Cyanide-free alkaline copper plating electroplating solution for zinc alloy die castings and preparation method and electroplating method thereof

A cyanide-free alkaline copper plating and electroplating solution technology, which is applied in the direction of improving process efficiency, can solve the problems of low copper plating speed, overcome the poor bonding force, solve the technical problem of slow copper plating speed, and reduce copper plating. The effect of ionic potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

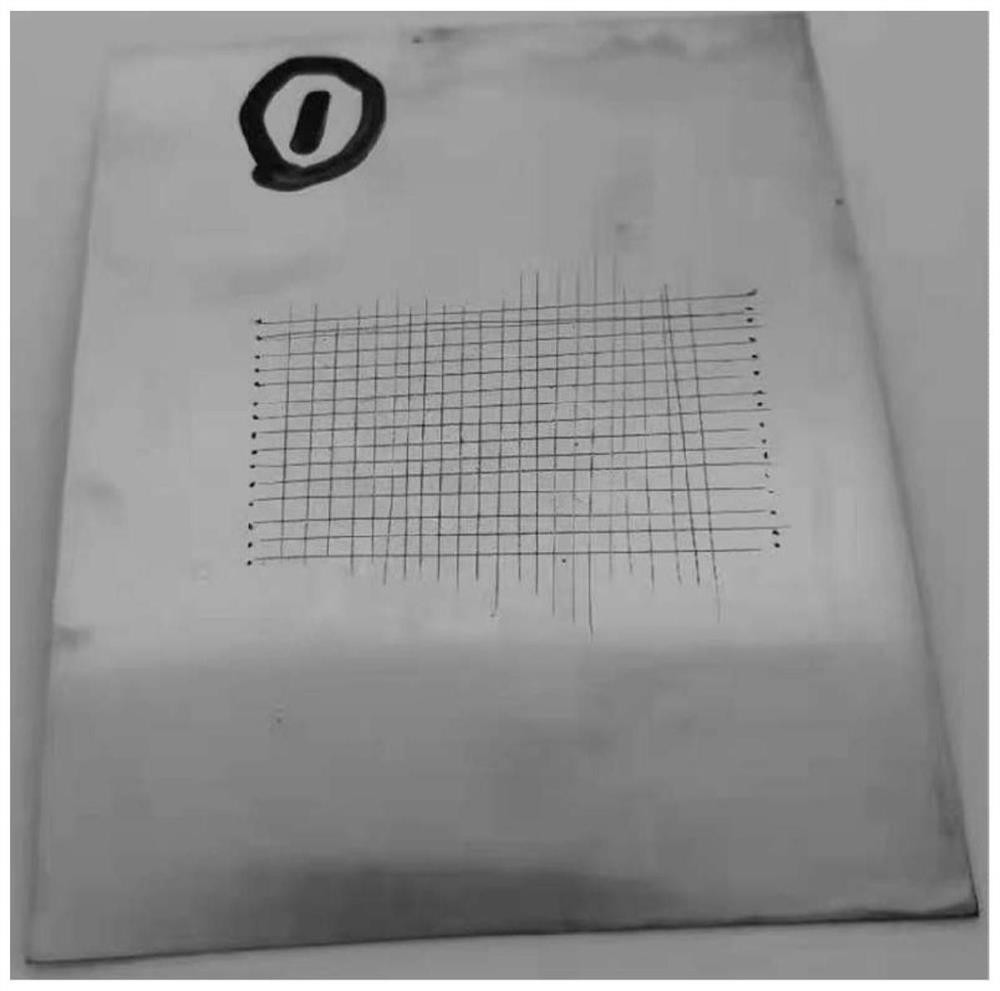

Embodiment 1

[0034] A kind of cyanide-free alkaline copper plating electroplating solution for zinc alloy die castings, each component and content are as table 1;

[0035] The preparation method of the electroplating solution includes the following steps: adding 1 / 2 volume of pure water into the container; adding the complex composition, stirring until dissolved; adding copper salt under stirring, heating to 80°C and stirring to promote A copper complex is formed, and then the complex adsorbent is added and stirred to dissolve. Add the remaining pure water to the working volume and stir evenly, and adjust the pH to 10 with potassium hydroxide to implement electroplating.

[0036] Table 1 is the electroplating solution composition of embodiment 1:

[0037]

[0038]

[0039] Electroplating method: Zinc alloy die castings are degreased and activated in sequence, then placed in the electroplating tank for electroplating, and the current density is set to 2A / dm 2 , Electroplating at roo...

