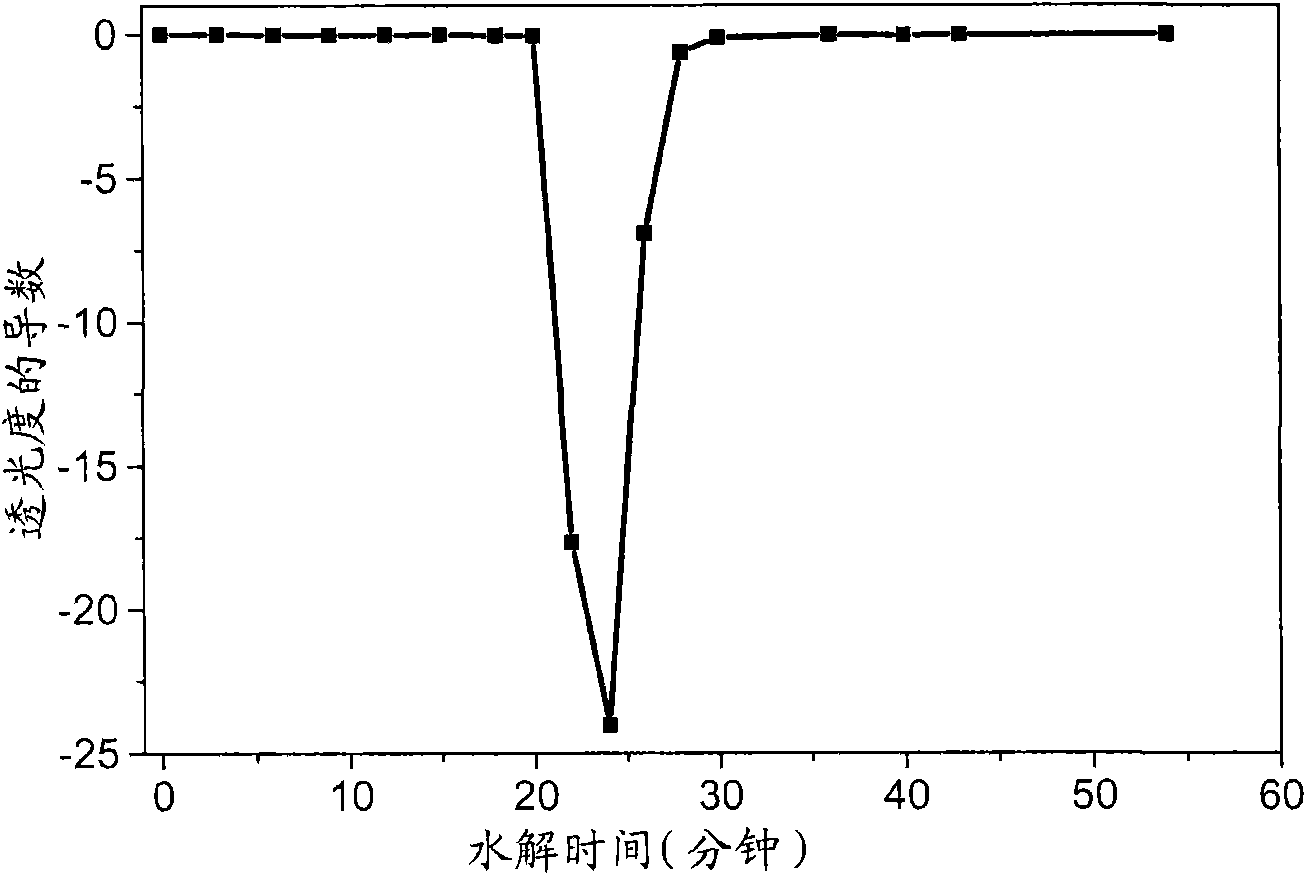

[0034] Embodiment 1 adopts the inventive method to produce titanium dioxide

[0035] Take 25.0 mL of deionized water and add it into the hydrolysis pot as the bottom water, and preheat to 96°C while stirring. Add 100mL of titanium solution preheated to 95°C, with a concentration of 229g / L and an F value of 1.86, into the hydrolysis pot at a uniform speed within 17 minutes, and maintain the temperature of the hydrolysis system at 96°C during the feeding process. After the feeding is complete, the hydrolysis system is heated to the first boiling point (about 106° C.), and the heating rate is maintained at 1.00° C. / min. The heating time is 10 minutes, and the system is kept in a slightly boiling state. Get the hydrolyzed slurry and measure its light transmittance according to the implementation step (4). The sulfuric acid aqueous solution used is 10%, and the dilution volume ratio is 1: 100. When the system turns gray, stop heating and stirring, and ripen for 30 minutes. After a...

Embodiment 2

[0037] Embodiment 2 adopts the inventive method to produce titanium dioxide

[0038] Add 27.0 mL of deionized water into the hydrolysis pot, and preheat to 94°C with stirring. Add 100mL of titanium solution preheated to 95°C, with a concentration of 201g / L and an F value of 1.92, into the hydrolysis pot at a uniform speed within 18 minutes, and maintain the temperature of the hydrolysis system at 94°C during the feeding process. After the feeding is complete, the hydrolysis system is heated to the first boiling point (about 105° C.), and the heating rate is maintained at 1.1° C. / min. The heating time is 10 minutes, and the system is kept in a slightly boiling state. Get the hydrolyzed slurry and measure its light transmittance by the implementation step (4), the sulfuric acid aqueous solution used is 15%, and the dilution volume ratio is 1: 50, when the system changes to the point of graying, stop heating and stirring. It took a total of 20 minutes for gray point and 25 minut...

