Continuous pickling method and continuous pickling device

A pickling device and pickling technology, used in workpiece surface treatment equipment, metal rolling, manufacturing tools, etc., can solve the problems of difficult quantification, low responsiveness, and inability to suppress the fluctuation of acid concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0100] The present invention will be described more specifically below with reference to examples.

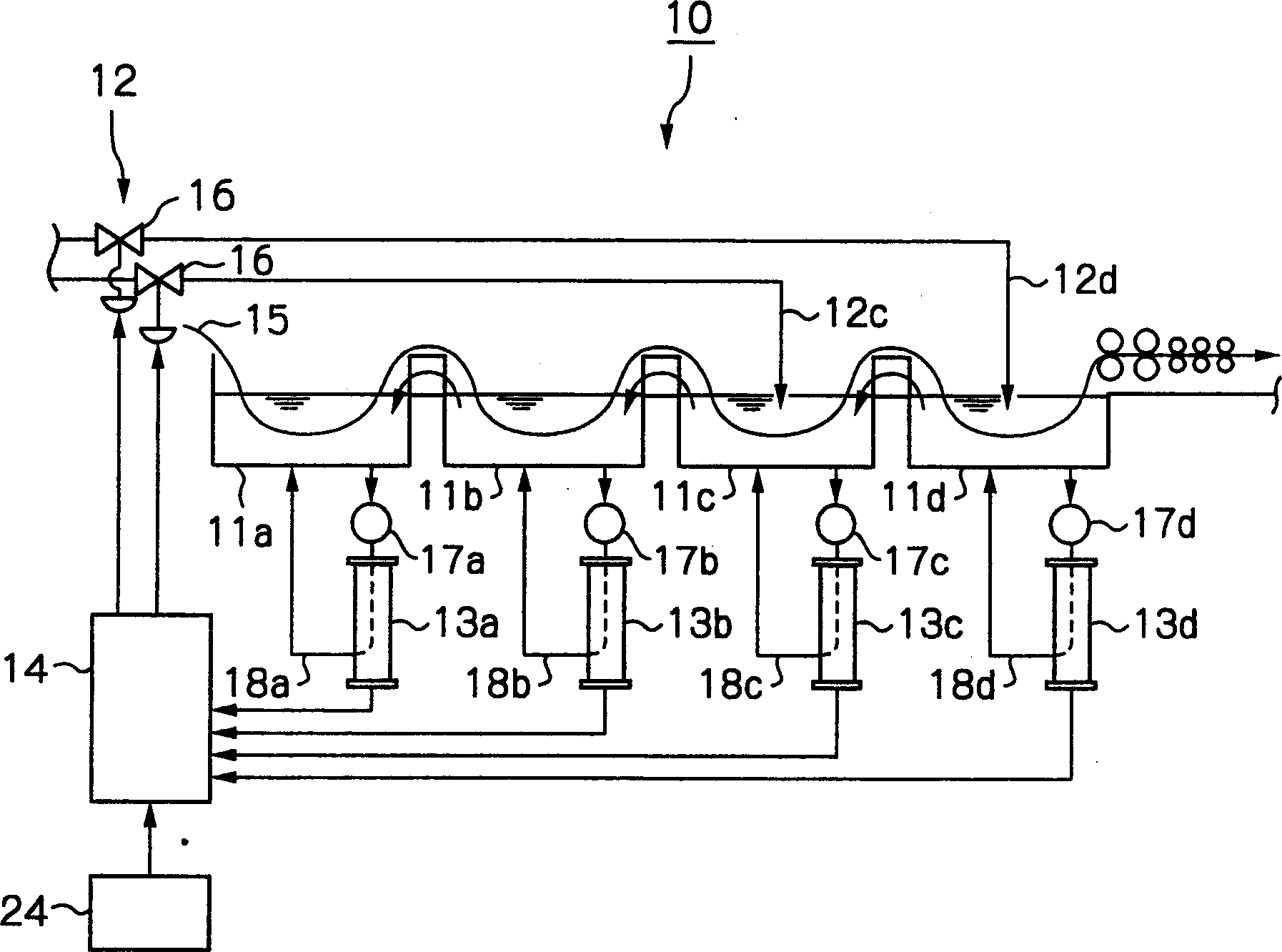

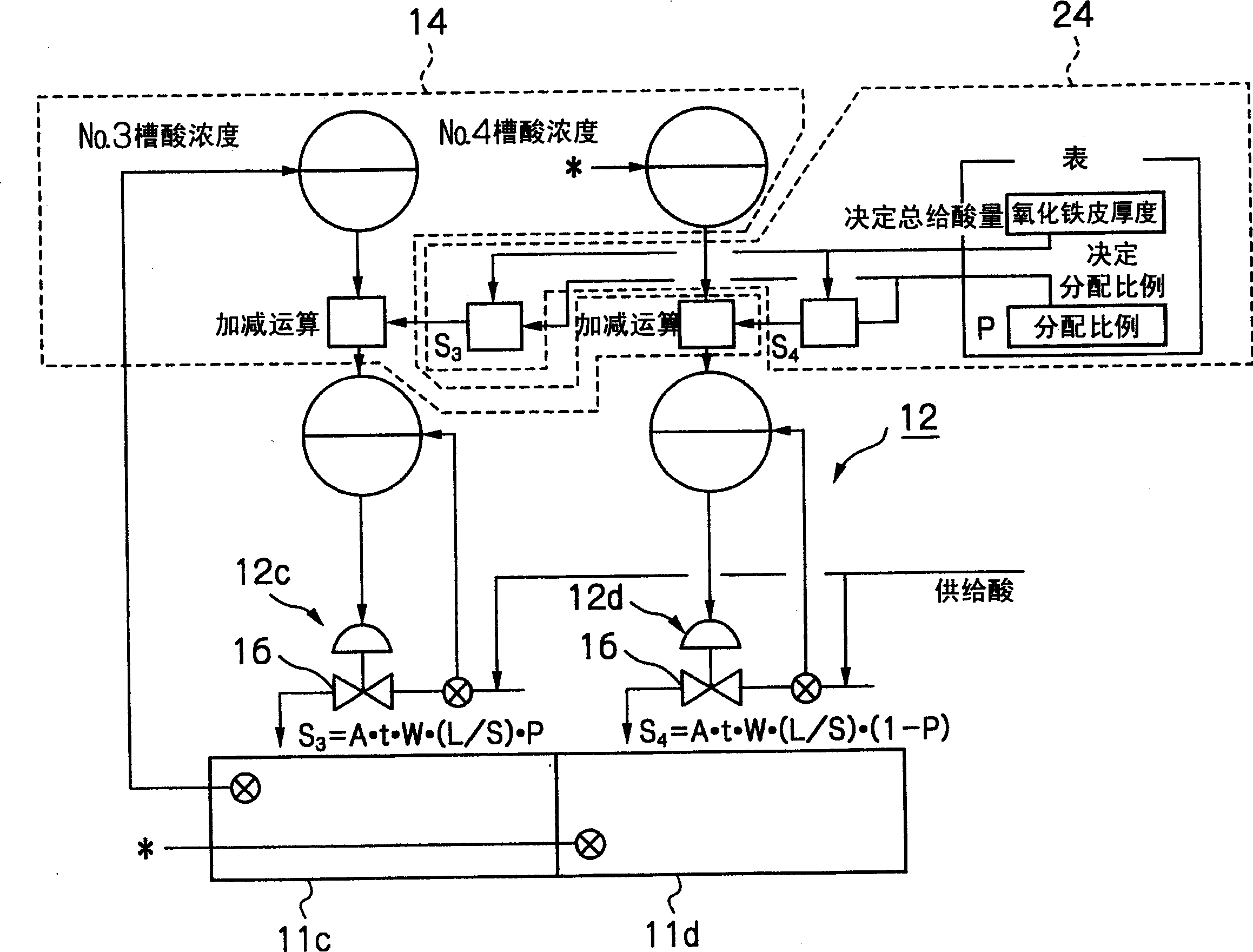

[0101] use figure 1 ~The continuous pickling device 1 that Fig. 5 illustrates (the capacity of each pickling tank 13a~13d is 60 cubic meters, pickling temperature 90 ℃), adopt these continuous pickling methods of the present invention and do comparative example and only do feedback Controlled continuous pickling method, strip 15 was pickled for 24 hours. And when using this type of continuous pickling device for pickling, in order to obtain sufficient time required for the practical evaluation of the present invention, the change value of the acid concentration within 1 hour is usually within a few percent range.

