Combustion catalyst for low-heat value coal

A combustion catalyst and catalyst technology, applied in the fuel, solid fuel, petroleum industry and other directions, can solve the problems of difficult to promote the combustion process of mixed coal, low decomposition temperature of strong oxidants, unstable combustion process, etc., and achieve large-scale production. , the effect of reducing land occupation and reducing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In weight percentage, the Ca 3 co 4 o 9 70%, Fe 3 o 4 25%, K 2 O 5% is ground and mixed, and crosses 100 mesh sieves to make the main active ingredient, and then gets the aforementioned main active ingredient 80% and sodium humate 20% to grind and mix, and crosses 100 mesh sieves to obtain the catalyst.

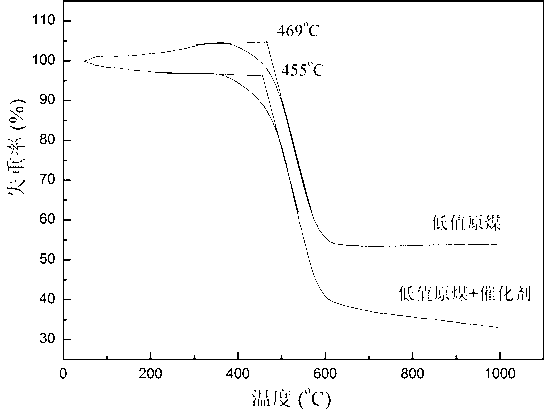

[0037] The low-value raw coal from Suntuan Coal Mine of Huainan Mining Group was naturally air-dried, ground, and passed through a 100-mesh sieve. Take 10g of coal sample, add 0.1g of catalyst powder according to 1% of the coal amount, grind and mix. The mixture sample was placed in a corundum crucible, and thermogravimetric analysis was carried out in an air atmosphere on a synchronous thermal analyzer (NETZSCH STA 409 PC). The results are compared in figure 1 .

[0038] Depend on figure 1 It can be seen that the upper line is the combustion curve of low-value raw coal, and the lower line is the combustion curve after adding the catalyst of the present i...

Embodiment 2

[0041] In weight percentage, the Ca 3 co 4 o 9 80%, Fe 3 o 4 15%, CeO 25% was ground and mixed, and passed through a 100 mesh sieve to make the main active ingredient, and then 70% of the previously prepared main active ingredient was ground and mixed with 30% potassium fulvic acid, and passed through a 100 mesh sieve to obtain the catalyst.

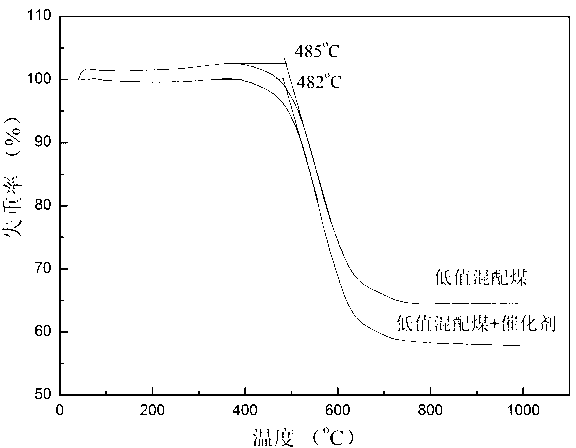

[0042] The washed medium coal, coal slime and coal gangue from a coal washing and preparation plant of Huainan Mining Group were naturally air-dried, ground, and passed through a 100-mesh sieve. According to the weight ratio, the washed medium coal, coal slime and coal gangue were mixed in a ratio of 4:3:3 respectively, and the mixed coal samples were obtained by using the heap cone quartering method. Take 10 g of coal sample, add 0.2 g of catalyst powder according to 2% of the coal amount, grind and mix. The mixture sample was placed in a corundum crucible, and thermogravimetric analysis was carried out in an air atmosphere ...

Embodiment 3

[0045] In weight percentage, the Ca 3 co 4 o 9 60%, CeO 2 20%, K 2 O 20%, grind and mix, and pass through a 100-mesh sieve to obtain a catalyst.

[0046] Sun Tuan low-value raw coal from Huainan Mining Group was naturally air-dried, ground, and passed through a 100-mesh sieve. Take 10 g of coal sample, add 0.15 g of catalyst powder according to 1.5% of the coal amount, grind and mix. The mixture sample was placed in a corundum crucible, and thermogravimetric analysis was carried out in an air atmosphere on a synchronous thermal analyzer (NETZSCH STA 409 PC), and carried out in an automatic calorimeter (ZDHW-6) according to the national standard GB / T213-2003 method Cartridge heat measurement. The results show that after adding the catalyst, the light-off temperature of low-value raw coal decreases by 12 ℃, and the low-value calorific value increases by 3.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com