Embodiment 3

[0040] Embodiment 3 adopts the inventive method to produce titanium dioxide

[0041] Add 23.0 mL of deionized water into the hydrolysis pot, and preheat to 98°C while stirring. Add 100mL of titanium liquid preheated to 98°C, with a concentration of 233g / L and an F value of 1.83, into the hydrolysis pot at a constant speed within 16 minutes, and maintain the temperature of the hydrolysis system at 98°C during the feeding process. After the feeding is complete, the hydrolysis system is heated to the first boiling point (about 106.5° C.), and the heating rate is maintained at 0.77° C. / min. The heating time is 11 minutes, and the system is kept in a slightly boiling state. Get the hydrolyzed slurry and measure its light transmittance according to implementation step (4), the sulfuric acid aqueous solution used is 5%, and the dilution volume ratio is 1: 150, and when the system changes to the gray point, stop heating and stirring, from the end of feeding to the change It took a to...

PUM

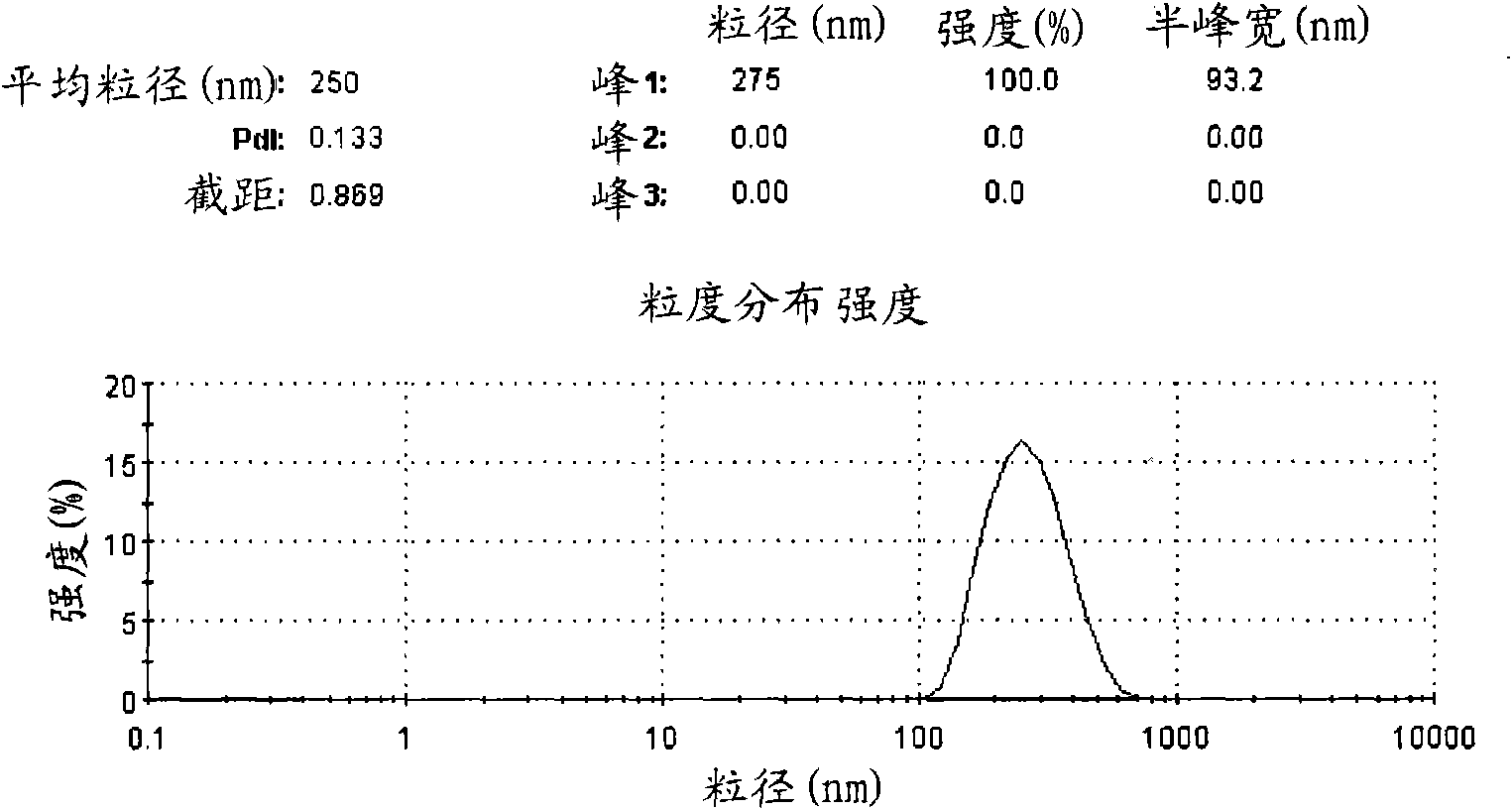

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com