Preparation method of self-assembly silanization of pure titanium metal surface

A metal surface and silanization technology, which is applied in the coating process of metal materials, can solve the problems of low biological activity and no strong chemical combination, and achieve the effect of simple operation, easy promotion and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Material cleaning. A square sheet of pure titanium with a thickness of 0.1 mm and a purity of 99.9% was used as the substrate, ultrasonically cleaned with absolute ethanol, acetone, and deionized water for 10 min, wiped with filter paper, and air-dried for later use;

[0026] Step 2: surface acid treatment. Using HF and HNO at a volume ratio of 1:1 3 The mixed solution was polished for 5 minutes, the surface was rinsed with deionized water, and dried in a constant temperature drying oven at 50 °C for 15 minutes for later use;

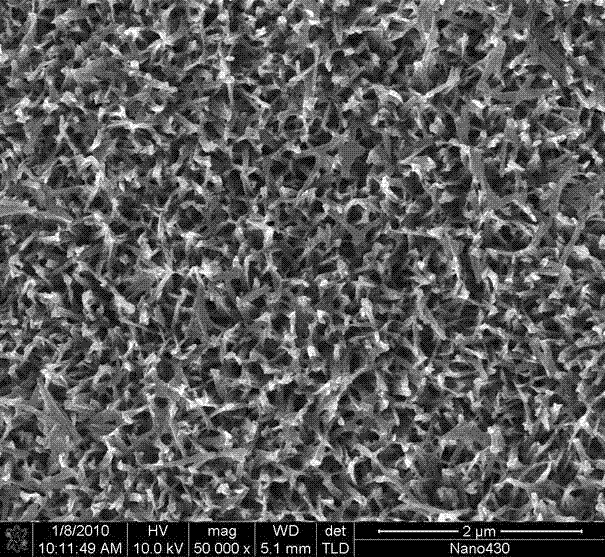

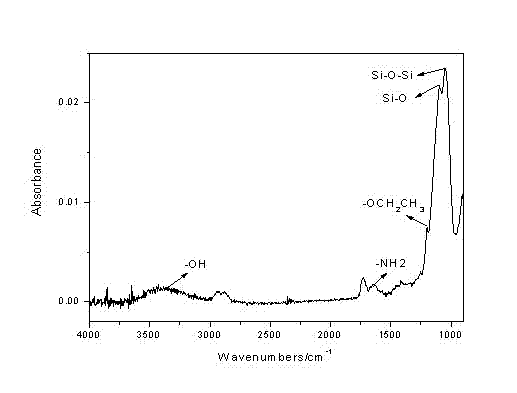

[0027] Step 3: Alkaline heat treatment. The acid-treated pure titanium was placed in a plastic bottle filled with 2 mol / L NaOH solution, the material was completely soaked in the NaOH solution, and placed in a constant temperature drying oven at 80 °C for 72 hours of alkali heat treatment, and then ultrasonicated with deionized water Clean the surface for 10 minutes, and dry it in a constant temperature drying oven at 50 °C for 15 min...

Embodiment 2

[0031] Step 1: Material cleaning. A square sheet of pure titanium with a thickness of 0.1 mm and a purity of 99.9% was used as the substrate, ultrasonically cleaned with absolute ethanol, acetone, and deionized water for 10 min, wiped with filter paper, and air-dried for later use;

[0032] Step 2: surface acid treatment. Using HF and HNO at a volume ratio of 1:1 3 The mixed solution was polished for 8 minutes, the surface was rinsed with deionized water, and dried in a constant temperature drying oven at 50 °C for 20 minutes for later use;

[0033] Step 3: Alkaline heat treatment. The acid-treated pure titanium was placed in a plastic bottle filled with 6 mol / L NaOH solution, the material was completely immersed in the NaOH solution, and placed in a constant temperature drying oven at 80 °C for 24 hours of alkali heat treatment, and then ultrasonicated with deionized water Clean the surface for 10 minutes, and dry it in a constant temperature drying oven at 50 ℃ for 20 mi...

Embodiment 3

[0036] Step 1: Material cleaning. A square sheet of pure titanium with a thickness of 0.1 mm and a purity of 99.9% was used as the substrate, ultrasonically cleaned with absolute ethanol, acetone, and deionized water for 10 min, wiped with filter paper, and air-dried for later use;

[0037] Step 2: surface acid treatment. Using HF and HNO at a volume ratio of 1:1 3 The mixed solution was polished for 10 minutes, the surface was rinsed with deionized water, and dried in a constant temperature drying oven at 50 °C for 15 minutes before use;

[0038] Step 3: Alkaline heat treatment. The acid-treated pure titanium was placed in a plastic bottle filled with 8 mol / L NaOH solution, the material was completely immersed in NaOH solution, and placed in a constant temperature drying oven at 80 °C for 48 hours of alkali heat treatment, and then ultrasonicated with deionized water Clean the surface for 10 minutes, and dry it in a constant temperature drying oven at 50 °C for 15 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com