Method for sticking metallic thin sheet to frame, and device therefor

A metal sheet and framing technology, applied in lighting devices, metal material coating process, ion implantation plating, etc., can solve the problems of deformation or relaxation of the opening, easy deformation, and inability to obtain a slit pattern, so as to prevent deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0064] The present invention can be applied to any metal thin plate that needs to be kept in a flat state without deformation or slack, but it is preferably used as a multi-faceted mask for vapor deposition (having a plurality of mask parts) for the manufacture of organic EL elements that require precision. sheet metal used for masks). Hereinafter, preferred embodiments of the present invention will be described by taking a thin metal plate used as an example of a multi-faceted mask for vapor deposition in the production of an organic EL element.

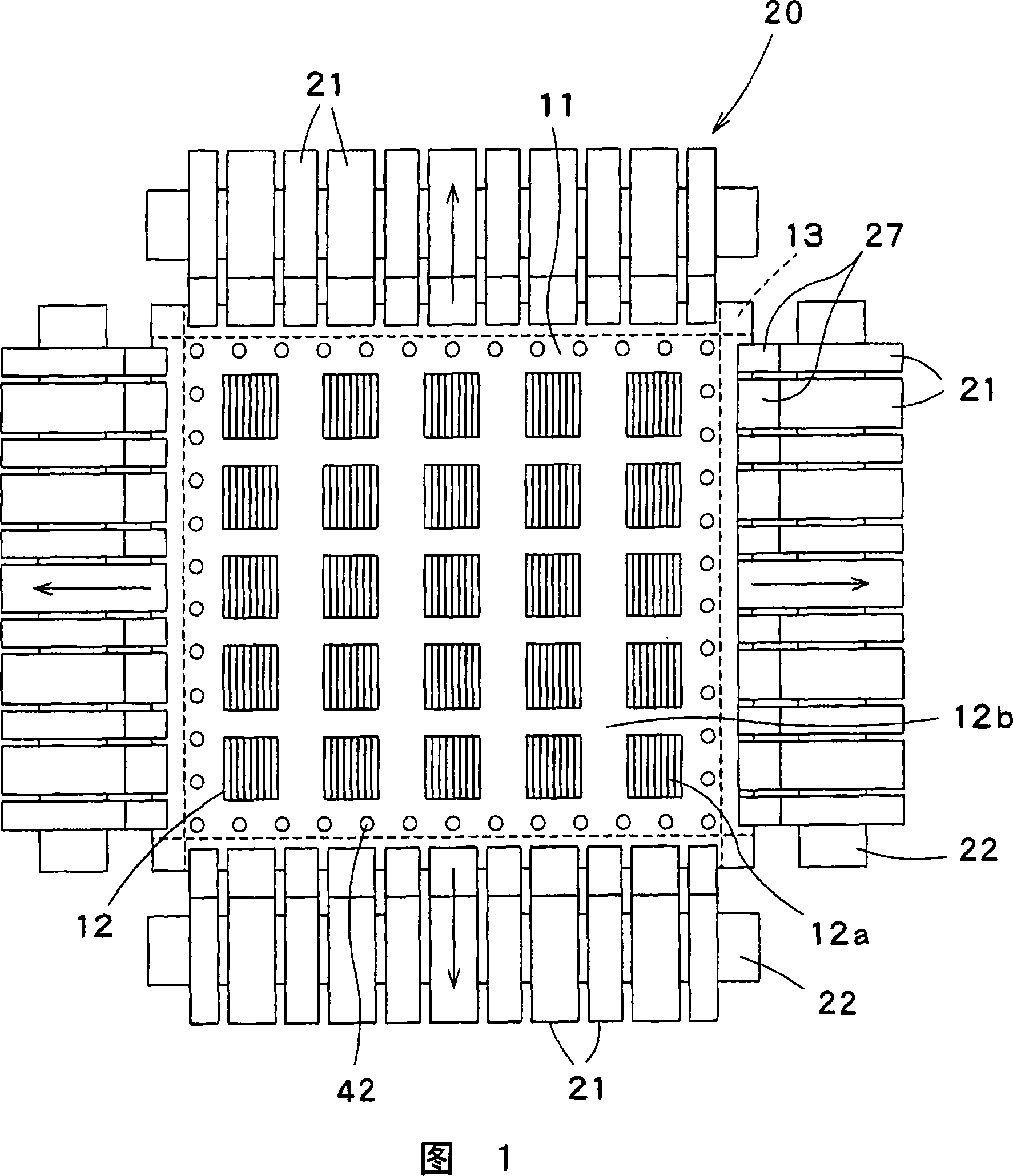

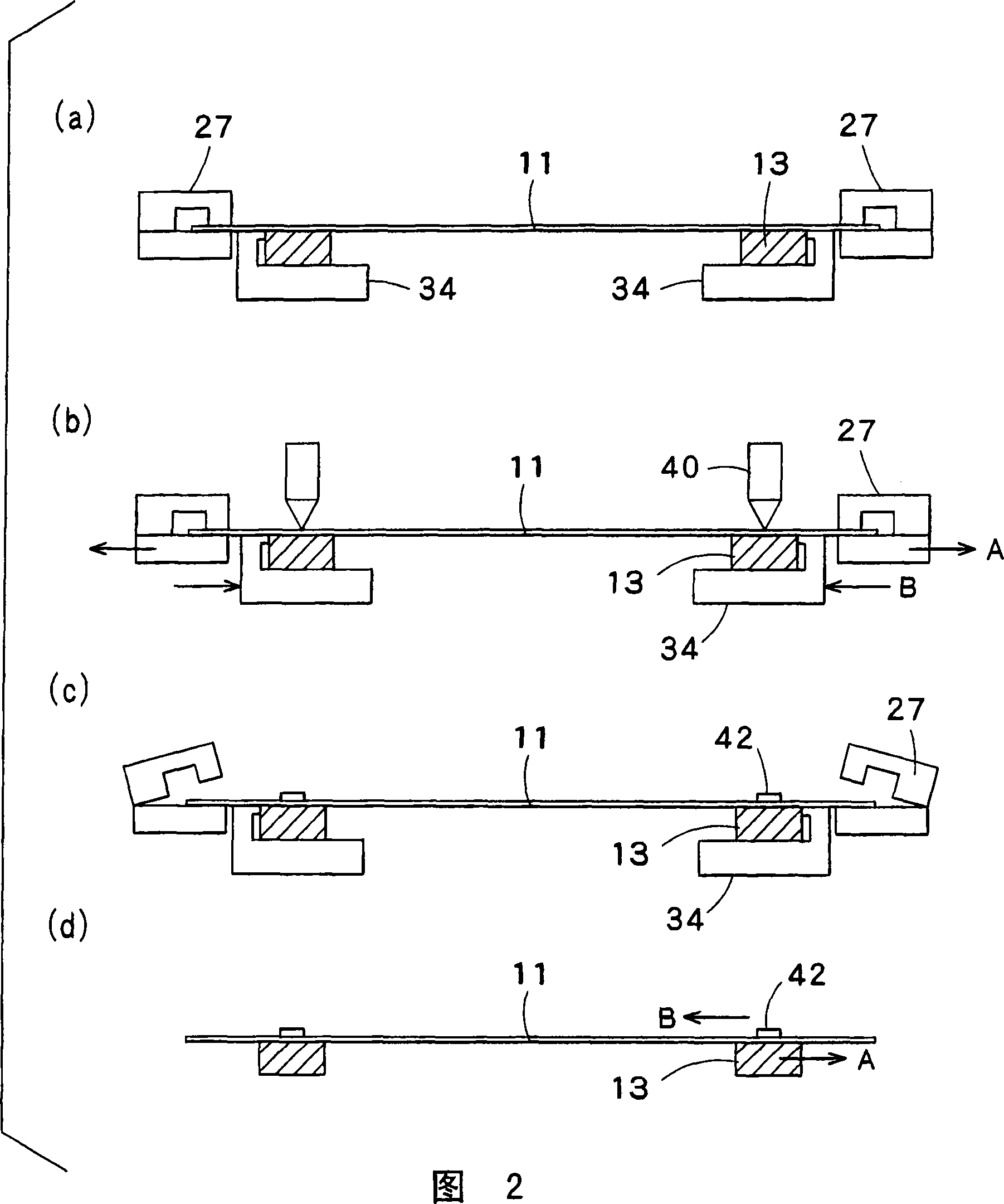

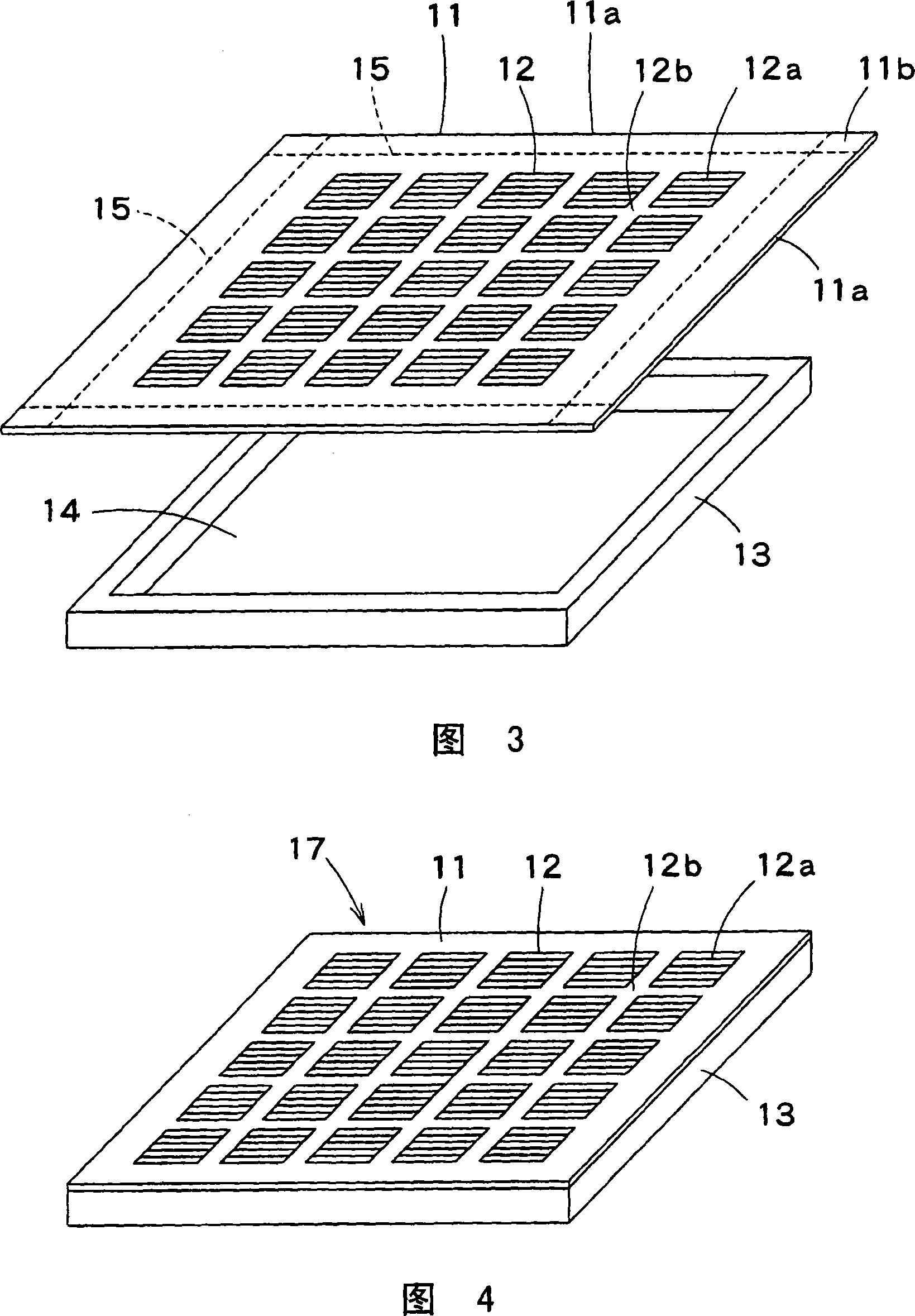

[0065] Fig. 1 is a schematic plan view of a framing device for a thin metal plate according to an embodiment of the present invention, Fig. 2 is a schematic cross-sectional view showing the sequence of framing operations performed by the framing device, and Fig. 3 is a schematic sectional view showing the metal sheet processed by the framing device. A schematic perspective view of the thin plate and the frame, Fig. 4 is a schematic ...

no. 2 Embodiment approach

[0092] The present invention can be applied to the case where an arbitrary rectangular metal mask (also referred to as a metal sheet) that needs to be kept in a flat state without deformation and slack is mounted on a rectangular frame-shaped frame (also referred to as a frame), but is preferably applied as A metal mask used for vapor deposition multi-faceted masks for the manufacture of organic EL elements that require high precision. Hereinafter, preferred embodiments of the present invention will be described by taking, as an example, a metal mask used as a multi-faceted mask for vapor deposition in the production of an organic EL element.

[0093] FIG. 20 is a schematic perspective view showing a metal mask and a frame-shaped frame processed by a frame mounting device (also called a thin metal plate frame mounting device) according to an embodiment described later, and FIG. A schematic perspective view of the formed mask assembly.

[0094] In FIG. 20 , 101 is a rectangula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com