Cyanide-free copper plating solution assistant and copper plating solution

A cyanide-free copper plating and additive technology, which is applied in the field of cyanide-free copper plating additives and copper plating solutions, can solve the problems of threats to operators, unfriendly environment, and the inability to obtain copper plating on stainless steel surfaces, etc. Threat, solve the effect of weak binding force, and inhibit the occurrence of displacement reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment discloses a cyanide-free copper plating solution and a preparation method thereof. During preparation, take 1 / 2 of the required amount of pure water, add copper sulfate to it and stir to dissolve, then add sulfuric acid to it under constant stirring, and then respectively Add complexing agent and additives in turn and stir evenly, add the remaining pure water to the required volume to obtain copper plating solution, and then perform electroplating.

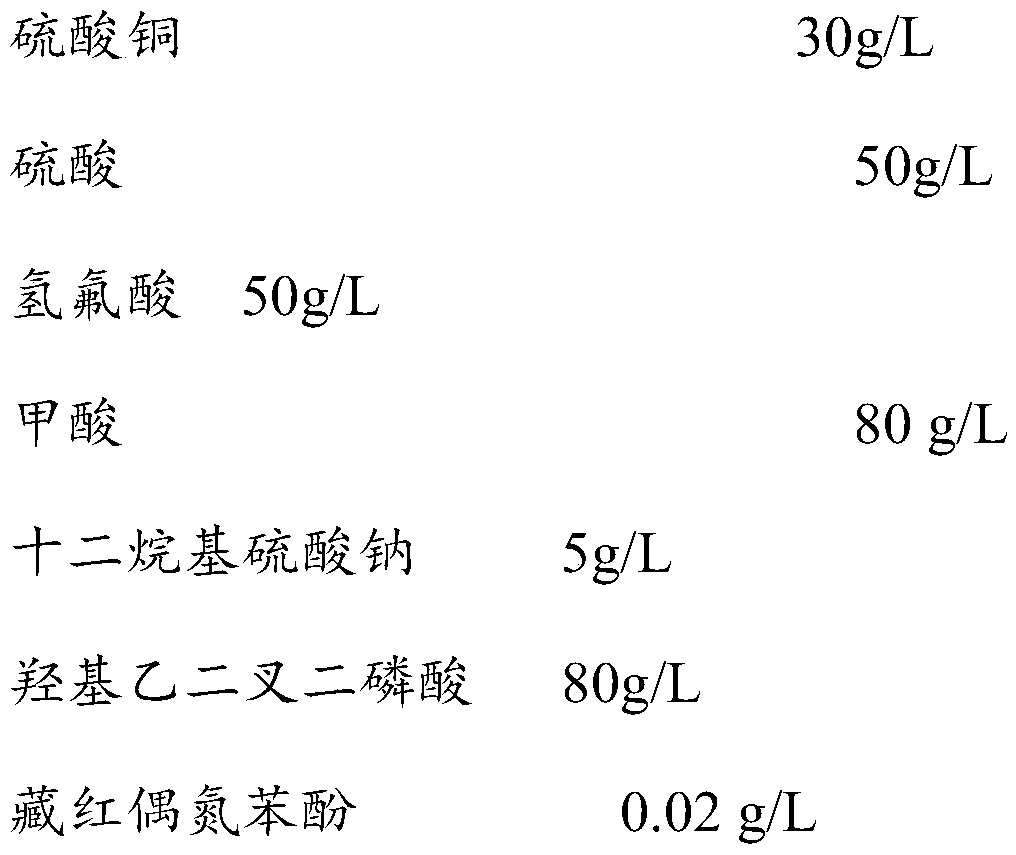

[0032] The copper plating solution that prepares comprises:

[0033]

[0034] After degreasing, pickling, and activation treatment, the stainless steel sheet is placed in the electroplating tank, put the above copper plating solution into the electroplating tank, set the current density to 1A / dm2, and electroplate at room temperature for 10 minutes to complete the stainless steel sheet. Copper plating. After observation, it was found that the copper coating after electroplating is fine and bright, and th...

