Regeneration method for heavy oil hydro-treating catalyst

A heavy oil hydrogenation and catalyst technology, applied in catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high cost of waste catalyst treatment, environmental pollution, poor catalyst regeneration effect, etc., to achieve It is conducive to full recovery, avoiding excessive damage, and improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

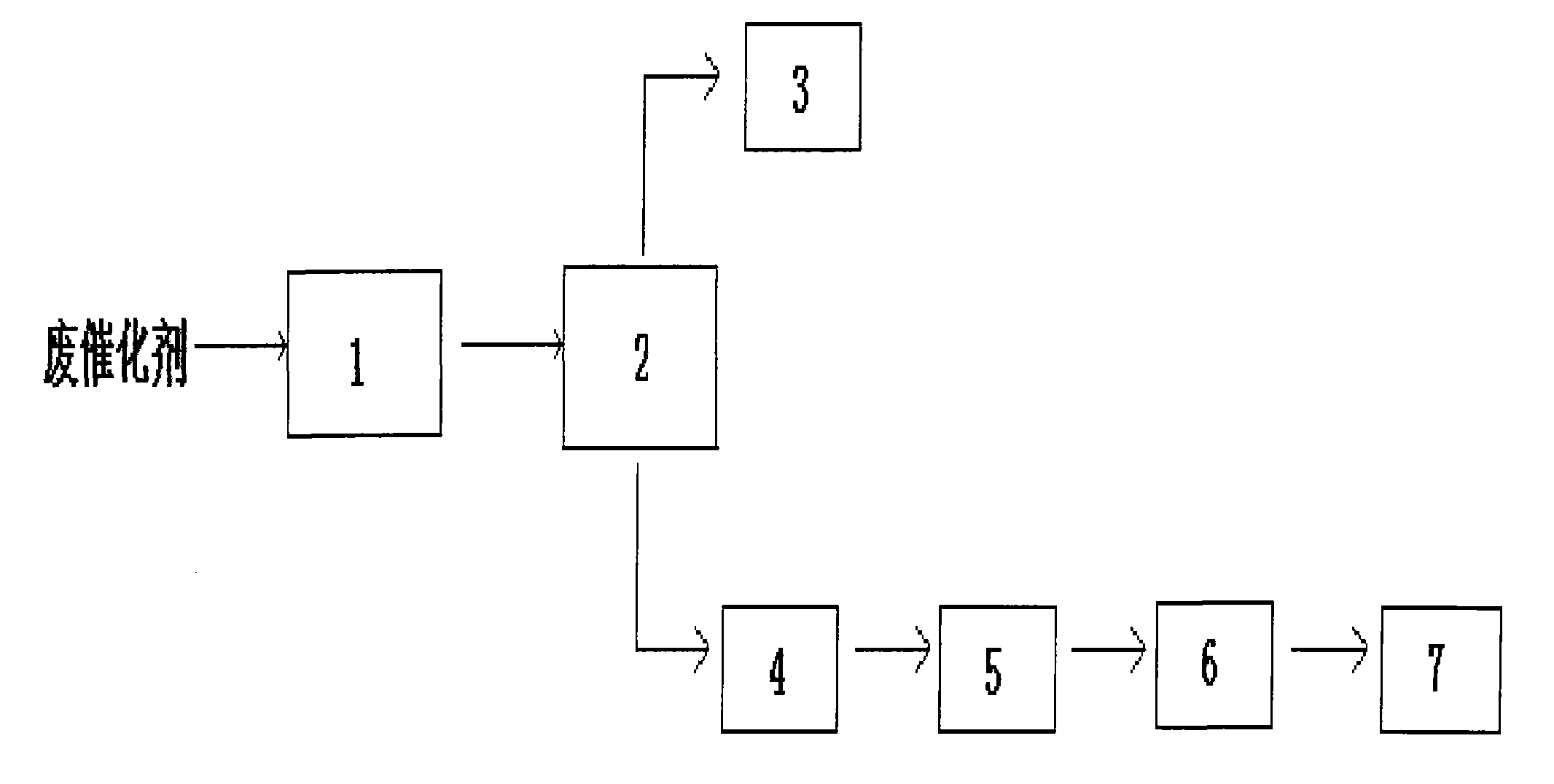

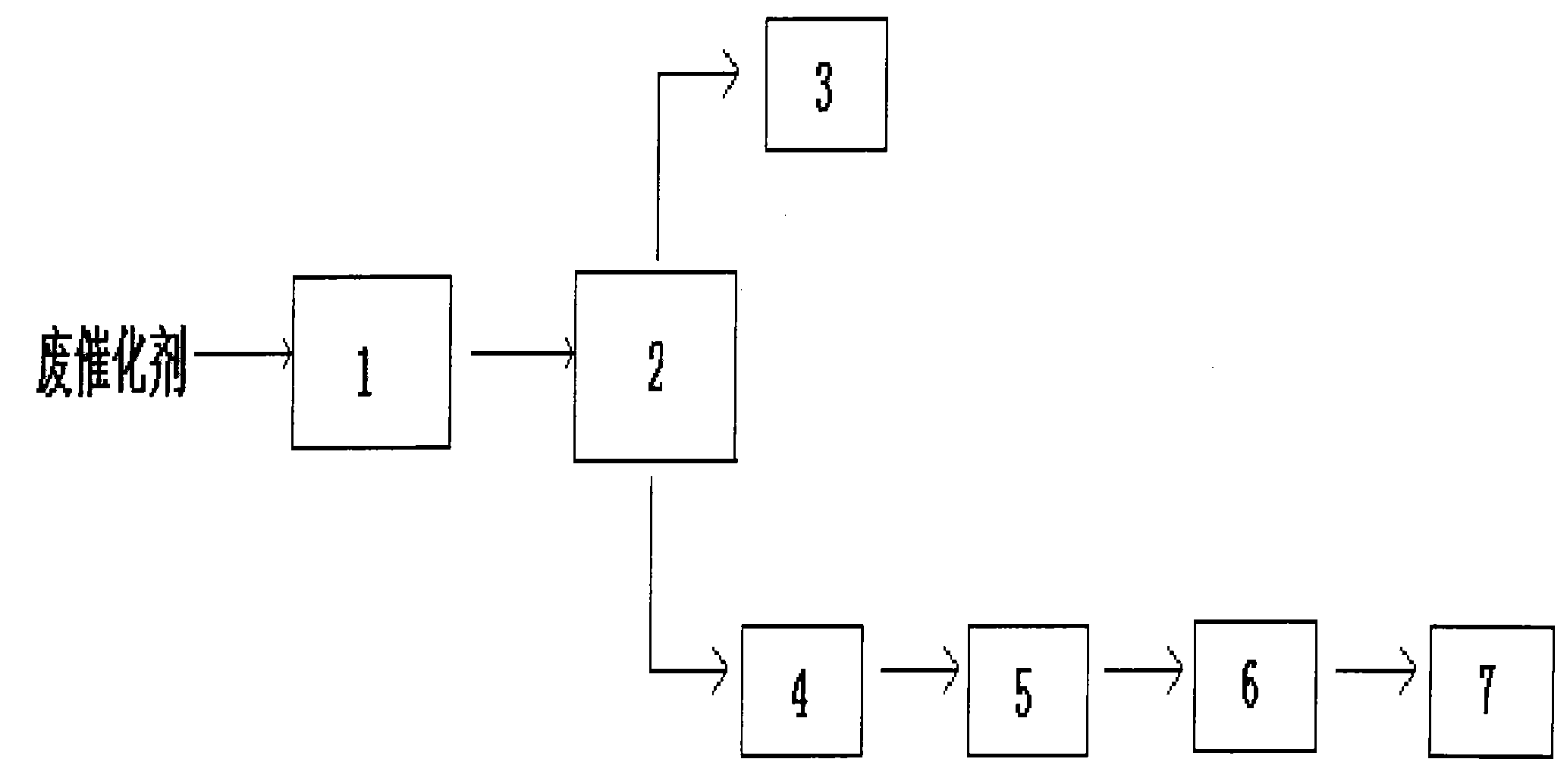

Method used

Image

Examples

Embodiment 1

[0026] The deactivated residual oil hydrotreating catalyst is first dry-distilled at 450°C until no obvious gas is generated, and then washed with 0.2mol / L hydrochloric acid solution for 15 minutes. The temperature of the hydrochloric acid solution washing is 50°C. The dosage is 8L / Kg, then washed twice with water, dried and roasted at 500°C until the CO in the roasting tail gas 2 The volume concentration is lower than 0.03%. The analysis shows that the pore volume, specific surface area and other indicators of the regenerated catalyst are close to those of the fresh catalyst, and the removal rate of deposited metal impurities is about 82%. The regenerated catalyst is evaluated in a small experimental device for hydrogenation of residual oil, and the activity of the fresh catalyst is taken as 100%. According to the calculation, the activity of the regenerated catalyst reaches 92%, which can be used again.

Embodiment 2

[0028] The deactivated residual oil hydrotreating catalyst is dry-distilled at 500°C until no obvious gas is produced, and then washed with 0.4mol / L hydrochloric acid solution for 30 minutes. The temperature of the hydrochloric acid solution is 30°C, and the ratio of hydrochloric acid solution to catalyst is The dosage is 15L / Kg, then washed twice with water, dried and roasted at 450°C until the CO in the roasting tail gas 2 The volume concentration is lower than 0.03%. The analysis shows that the pore volume, specific surface area and other indicators of the regenerated catalyst are close to those of the fresh catalyst, and the removal rate of deposited metal impurities is about 85%. The regenerated catalyst is evaluated in a small experimental device for hydrogenation of residual oil, and the activity of the fresh catalyst is taken as 100%. According to statistics, the activity of the regenerated catalyst reaches 93%, which can be used again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com