Equipment for automatically processing vehicle steering universal-joint fork ear punch

A universal joint fork and automatic processing technology, which is applied in metal processing equipment, drilling/drilling equipment, manufacturing tools, etc., can solve the problems of high labor intensity for operators, difficult quality control, and difficult quality assurance, and achieve saving The effects of manpower, efficiency growth, and product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

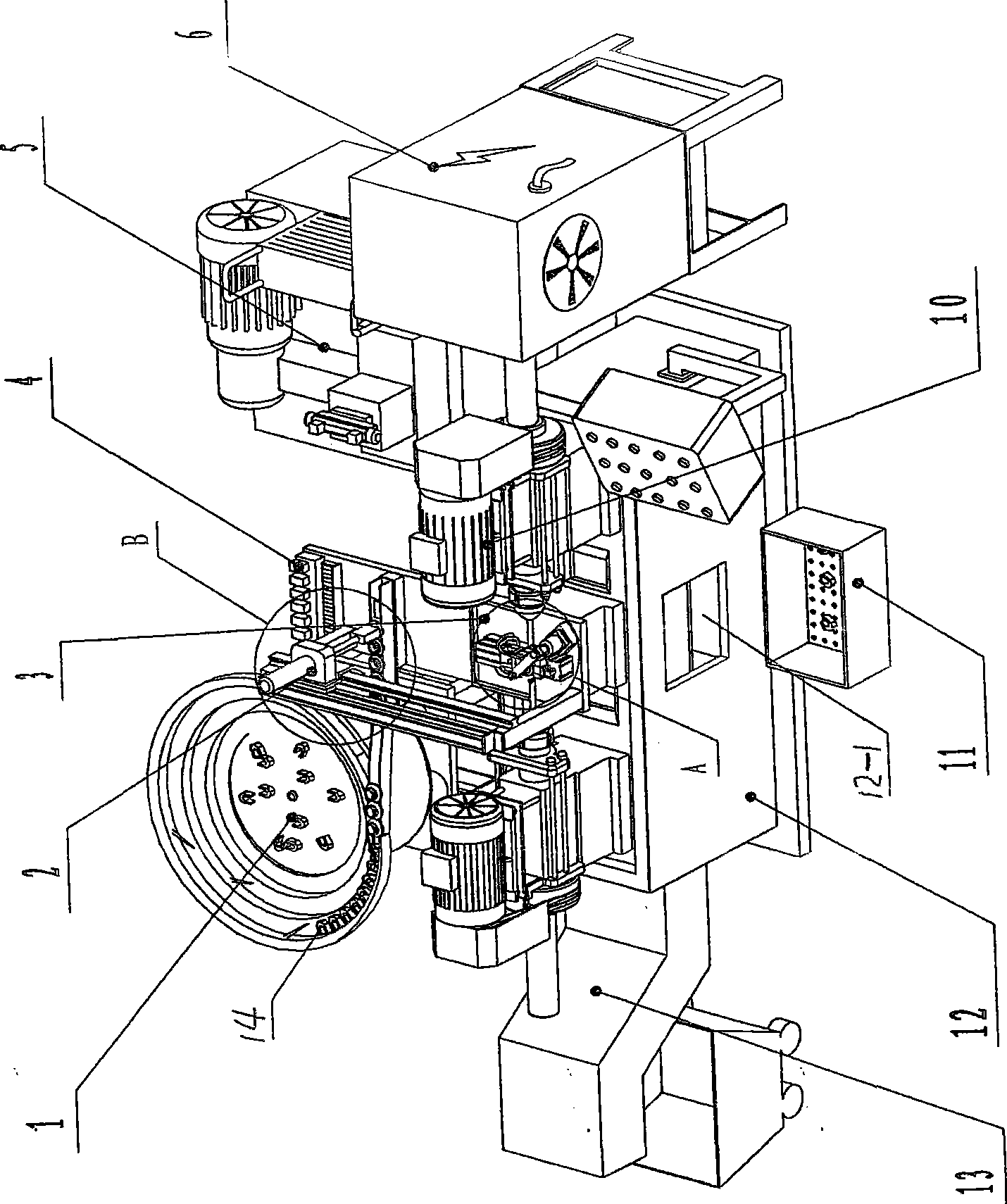

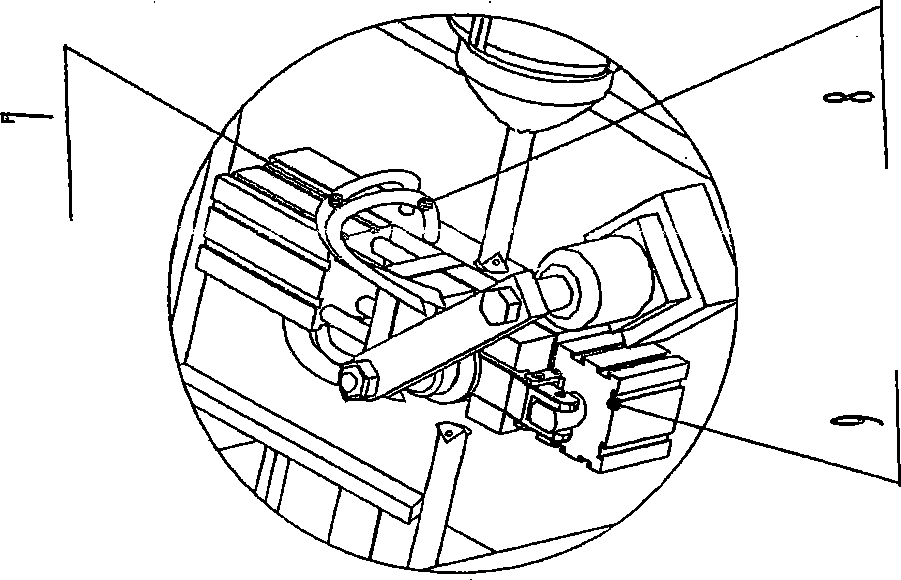

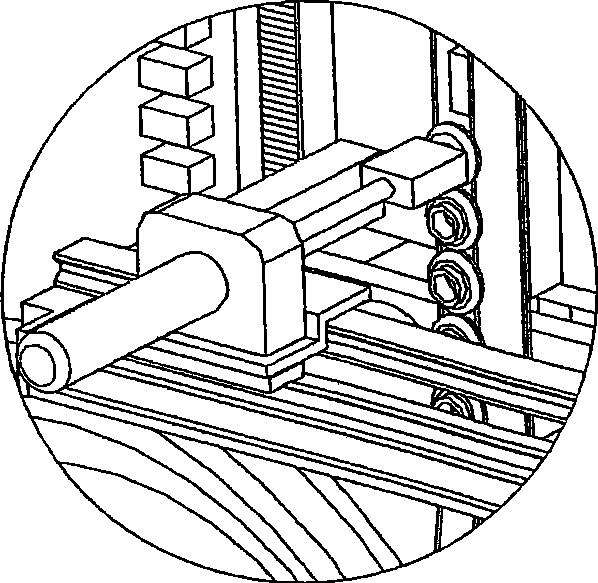

[0031] see Figure 1-7 , the automobile steering universal joint fork ear hole automatic processing equipment related to the present invention is mainly composed of a directional sorting vibrating hopper 1, a grabbing feeding device 2, a positioning clamping device 3, a pneumatic system 4, a hydraulic system 5, an electric control system 6, a cooling Device 7, chip blowing device 8, feeding device 9, hole processing device 10, material receiving box 11, machine base 12 and chip removal machine 13 are composed. The machine base 12 is the main carrier of the processing equipment, including the grabbing and feeding device 2, the positioning and clamping device 3, the pneumatic system 4, the cooling device 7, the chip blowing device 8, the feeding device 9, the hole processing device 10 and the chip removal machine 13 are installed on it. The cooling pump 7 - 1 of the cooling device 7 is placed inside the frame 12 . The inner cavity of the machine base 12 is the coolant tank. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com