Polyamic acid solution, and polyimide film and applications thereof

A technology of polyimide film and polyamic acid, which is applied in the field of polyimide film and polyamic acid solution, can solve the mismatch of film heat resistance, dimensional stability and mechanical performance process requirements, polyamic acid slurry Solve problems such as high solid content of the material and cannot meet the requirements of panel coating, etc., to achieve the effects of improving molecular structure stability, improving process performance and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

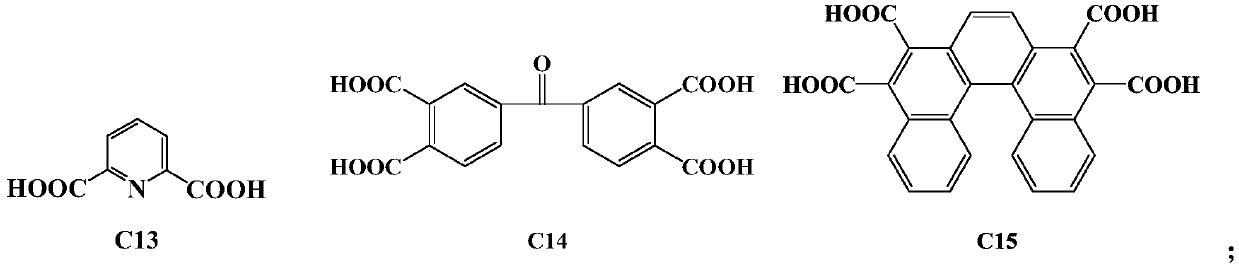

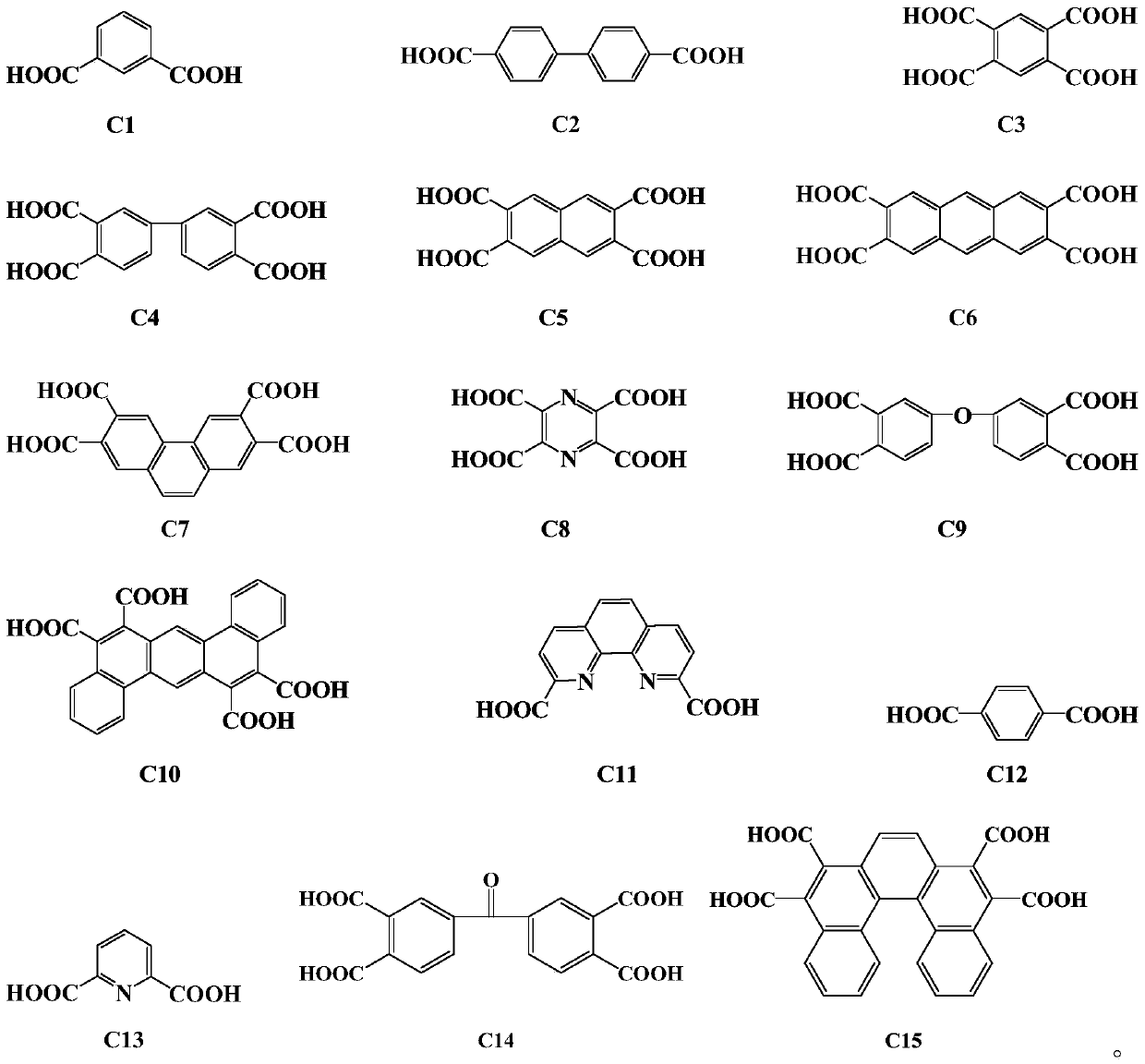

Method used

Image

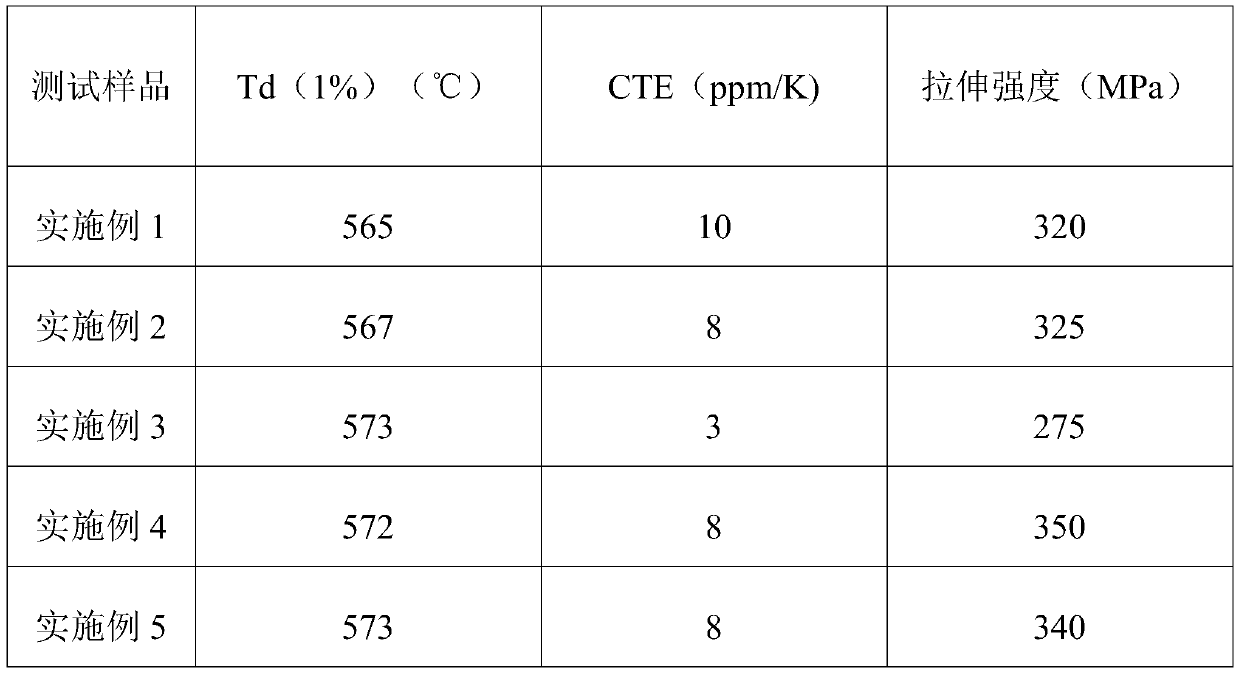

Examples

Embodiment 1

[0065] Add 5.67g of diamine compound B1 and 95g of N-methylpyrrolidone into the reaction flask respectively, start the mechanical stirring, replace the air in the flask with nitrogen, and place the system in an ice-water bath after the monomers are completely dissolved. Add 14.7g of A2 to the mixed solution in 4 times, and control the reaction temperature not to exceed 15°C. After the addition, the system naturally returns to room temperature and stirs for 6h, then adds 0.41g of compound C1, and continues stirring for 18h at room temperature to obtain a solid content of 18wt%. Polyamic acid solution (PAA1). The viscosity of the polyamic acid solution at 25° C. was tested to be 4800 cP.

Embodiment 2

