Fully-automatic vacuum bicolor one-time foaming forming machine

A foam molding machine, fully automatic technology, applied in the field of fully automatic vacuum two-color one-time foam molding machine, can solve the problems of low product pass rate, difficult vacuuming, etc., and achieve the goal of increasing pass rate, improving efficiency, and stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0015] Embodiments of the invention are:

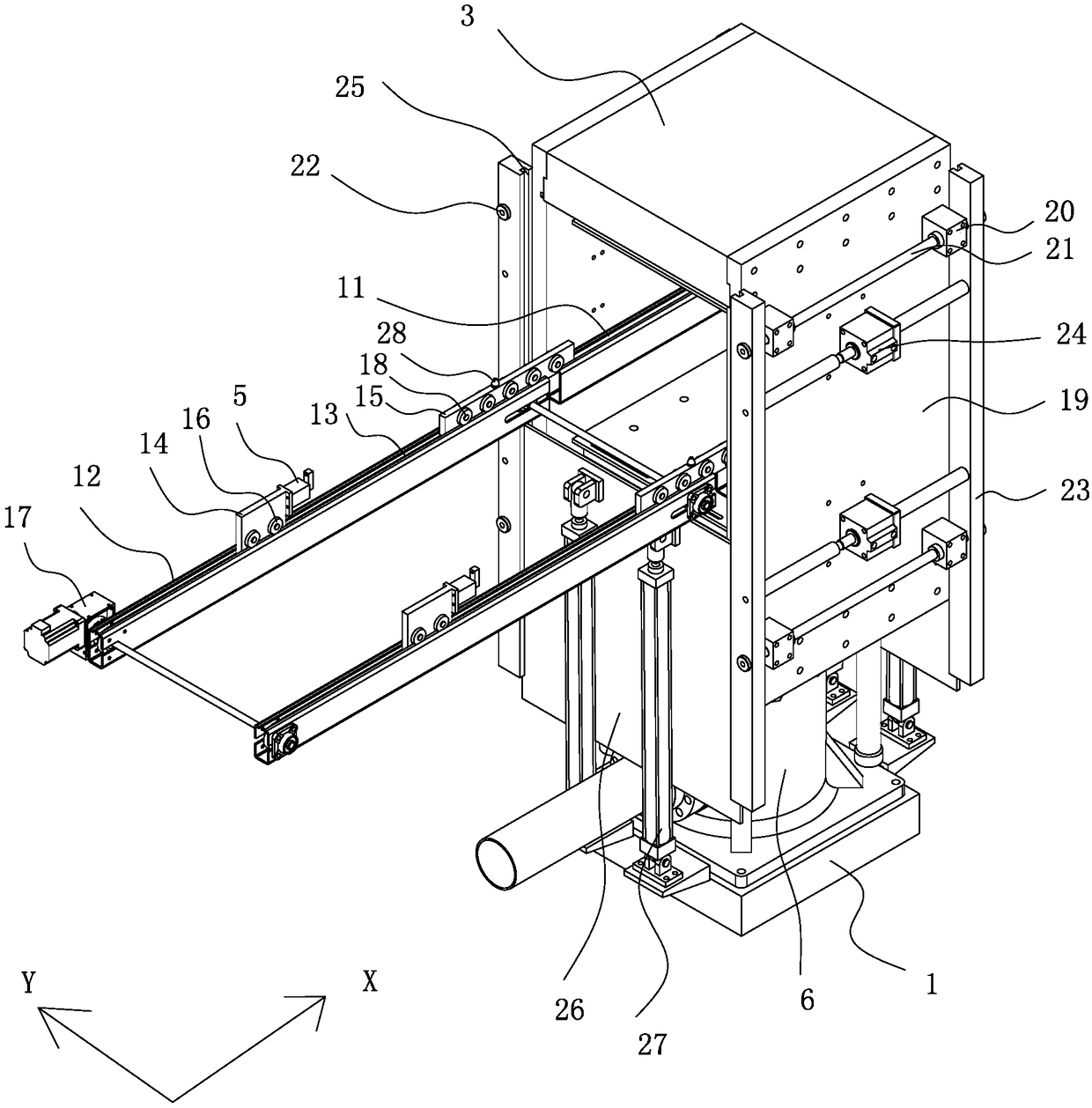

