Slide block demolding mechanism with function of coring twice

A technology of demolding mechanism and sliding block, applied in the field of sliding block demolding mechanism, can solve the problems of not being able to adapt to automatic production, reducing the dimensional accuracy of plastic parts, reducing the qualified rate of products, etc., achieving a simple structure and improving the dimensional accuracy of plastic parts , the effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

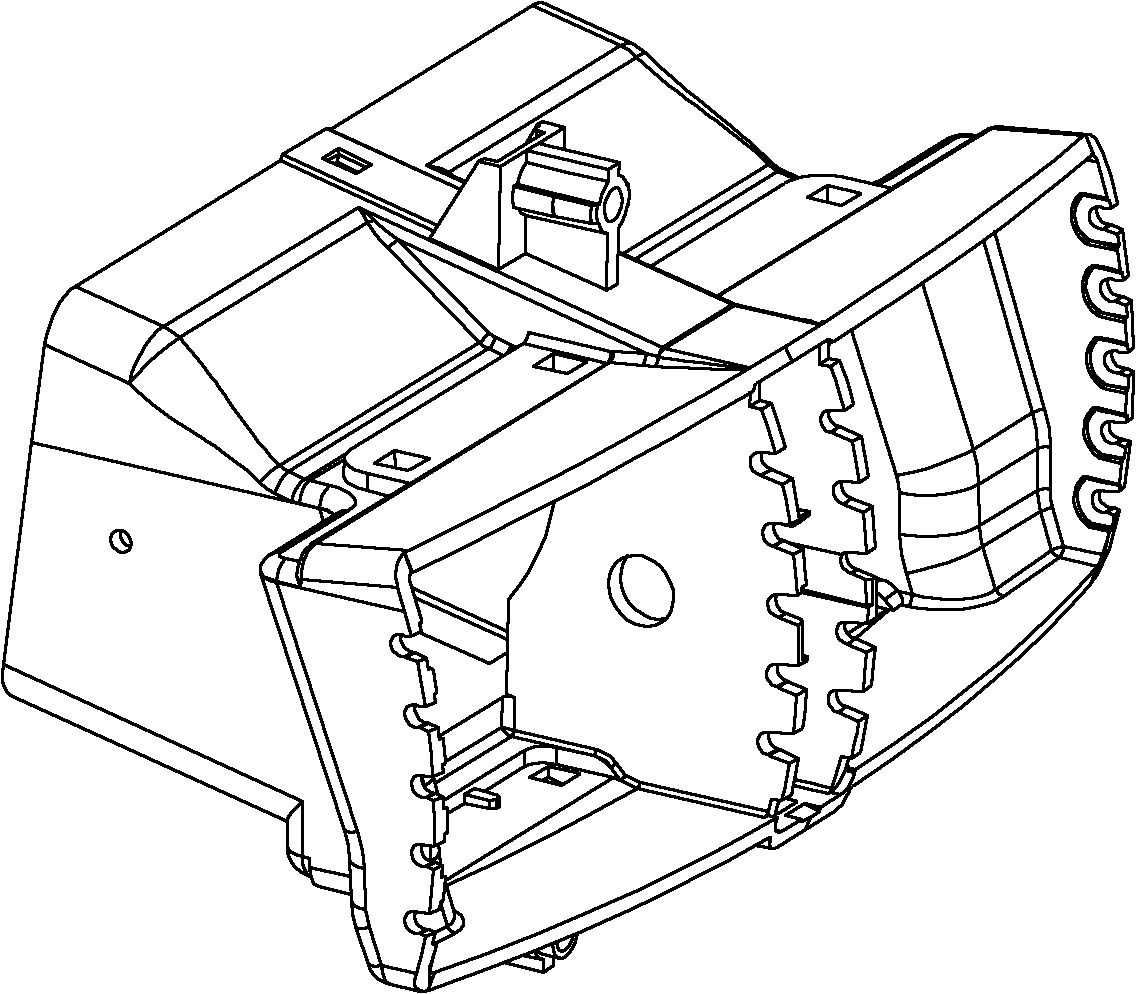

