Crawler type continuous stir-frying machine for tartary buckwheat tea

A frying machine and tartary buckwheat tea technology, which is applied in the direction of tea substitutes and the like, can solve the problems that the functional components of tartary buckwheat tea have a great influence, the tartary buckwheat grains are difficult to keep consistent, and the tartary buckwheat grains are burnt and blackened. Low cost, uniform and rapid heating effect, consistent effect of particle micro-expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

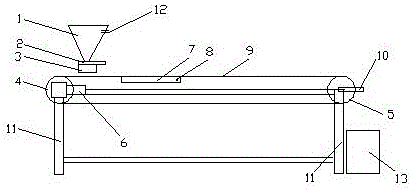

[0014] Such as figure 1 As shown, the crawler-type tartary buckwheat tea continuous frying machine of the present invention includes a feeder hopper 1, a feeder flat groove 2, an electromagnetic vibrator 3, a driving roller 4, a driven roller 5, and a speed regulating motor 6 , Electric heating plate 7, temperature sensor 8, mesh belt 9, mesh belt tensioning mechanism 10, bracket 11, material level sensor 12, and material receiver 13. The feeder hopper 1 is provided with a material level sensor 12, the feeder hopper 1 is provided with a feeder flat tank 2, and the bottom of the feeder flat tank 2 is provided with an electromagnetic vibrator 3. The supporting mesh belt 9 is supported by the driving roller 4 and the driven roller 5, the driving roller 4 and the driven roller 5 are supported by the bracket 11, the driving roller 4 is driven by the speed regulating motor 6, and the driven roller A mesh belt tensioning mechanism 10 is provided between the wheel 5 and the support 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com