Power battery module, assembling method and electric vehicle

A power battery and module technology, which is applied to battery components, batteries, circuits, etc., can solve the problems of unsuitability for automated production, low connection reliability, and low assembly efficiency, and achieve the convenience of automated production, high assembly efficiency, and The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

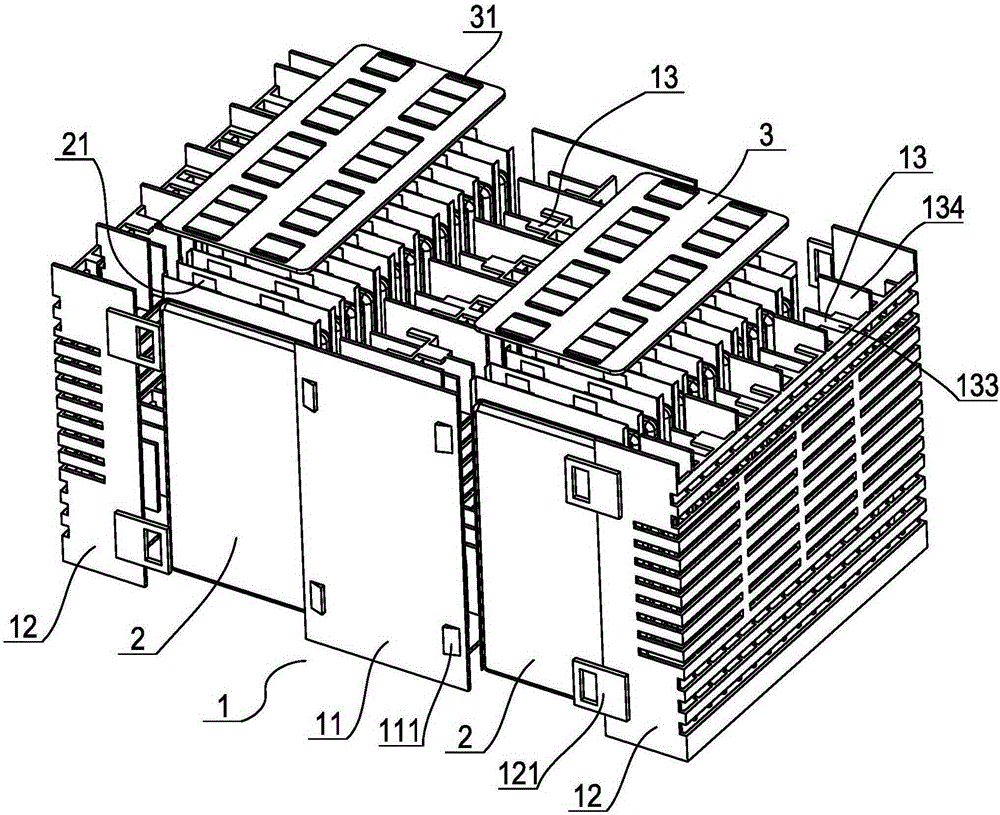

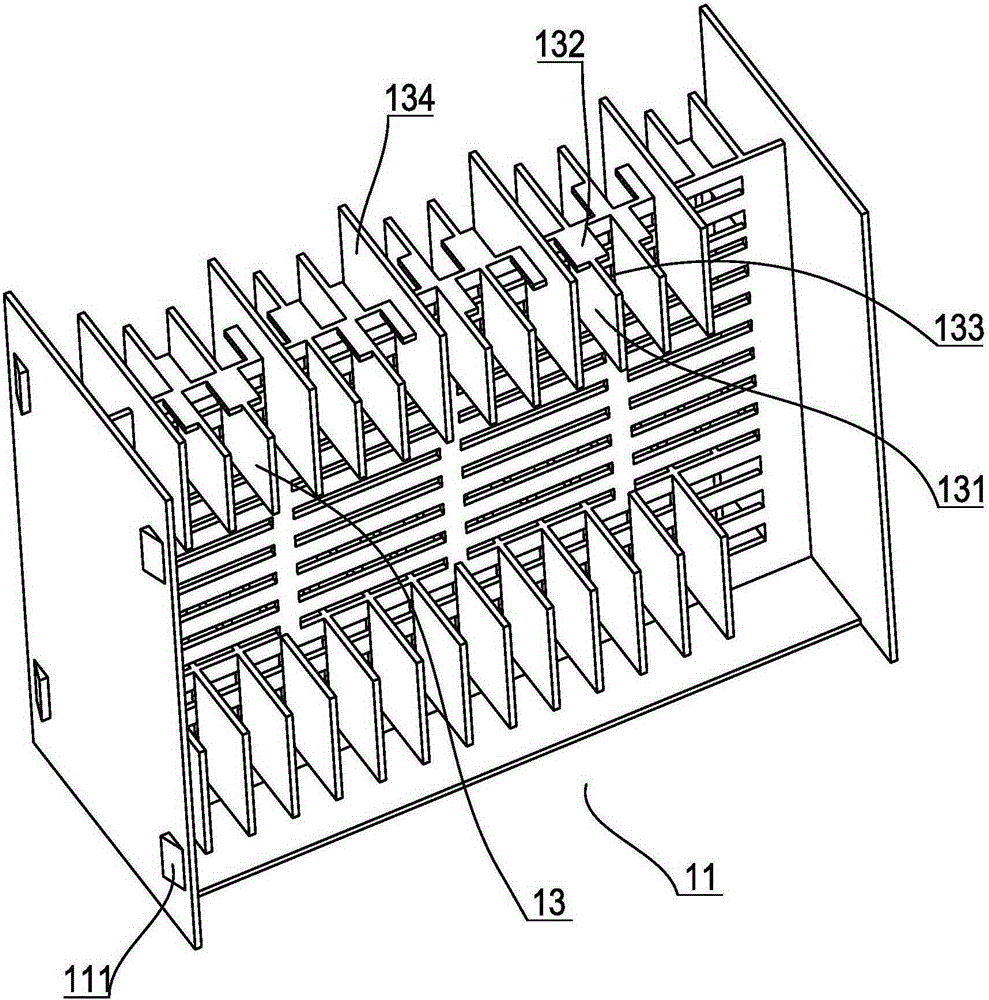

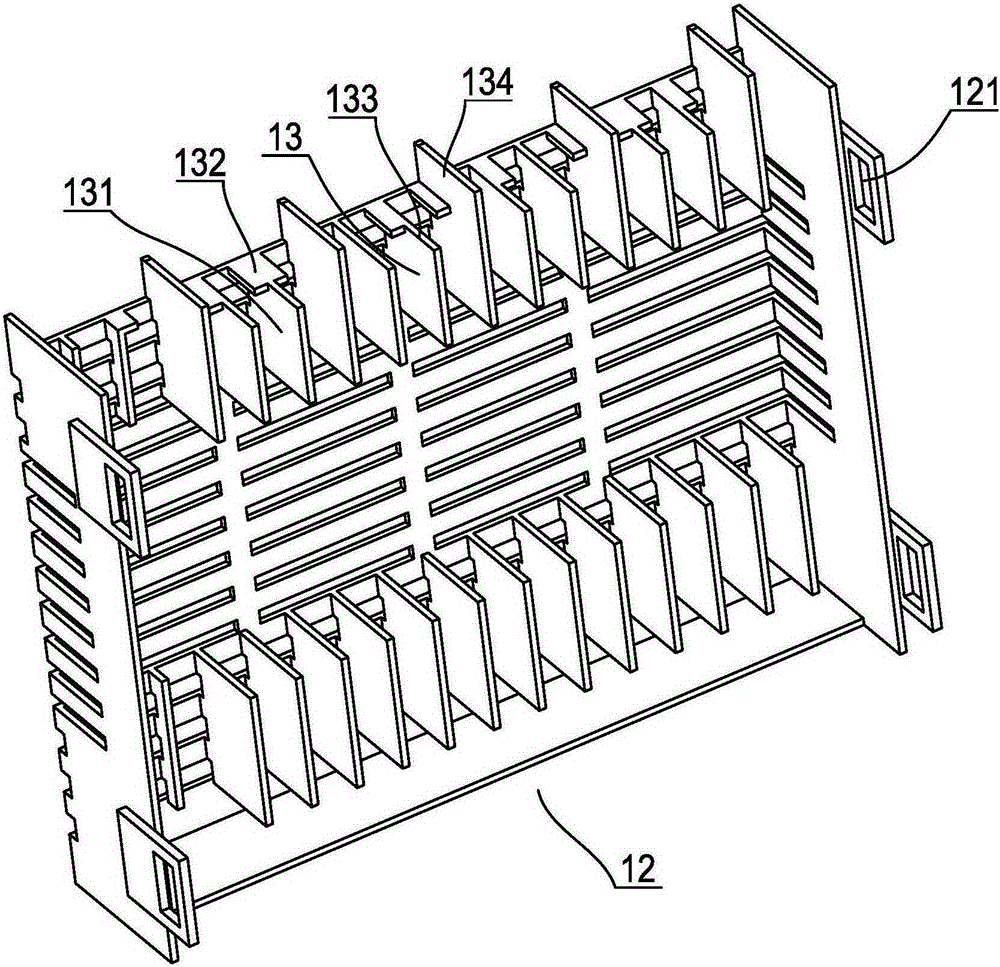

[0041] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, a power battery module includes a battery compartment 1, a number of soft-pack batteries 2 arranged in the battery compartment, and a PCB board 3 arranged on the upper part of the battery compartment. The upper side of the soft-pack batteries is provided with sheet-like The tab 21 formed by the positive tab and the negative tab. The battery compartment adopts a splicing structure, which includes the main fixing bracket 11 in the middle and the splicing brackets 12 respectively clamped on the left and right sides of the main fixing bracket. The cavities on the left and right sides of the battery compartment are respectively provided with a number of equal distances along the longitudinal direction of the battery compartment. The lug separators 13 on the splicing bracket are also provided with several lug separators, and the tab separators on each side of the main fixing bracket correspond to the tab separators ...

Embodiment 2

[0047] Embodiment 2: A method for assembling a power battery module, wherein the structure of the power battery module is as described in Embodiment 1, specifically including the following steps:

[0048] a. Put an even number of soft-packed cells vertically into the left and right sides of the main fixing bracket of the battery compartment. Arranged into a negative ear string, the odd-numbered soft-packed cells and the subsequent even-numbered soft-packed cells form a soft-packed cell pair, that is, the first and second soft-packed cells form a soft pack Cell pair, the 3rd and 4th soft-packed cells form a soft-packed cell pair...and so on, and then the two splicing brackets are respectively clamped on the left and right sides of the main fixing bracket, so that each soft-packed battery The cores are sequentially clamped in the cell card slot formed by the splicing of the main fixing bracket and the splicing bracket;

[0049] b. Place horizontal PCB boards on the upper parts ...

Embodiment 3

[0053] Embodiment 3: An electric vehicle includes a power battery. Specifically, the power battery is composed of several power battery modules connected in series, wherein the power battery module adopts the power battery module described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com