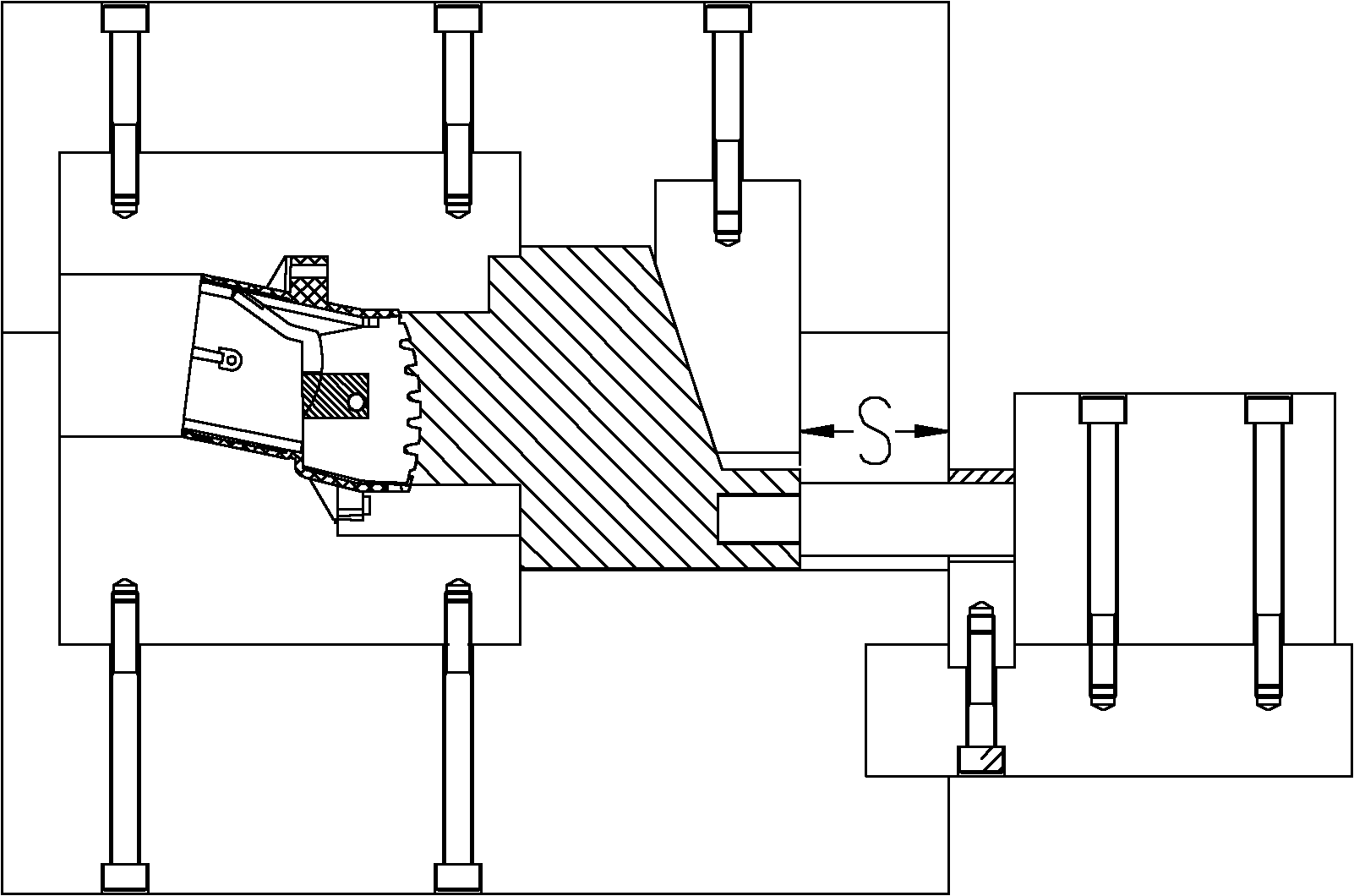

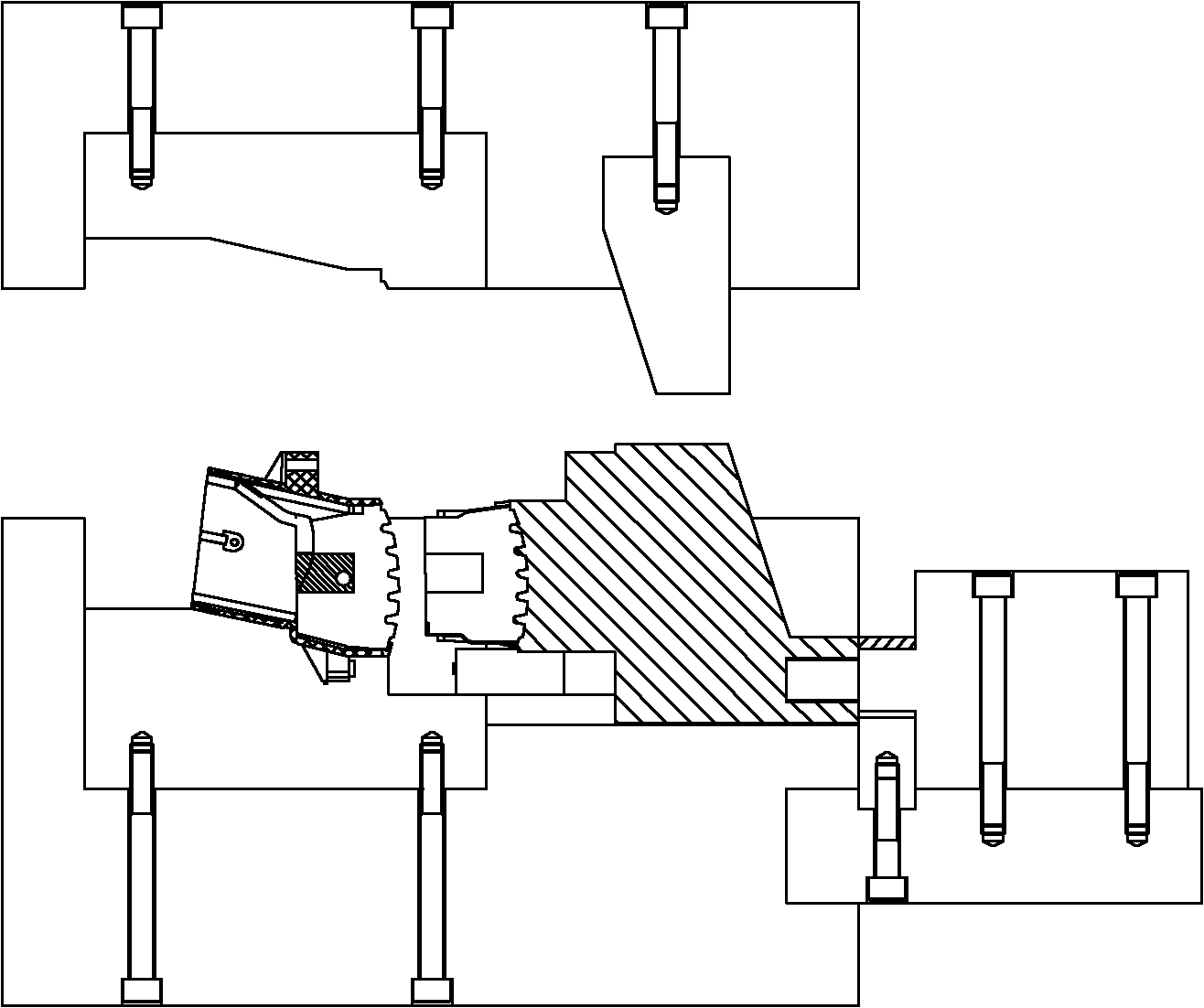

[0028] Refer to attached Figure 5-10 , to further illustrate the present invention:

[0029] The slider demoulding mechanism with two core pulls includes a fixed template 1 with a fixed mold core 11, a movable template 2 with a movable mold core 21, a slider 3 mounted on the movable template 2 that can move laterally, and a sliding The block 3 is connected, the oil cylinder 4 that drives the slider 3 away from the mold core when the mold is opened, and the locking block 5 that is fixedly connected with the fixed template 1 and presses the slider 3 to the mold core 11, 21 when the mold is closed, and A stopper 6 located between the oil cylinder 4 and the slider 3 to limit the lateral displacement of the slider;

[0030] The locking block 5 cooperates with the slider 3 through the inclined surface, and when the mold is closed, the fixed template 1, the movable template 2 and the slider 3 surround the mold cavity of the plastic part;

[0031] The slider 3 includes a main slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com