Compression joint type power battery assembly structure, assembling method and electric vehicle

A power battery and assembly structure technology, applied in the field of electric vehicles, can solve the problems of being unsuitable for automated production, low connection reliability, and low assembly efficiency, and achieve the effects of facilitating automated production, high assembly efficiency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

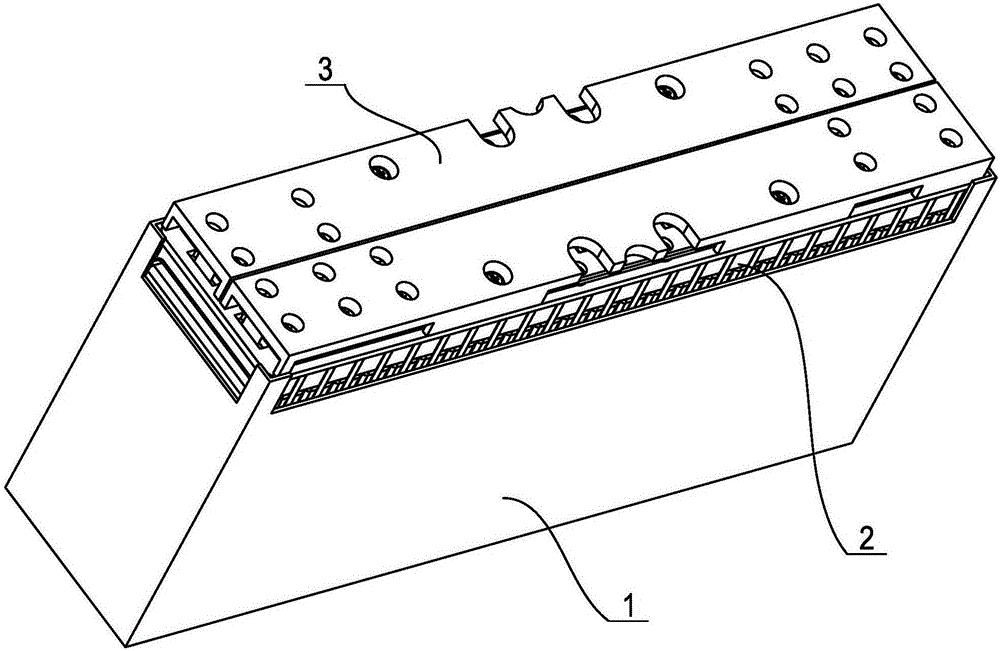

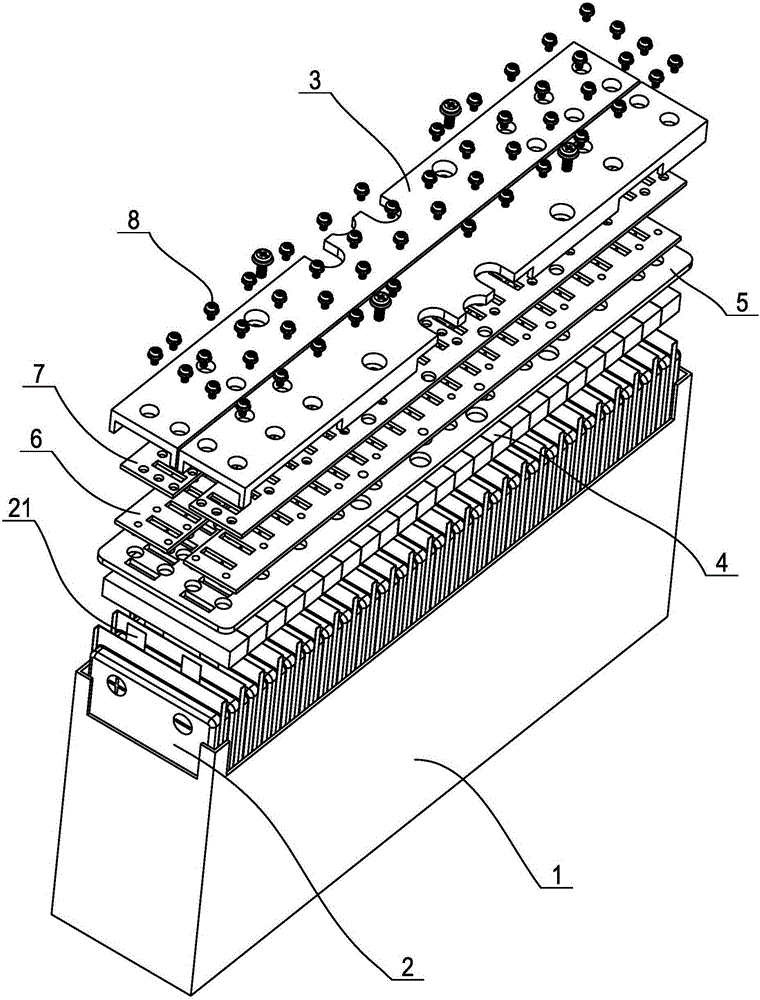

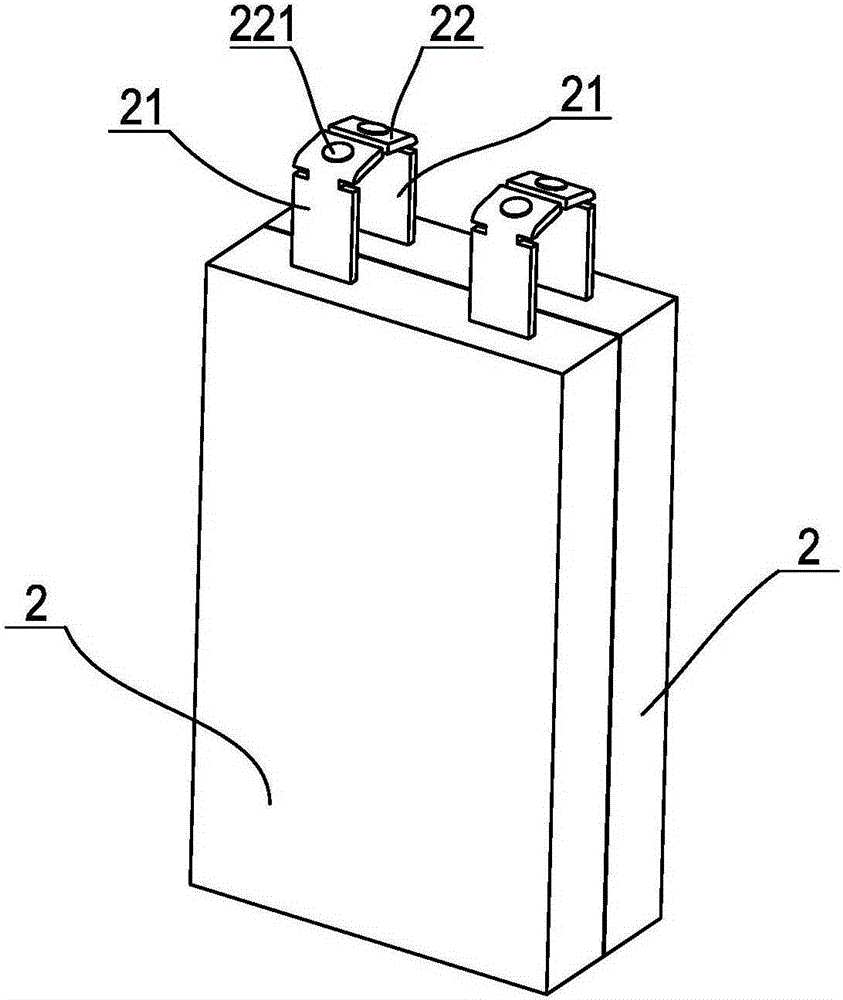

[0039] Embodiment 1: as figure 1 , figure 2 As shown, a crimping type power battery assembly structure includes a cube-shaped battery compartment 1 with an upper opening, several soft-packed cells 2 arranged side by side in the battery compartment along the length direction of the battery compartment, and the soft-packed cells The tabs 21 are arranged on the upper side of the soft pack cell, and the tabs are composed of sheet-shaped positive tabs and negative tabs, and the positive and negative tabs of all the soft pack cells are arranged in the same direction, thus forming a Positive tabs formed from positive tabs and negative tabs formed from negative tabs. Such as image 3 As shown, the upper parts of the positive tab and the negative tab in the tab are bent to form a crimping portion 22, so that the positive tab and the negative tab are roughly L-shaped.

[0040] In addition, we need to arrange a shock-absorbing plate 4 made of foam on the upper side of the pouch cell ...

Embodiment 2

[0044] Embodiment 2: A crimping type power battery assembly method, comprising the following steps:

[0045] a. If figure 1 As shown, bend the sheet-shaped tabs on the flat soft-packed battery cell to 95-100 degrees to form a crimping part, and then figure 1 , figure 2As shown, put an even number of soft-packed cells one by one into the vertically spaced separation grooves in the rectangular battery compartment with the upper opening. The separation grooves are arranged along the length of the battery compartment. At this time, the crimping part is 5 The angle of -10 degrees is inclined upwards, the positive tabs of all the tabs of the soft-packed cells are arranged into a positive tab string, and the negative tabs of all the tabs of the soft-packed cells are arranged into a negative tab string, and the odd-numbered The pouch cell and the subsequent adjacent even-numbered pouch cells form a pouch cell pair, that is to say, the first and second pouch cells form a pouch cell ...

Embodiment 3

[0050] Embodiment 3: An electric vehicle includes a power battery. Specifically, the power battery is composed of several power battery modules connected in series, and the power battery module adopts the crimping type power battery assembly structure described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com