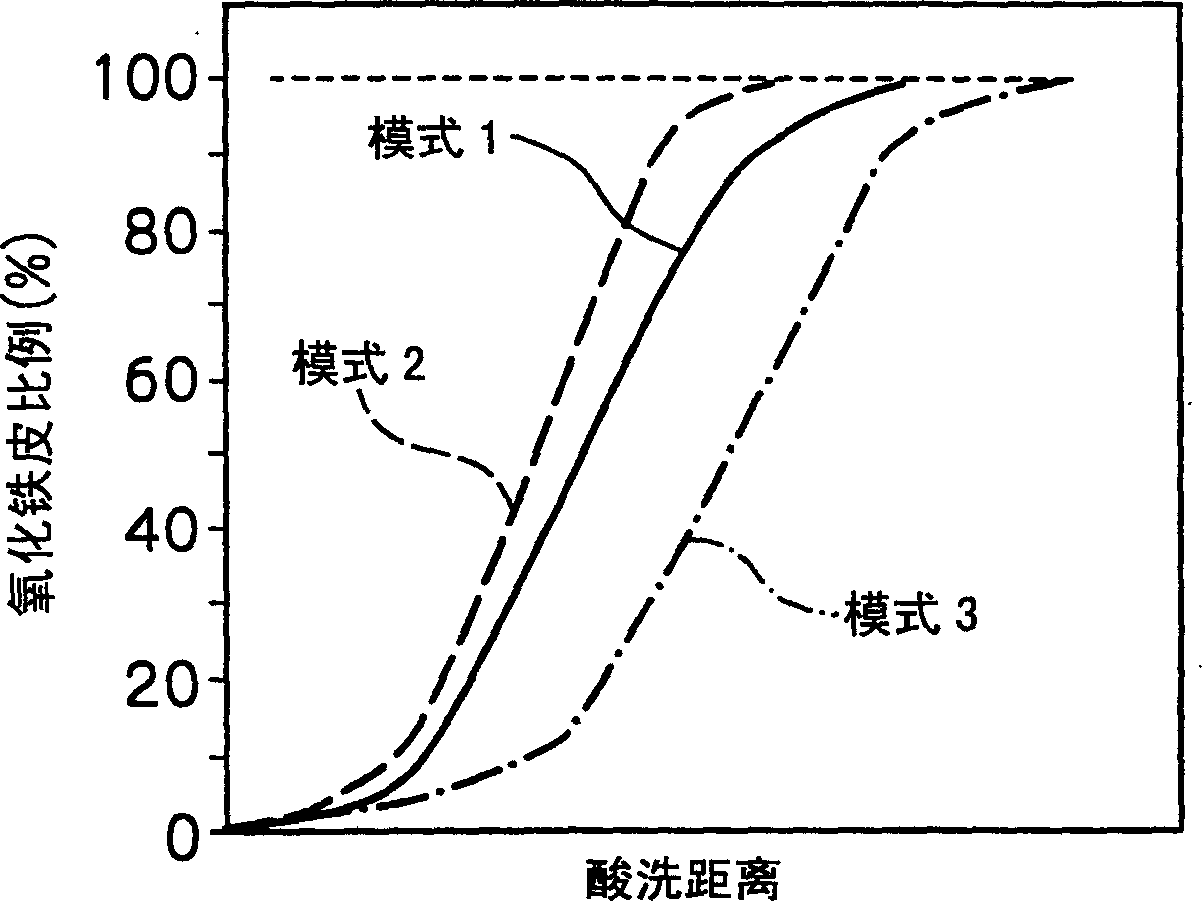

[0102] In this embodiment, the steel types (materials and coil temperatures) produced are divided into five kinds of scale thicknesses and three pickling modes, and the basic test is carried out. Wash in the part memory of each way control device 24. Therefore, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com