Embodiment 2

[0036] This embodiment discloses a cyanide-free copper plating solution and a preparation method thereof. During preparation, take 1 / 2 of the required amount of pure water, add copper sulfate to it and stir to dissolve, then add sulfuric acid to it under constant stirring, and then respectively Add complexing agent and additives in turn and stir evenly, add the remaining pure water to the required volume to obtain copper plating solution, and then perform electroplating.

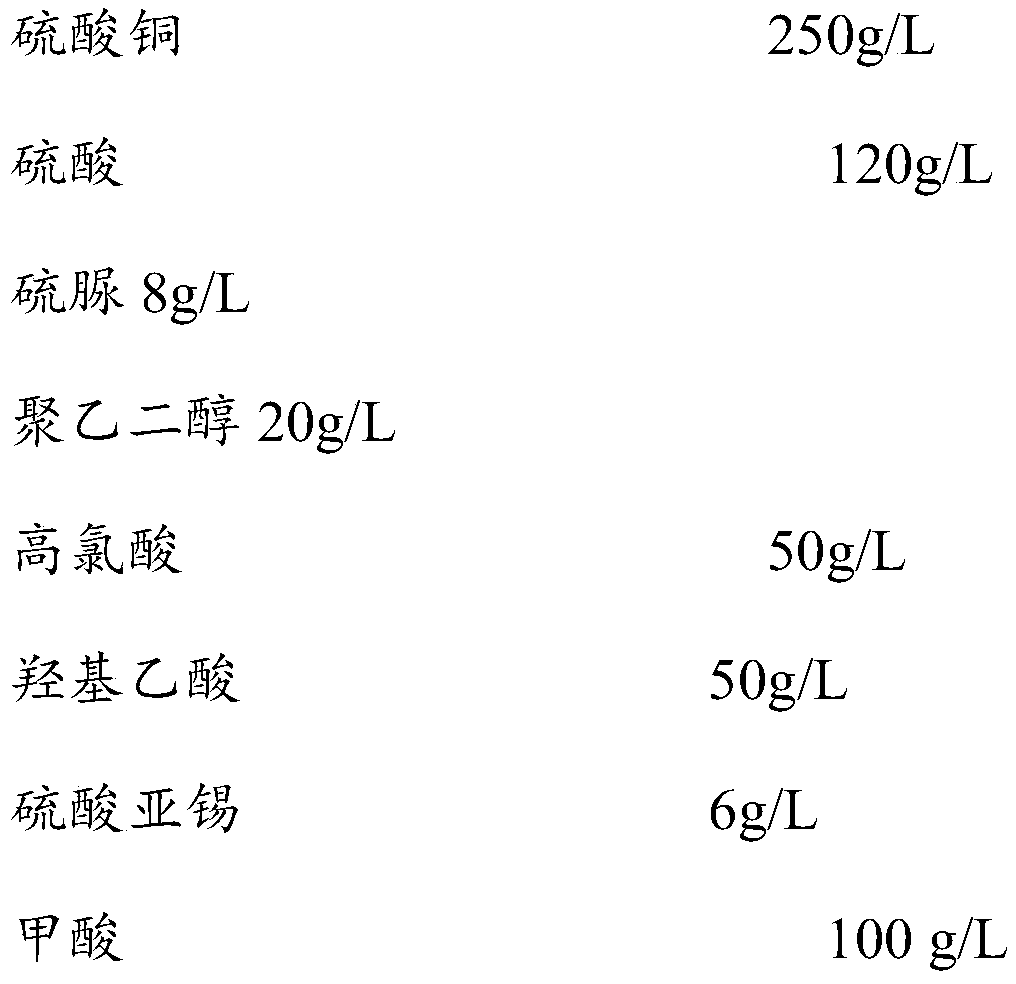

[0037] The copper plating solution that prepares comprises:

[0038]

[0039] After degreasing, pickling, and activation treatment, the stainless steel sheet is placed in the electroplating tank, put the above copper plating solution into the electroplating tank, set the current density to 10A / dm2, and electroplate at room temperature for 10 minutes to complete the stainless steel sheet. Copper plating. After observation, it was found that the copper coating after electroplating is fine and bright, and t...

