Magnetic passive element and manufacturing method thereof

A technology of magnetic passive components and manufacturing methods, applied in magnetic core manufacturing, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of high cost, decreased inductance value, and high cost of human resources, and achieve outstanding effects and manufacturing costs. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0039] The magnetic passive element of the present invention is mainly aimed at a magnetic passive element with a large number of coil turns, or a magnetic passive element with a large inductance. The application range of the magnetic passive component is also relatively wide. It can be used not only on the PCB board, but also in high-frequency signal transmission technology or low-frequency power supply, inductors, and transformers.

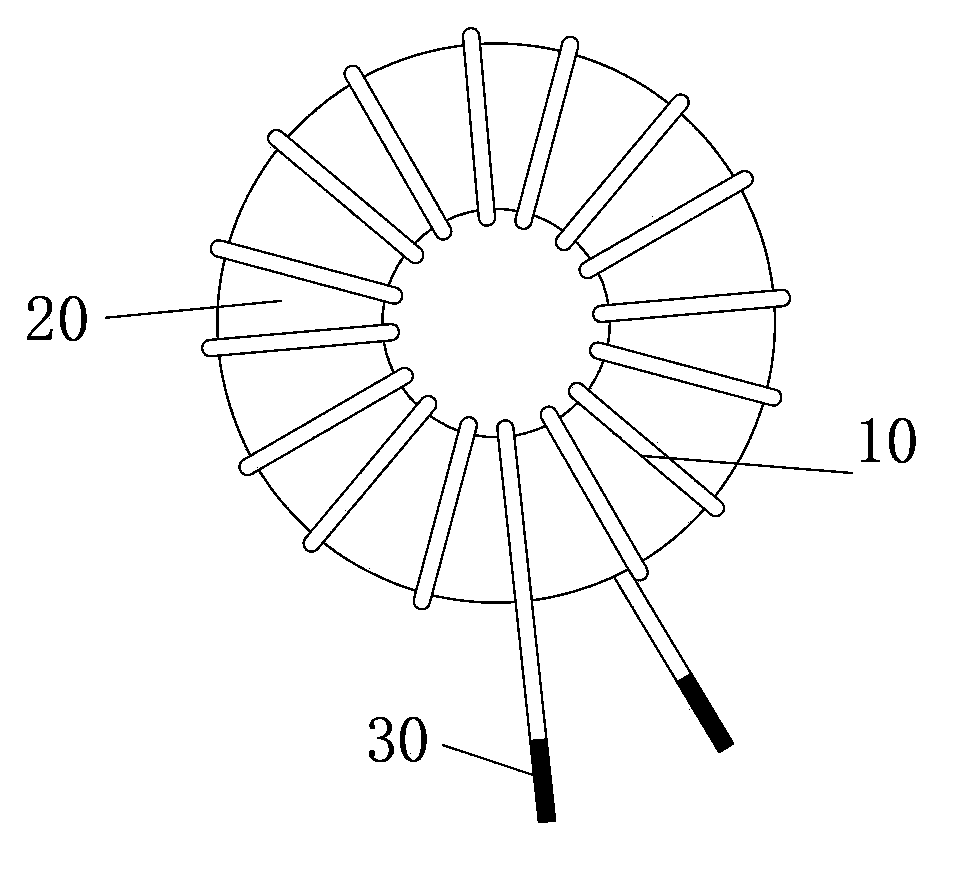

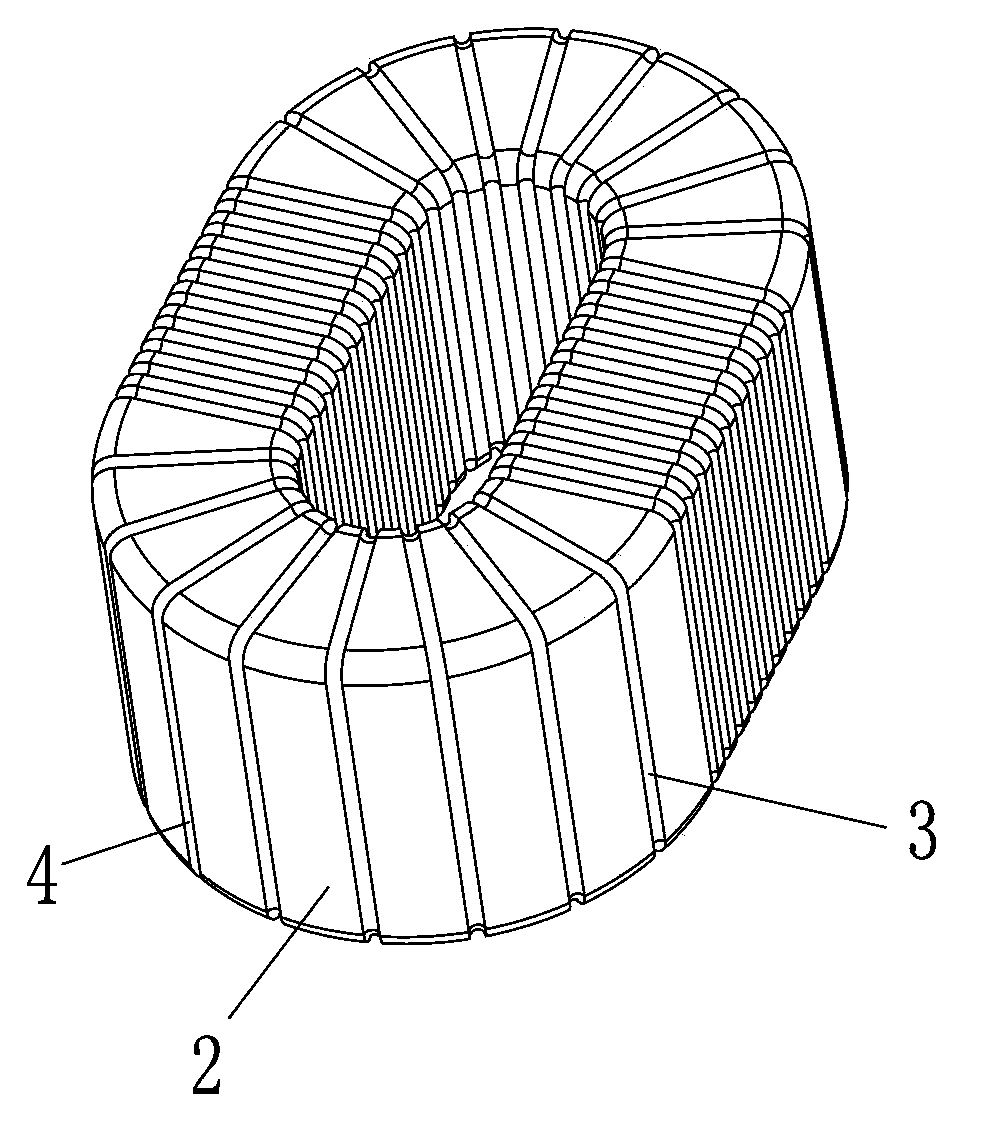

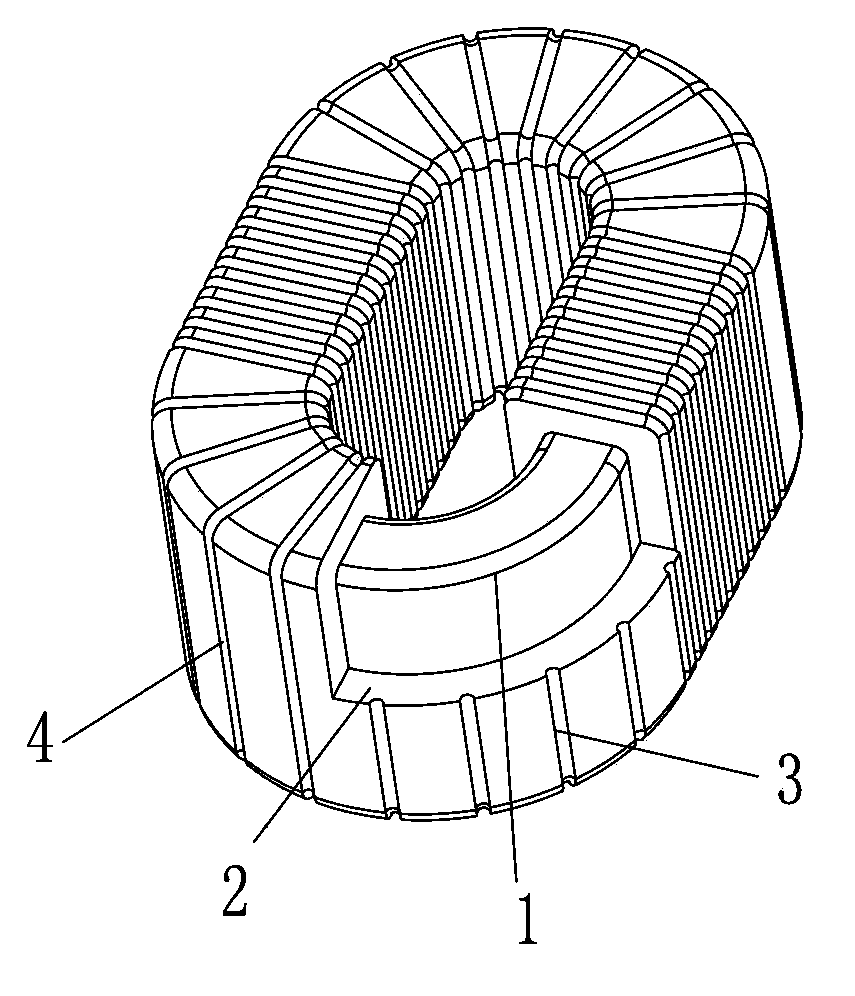

[0040] see Figure 2A ~ Figure 2B , Figure 2A It is a structural schematic diagram of an embodiment of the magnetic passive element of the present invention, Figure 2B for Figure 2A cutaway view. In this embodiment, the magnetic passive element of the present invention includes a magnetic core 1, an insulating layer 2 covering the magnetic core 1, and a metal wire layer 4 deposited on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com