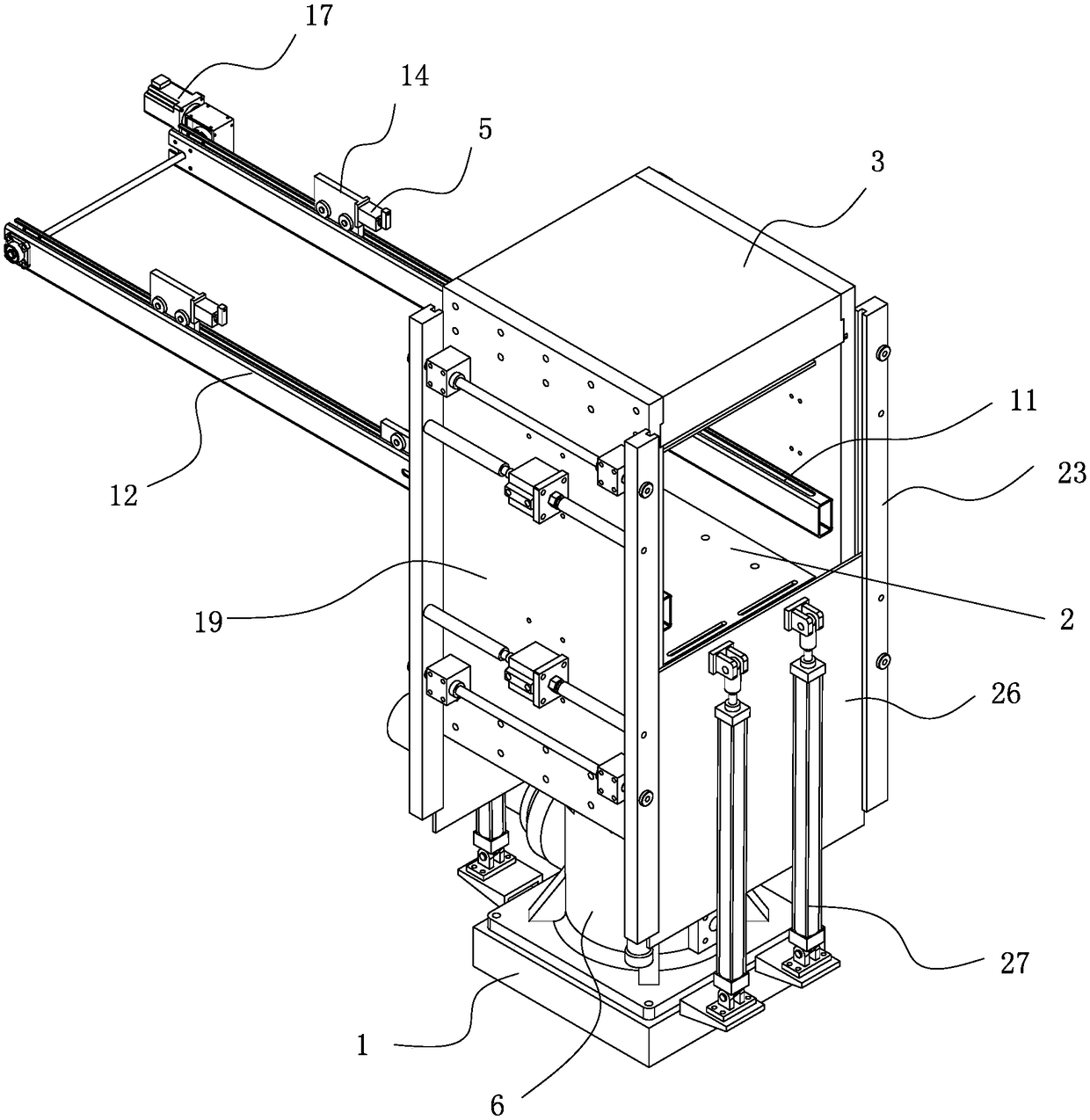

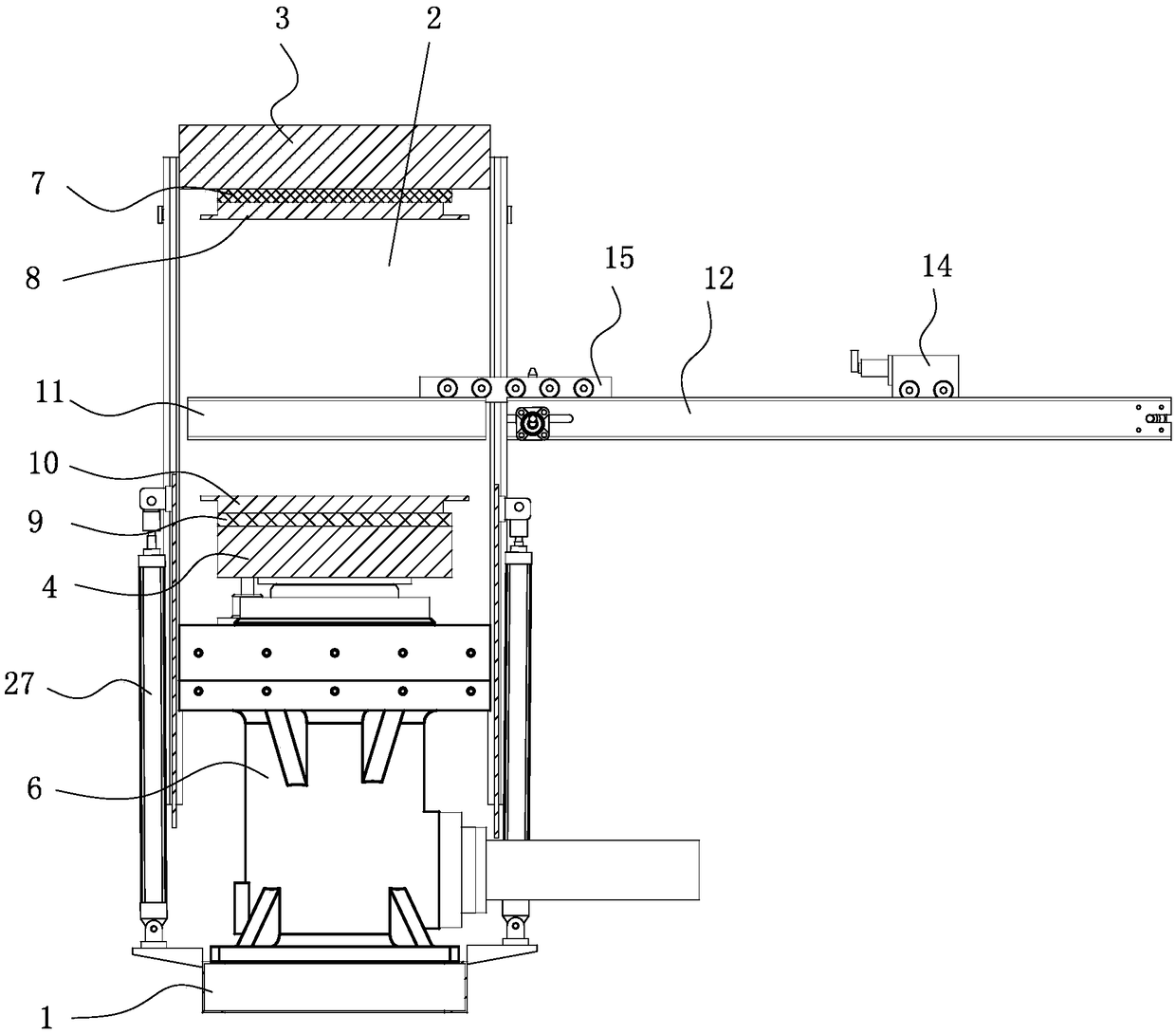

[0016] refer to figure 1 , figure 2 and image 3 , a full-automatic vacuum two-color one-time foaming molding machine, including a frame 1 and a heating station 2 arranged on the frame 1, and the upper and lower parts of the heating station 2 on the frame 1 are respectively provided with upper templates 3 and the lower pressure plate 4, the upper template is located in the heating station 2 and is respectively provided with a first through hole and a second through hole for vacuuming and vacuum breaking, and the lower pressure plate is located on the frame 1 4 is provided with a booster cylinder 6 that drives the lower pressure plate 4 to move up and down. The lower surface of the upper template 3 is provided with an upper heat insulation board 7. The lower surface of the upper heat insulation board 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com