Keyboard adopting plastic-injection baseboard and production method of keyboard

A technology of plastic injection molding and keyboard, applied in the input/output of user/computer interaction, key modules, and input/output process of data processing, etc. problems, to improve the accuracy and efficiency of automated assembly, ensure product quality, and reduce production costs

Inactive Publication Date: 2011-06-29

江海波

View PDF3 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

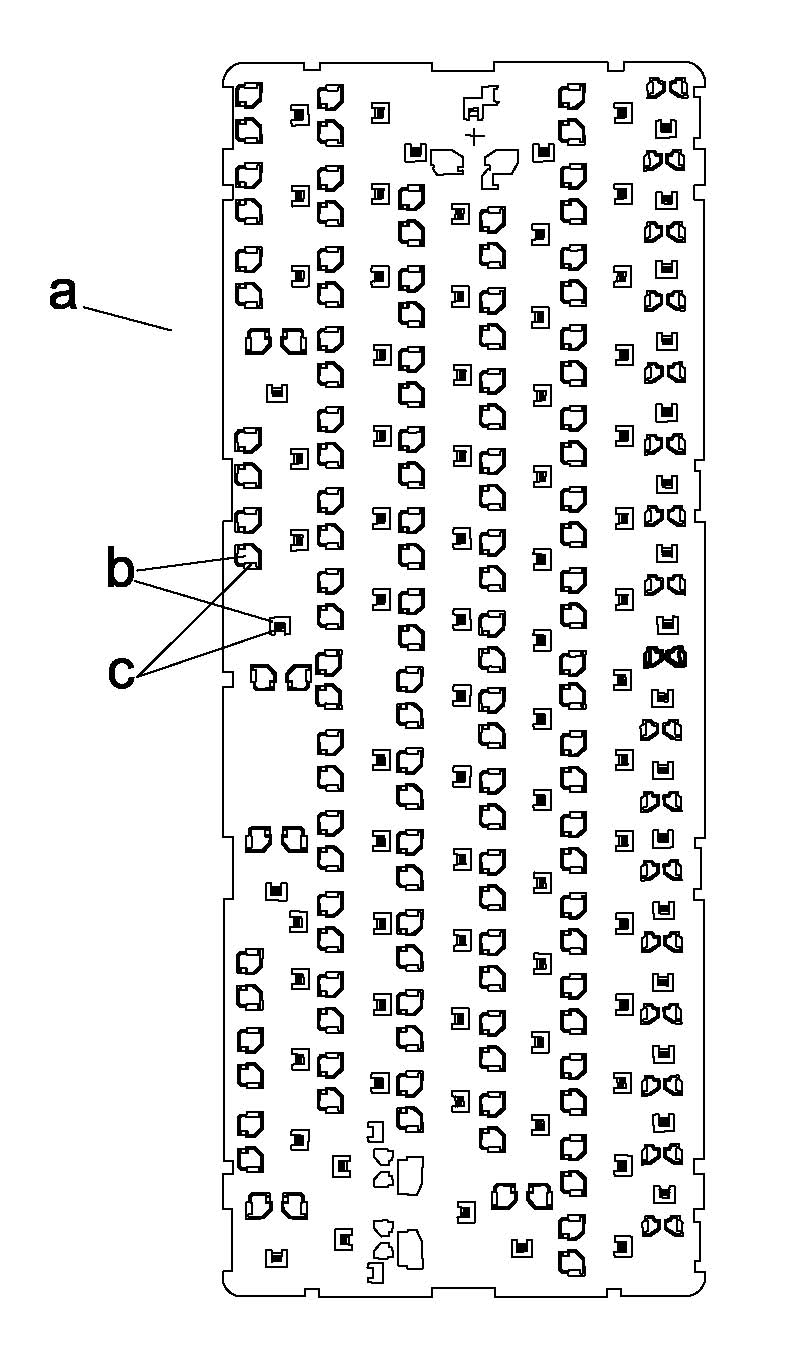

No matter be the application of notebook computer or desktop computer all be unable to do without computer keyboard, existing notebook keyboard and some desktop computers such as the light and thin type keyboard that Apple computer adopts, its structure mostly adopts the keycap that several slices are distributed at intervals, and keycap One-to-one correspondence of several scissor feet and several elastic silicon gels, several lower pin holders corresponding to the lower pins of several scissor feet, keyboard bottom plate and printed circuit film covering the surface of the keyboard bottom plate are assembled. As shown in Figure 1, holes b are directly punched on the aluminum plate a and a number of fixing hooks c are formed to form the lower pin fixing seat. The accuracy of the hook is poor, it is difficult to realize automatic production in assembly, the cost of manual operation is high, and automatic assembly cannot be realized