[0067] Add 5.535g of diamine compound B1 and 94g of N-methylpyrrolidone into the reaction flask, turn on the mechanical stirring, replace the air in the flask with nitrogen, and add 1.0g of SiO 2 Inorganic nanoparticles (particle size: 20nm), after stirring for 30 minutes, place the system in an ice-water bath, add 14.7 g of A2 to the above mixed solution in 4 times, control the reaction temperature not to exceed 15°C, and the system will naturally return to room temperature after the addition Stir at low temperature for 6 h, then add 0.30 g of compound C, and continue stirring at room temperature for 18 h to obtain a polyamic acid solution (PAA2) with a solid content of 18 wt%. The viscosity of the polyamic acid solution at 25° C. was tested to be 7100 cP.

Embodiment 3

[0069] Add 3.89g of diamine compounds B1, 4.02g of B3 and 105g of N-methylpyrrolidone into the reaction flask respectively, start the mechanical stirring, replace the air in the flask with nitrogen, and add 1.1g of SiO 2 Inorganic nanoparticles (particle size: 20nm), after stirring for 30 minutes, put the system in an ice-water bath, add A13.27g and A2 10.29g to the above mixed solution in 4 times, control the reaction temperature not to exceed 15°C, after the addition, the system Naturally return to room temperature and stir for 6 hours, then add 0.38 g of compound C3, and continue stirring at room temperature for 18 hours to obtain a polyamic acid solution (PAA3) with a solid content of 18 wt%. The viscosity of the polyamic acid solution at 25° C. was tested to be 7800 cP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com