Method for preparing glabridin

A technology of licorice and licorice, applied in the field of preparation of licorice, can solve the problems of low efficiency, long column chromatography elution period and the like, and achieves controllable process parameters, large preparation amount and short production cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

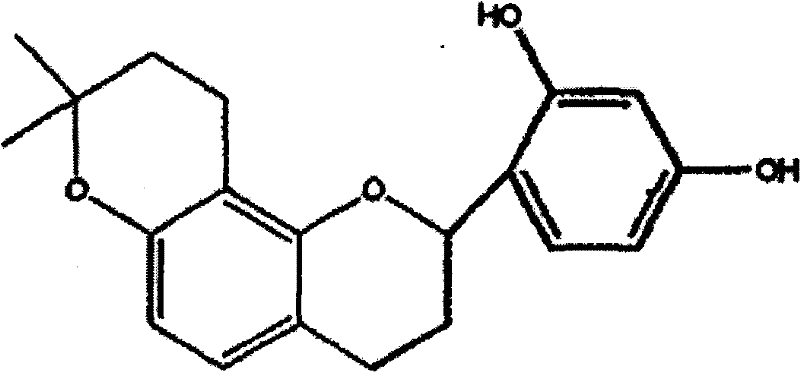

Image

Examples

Embodiment 1

[0020] Take Glycyrrhiza glabra, take 1kg, put it into a microwave extraction tank, add 8 times the amount of 80% ethanol for microwave extraction for 60 minutes, filter the liquid, add 6 times the amount of 80% ethanol solution for microwave extraction for 30 minutes, combine the extracts twice and concentrate under reduced pressure Alcohol-free, take 1% sodium hydroxide solution to adjust the concentrated solution to be neutral, transfer it to a separatory funnel, add an equal volume of ethyl acetate to extract 3 times, and extract the extract with 5% sodium bicarbonate solution for 2 times, and concentrate the organic phase , Add 50g of polyamide and dry to obtain a sample. Take chloroform, methanol, and aqueous solution in a mixing ratio of 7:5:3, remove the phase as an entrainer, crush the sample and add it to the extraction kettle, adjust the parameter pressure to 12MPa, extract the temperature to 40°C, and feed liquid CO 2 Fluid, after reaching the above parameters, CO ...

Embodiment 2

[0022] Take Glycyrrhizae glabra and crush it, take 1kg, put it into a microwave extraction tank, add 6 times the amount of 70% ethanol for microwave extraction for 40 minutes, extract 3 times, combine the 2 extractions, concentrate under reduced pressure and alcohol-free, take 0.5% sodium hydroxide solution to adjust the concentrated solution Neutral, transfer to a separatory funnel, add an equal volume of ethyl acetate to extract 4 times, the extract is back extracted 3 times with 5% sodium bicarbonate solution, the organic phase is concentrated, and 80g of polyamide is added to dry to obtain a sample. Take chloroform, methanol, and aqueous solution in a mixing ratio of 8:5:3, remove the phase as an entrainer, crush the sample and add it to the extraction kettle, adjust the parameter pressure to 16MPa, extract the temperature at 30°C, and feed liquid CO 2 Fluid, after reaching the above parameters, CO 2 The flow rate was controlled at 120ml / min, the entrainer flow rate was 2m...

Embodiment 3

[0024] Take Glycyrrhizae glabra and crush it, take 5kg, put it into a microwave extraction tank, add 6 times the amount of 70% ethanol for microwave extraction for 40 minutes, extract 3 times, combine the 2 extractions, concentrate under reduced pressure and alcohol-free, take 0.2% sodium hydroxide solution to adjust the concentrated solution Neutrality, transferred to a separatory funnel, added 2 times the volume of ethyl acetate to extract 3 times, the extract was back-extracted 2 times with 5% sodium bicarbonate solution, the organic phase was concentrated, the organic phase was concentrated, and 400g of polyamide was added to dry to obtain sample. Take chloroform, methanol, and aqueous solution in a mixing ratio of 8:6:3, remove the phase as an entrainer, crush the sample and add it to the extraction kettle, adjust the parameter pressure to 14MPa, extract the temperature at 35°C, and feed liquid CO 2 Fluid, after reaching the above parameters, CO 2 The flow rate was contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com