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

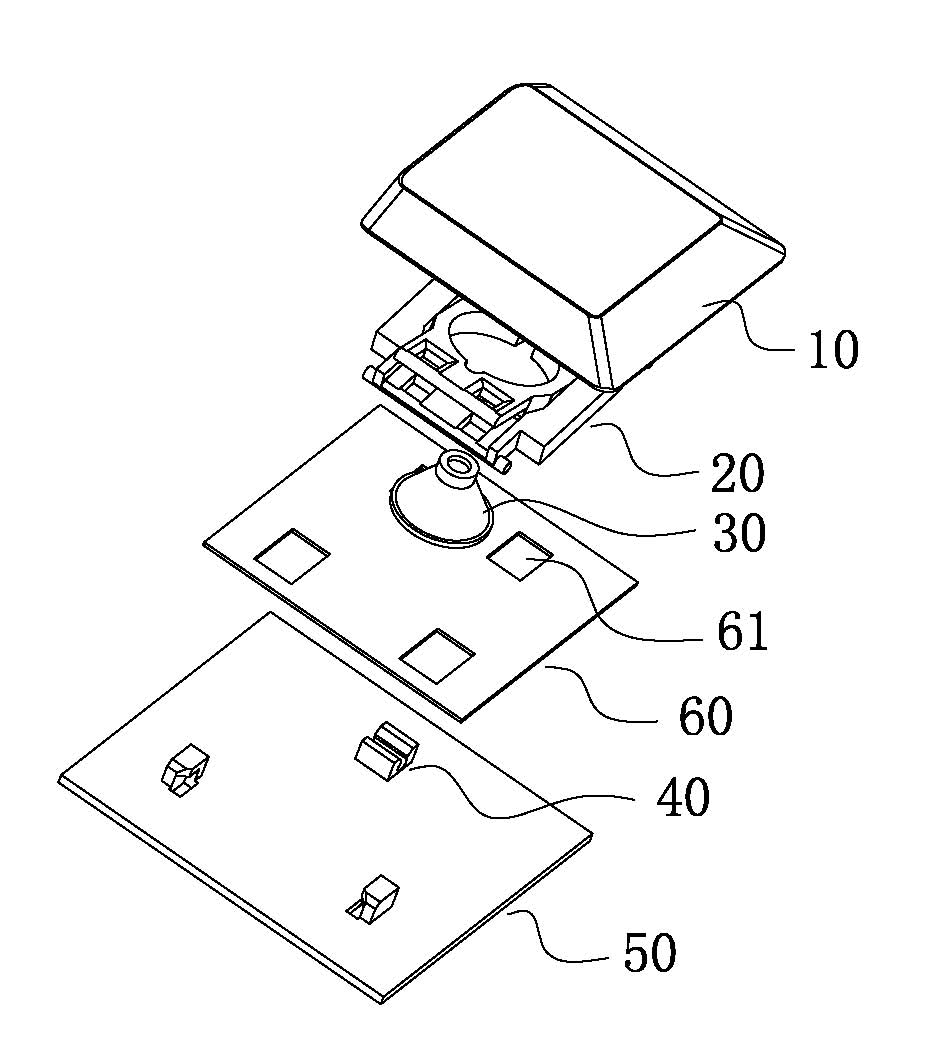

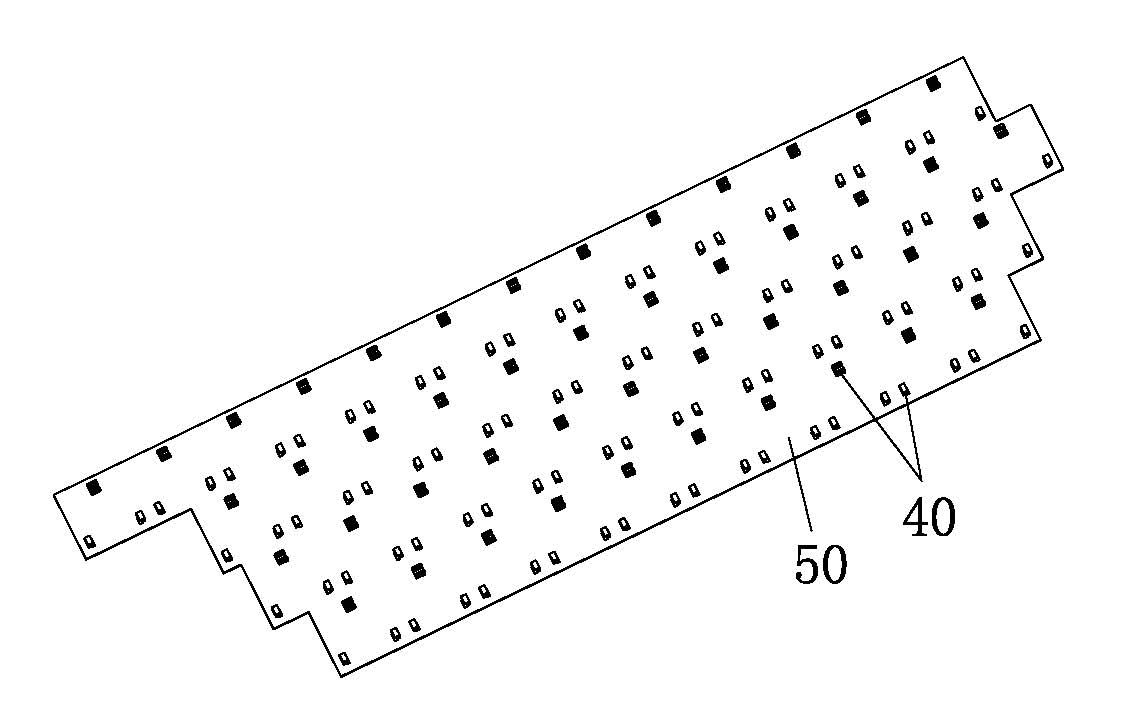

The invention relates to a keyboard adopting plastic-injection baseboard and a production method of the keyboard, and the keyboard is used for laps or desktop computers. The keyboard comprises a plurality of button caps arranged at interval, scissor legs, a plurality of elastic colloidal silica, a plurality of lower pin fixing seats, a keyboard baseboard and a printed circuit film covered on the surface of the keyboard baseboard, wherein the bottom surface of the button cap is provided with upper pin fixing seats; after the components are assembled, the upper pins of the scissor legs are spliced and fixed on the upper pin fixing seats; the lower pins of the scissor legs are spliced and fixed on the lower pin fixing seats; the top of the elastic colloidal silica is propped against the bottom surface of the button cap; the bottom of the elastic colloidal silica is positioned on the button switch of the printed circuit film; and each lower pin fixing seat and the keyboard baseboard are the same plastic piece injected and shaped once by a plastic material. According to the invention, the production process is simplified, production cost is lowered, assembling accuracy and automated assembling efficiency are improved, product quality is guaranteed, and the invention is suitable for automated production.

Description

A keyboard using a plastic injection molding bottom plate and its production method technical field The invention relates to the technical field of computer keyboards, in particular to a keyboard using a plastic injection molding bottom plate for a notebook computer or a desktop computer and a production method thereof. Background technique With the development of the information industry, computers have been increasingly widely used. No matter be the application of notebook computer or desktop computer all be unable to do without computer keyboard, existing notebook keyboard and some desktop computers such as the light and thin type keyboard that Apple computer adopts, its structure mostly adopts the keycap that several slices are distributed at intervals, and keycap One-to-one correspondence of several scissor feet and several elastic silicon gels, several lower pin holders corresponding to the lower pins of several scissor feet, keyboard bottom plate and printed circuit...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01H13/705H01H3/12G06F3/02

CPCH01H2227/022G06F3/0202H01H2233/03H01H2229/044H01H13/88H01H3/125

Inventor 江海波

Owner 江海波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com