Pipe fitting feed device and working method thereof

A technology for pipe fittings and material forks, which is applied in the field of pipe fitting feeding devices, can solve the problems of high labor intensity and easy clamping of workers, and achieve the effect of high efficiency, safety and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

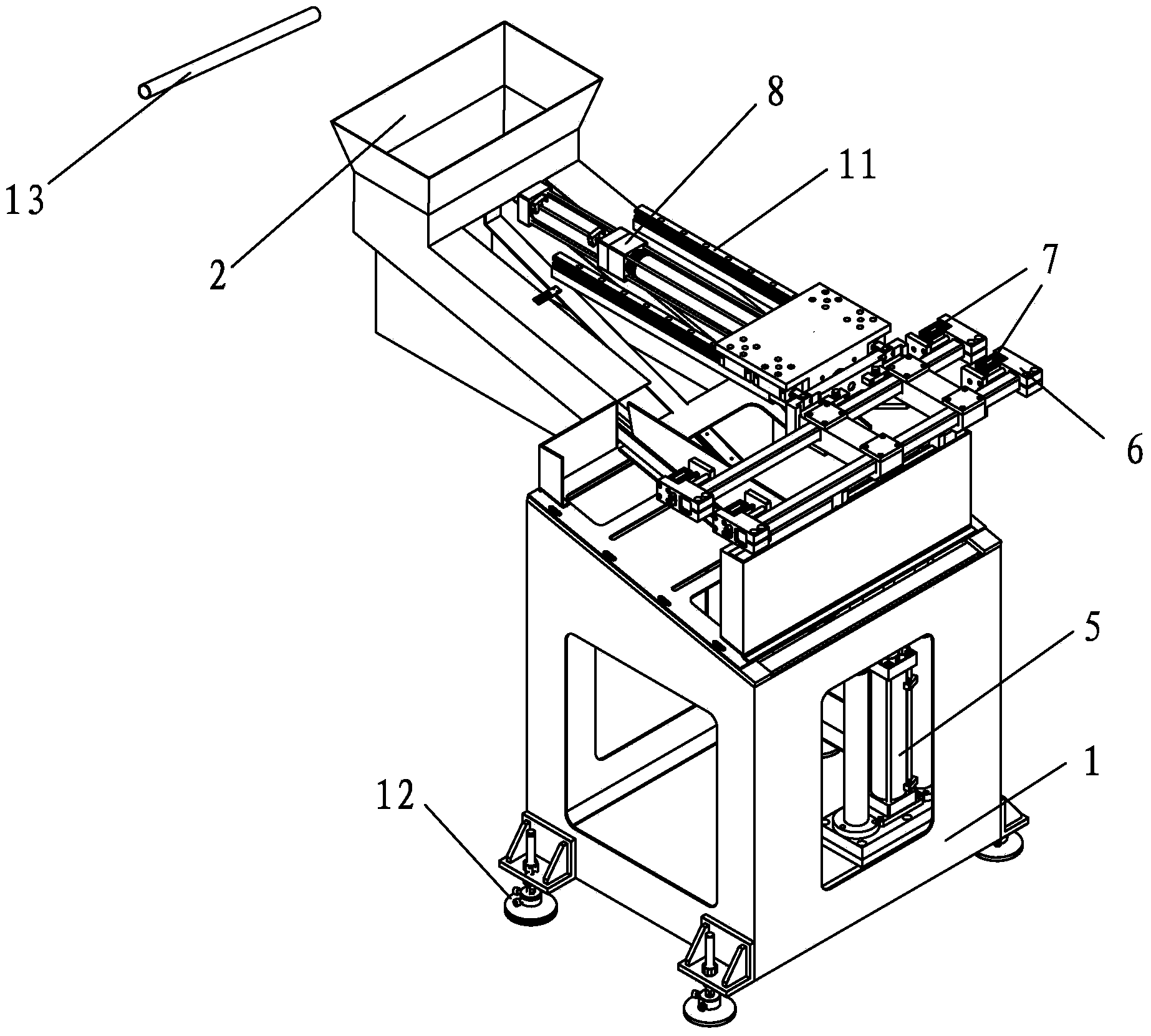

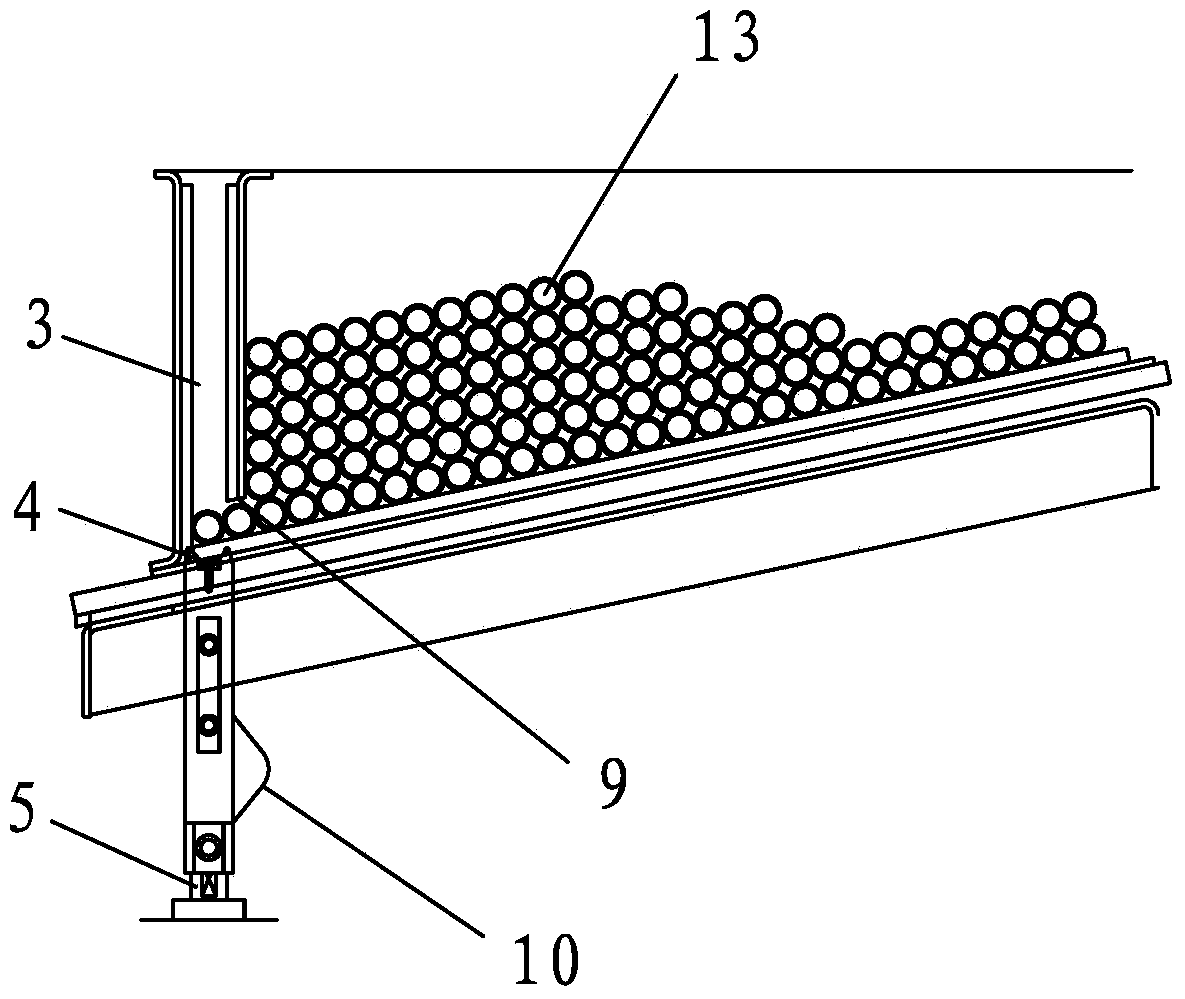

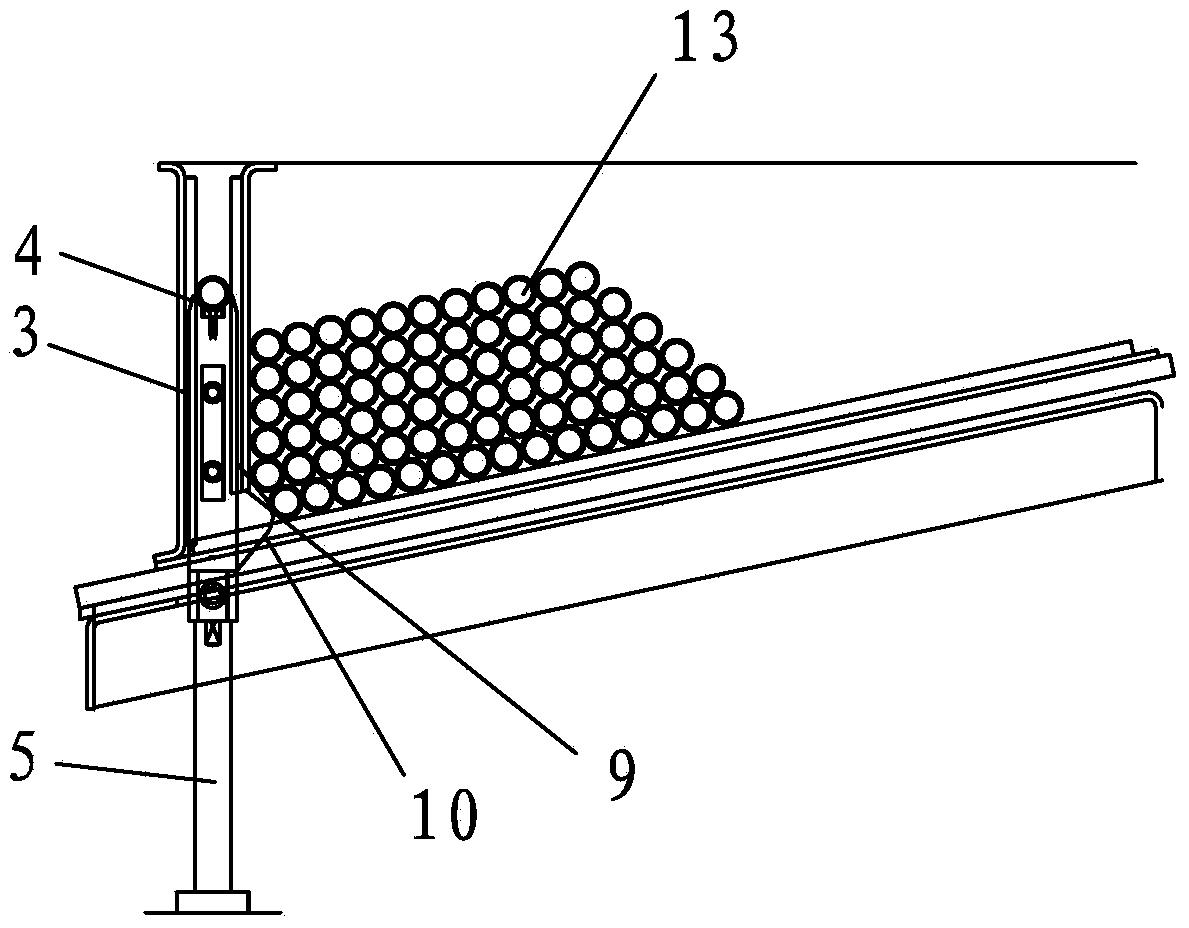

[0026] Embodiment one: see attached Figure 1-3 As shown, a pipe fitting feeding device includes a frame 1, a feed bin 2 arranged on the frame 1, a conveying slope arranged on the upper part of the frame 1 facing the lower outlet of the feed bin 2, and vertically arranged on the machine The lifting track 3 on the frame 1, the lifting fork 4 that can slide up and down on the lifting track 3, the lifting cylinder 5 that is set on the frame 1 for controlling the movement of the lifting fork 4, and the lifting fork 4 that is arranged on the frame 1, the cylinder fixing seat 6 located above the lifting track 3, the clamping cylinder 7 arranged on the cylinder fixing seat 6 and capable of clamping the pipe fittings from both ends of the pipe fittings, and the clamping cylinder 7 arranged horizontally on the frame 1 for pushing the cylinder fixing seat The feeding cylinder 8 of 6, the lower end of the conveying slope is provided with a funnel mouth 9 that can only pass through a hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com