Embodiment 3

[0041] This embodiment discloses a cyanide-free copper plating solution and a preparation method thereof. During preparation, take 1 / 2 of the required amount of pure water, add copper sulfate to it and stir to dissolve, then add sulfuric acid to it under constant stirring, and then respectively Add complexing agent and additives in turn and stir evenly, add the remaining pure water to the required volume to obtain copper plating solution, and then perform electroplating.

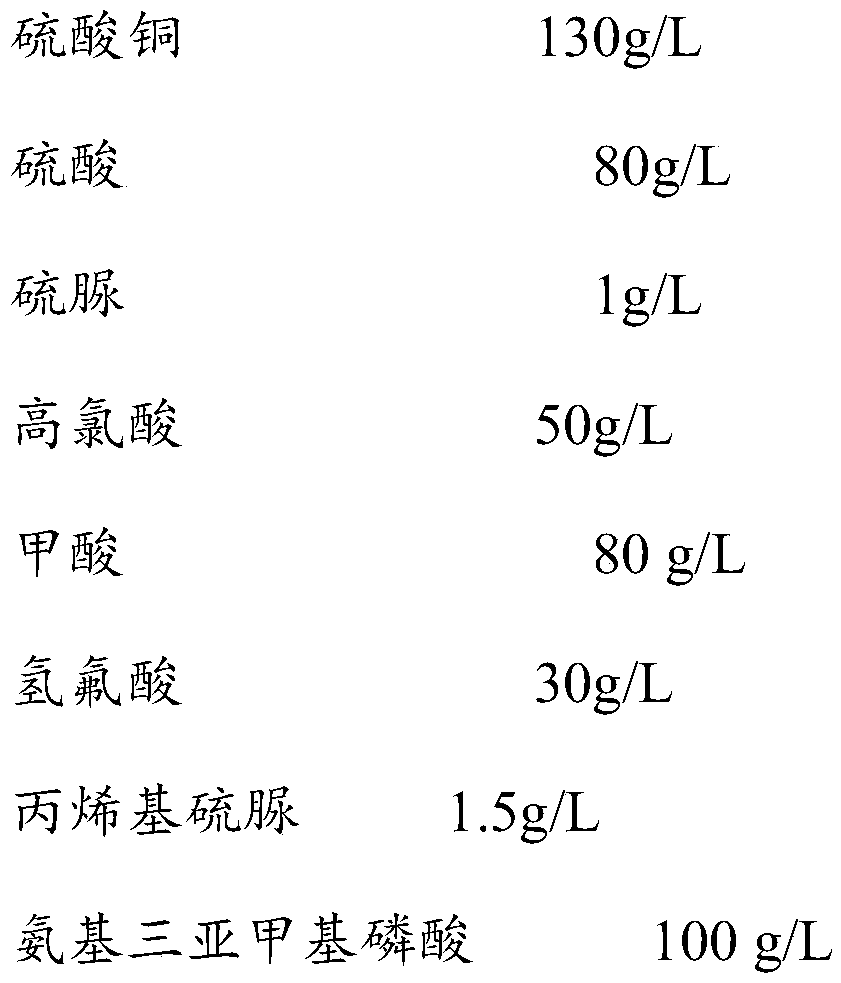

[0042] The copper plating solution that prepares comprises:

[0043]

[0044] The stainless steel sheet is degreased, pickled, and activated in sequence, and then placed in the electroplating tank. Put the above copper plating solution into the electroplating tank, set the current density to 5A / dm2, and electroplate at room temperature for 10 minutes to complete the stainless steel sheet. Copper plating. After observation, it was found that the copper coating after electroplating is fine and bright, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com