Embodiment 2

[0045] A kind of cyanide-free alkaline copper-plating electroplating solution for zinc alloy die-casting parts, each component and content are as table 2;

[0046] The preparation method of the electroplating solution comprises the following steps: adding a calculated amount of 1 / 2 volume of pure water into the container; adding the complex composition, stirring until dissolved; adding copper salt under stirring, heating to 80°C and stirring to promote A copper complex is formed, and then the complex adsorbent is added and stirred to dissolve. Add the remaining pure water to the working volume and stir evenly, and adjust the pH to 11 with potassium hydroxide to implement electroplating.

[0047] Table 2 is the electroplating solution of embodiment 2:

[0048]

[0049]

[0050] Electroplating method: Zinc alloy die castings are degreased and activated in sequence, then placed in the electroplating tank for electroplating, and the current density is set to 5A / dm 2 , Elec...

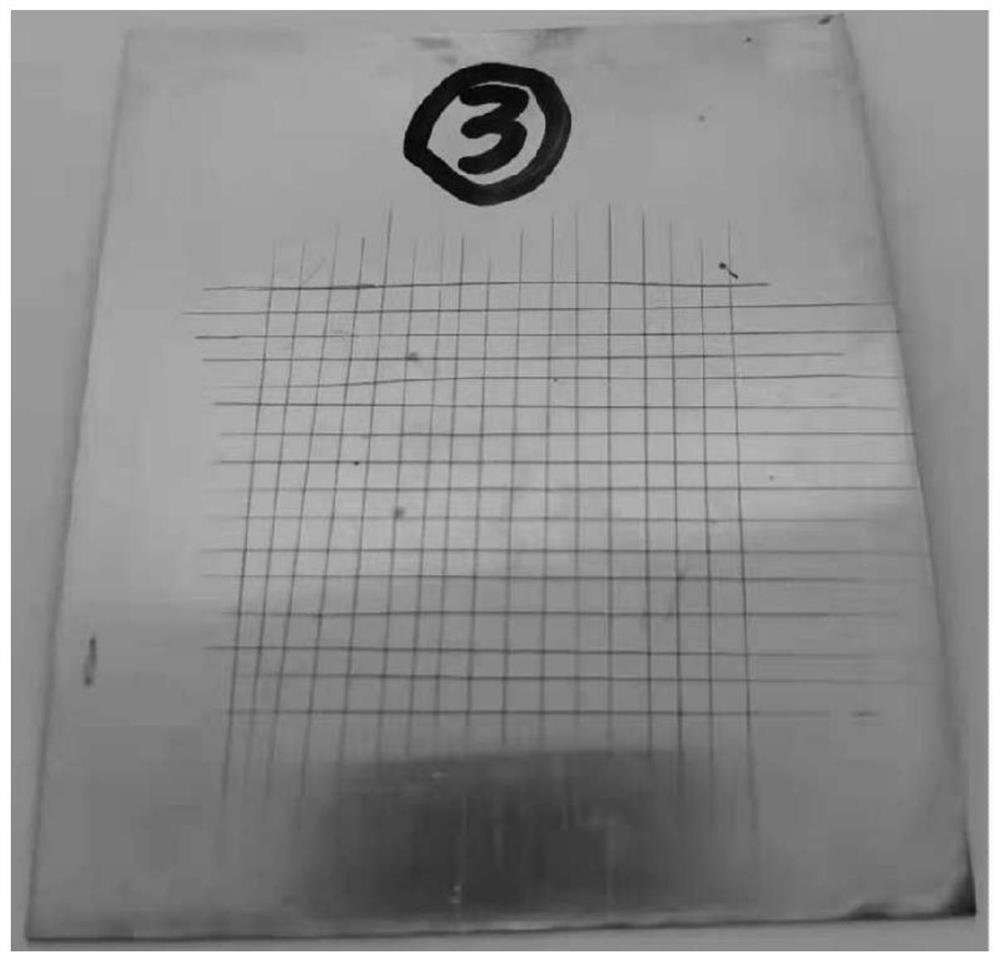

Embodiment 3

[0056] A kind of cyanide-free alkaline copper-plating electroplating solution for zinc alloy die-casting parts, each component and content are as table 3;

[0057] The preparation method of the electroplating solution comprises the following steps: adding a calculated amount of 1 / 2 volume of pure water into the container; adding the complex composition, stirring until dissolved; adding copper salt under stirring, heating to 80°C and stirring to promote A copper complex is formed, and then the complex adsorbent is added and stirred to dissolve. Add the remaining pure water to the working volume and stir evenly, and adjust the pH to 9 with potassium hydroxide to implement electroplating.

[0058] Table 3 is the electroplating solution of embodiment 3:

[0059]

[0060]

[0061] Electroplating method: Zinc alloy die castings are degreased and activated in sequence, then placed in the electroplating tank for electroplating, and the current density is set to 5A / dm 2 , Elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com