Patents

Literature

38results about How to "Solve the problem of solidification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

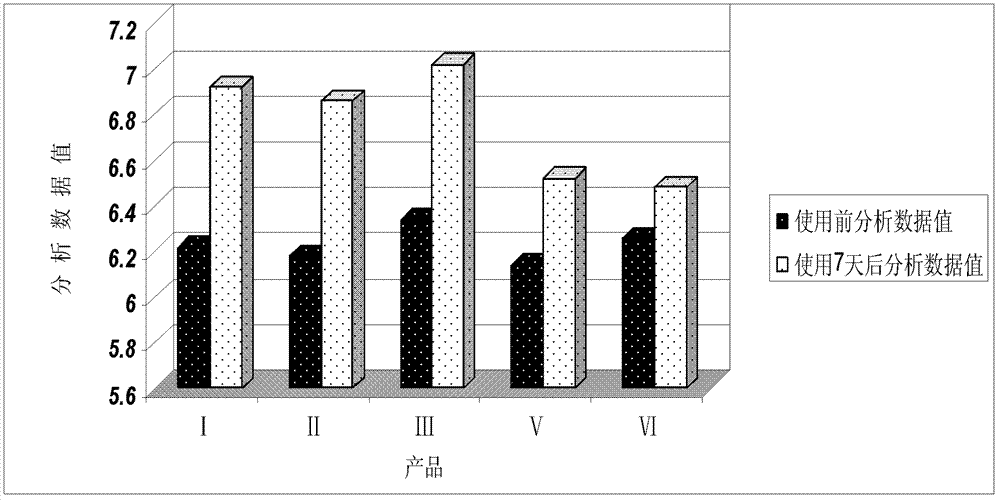

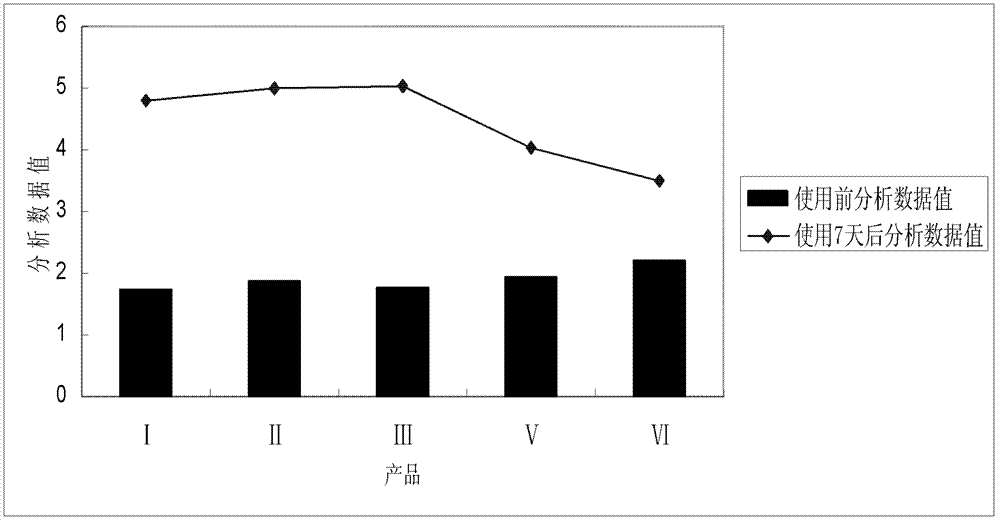

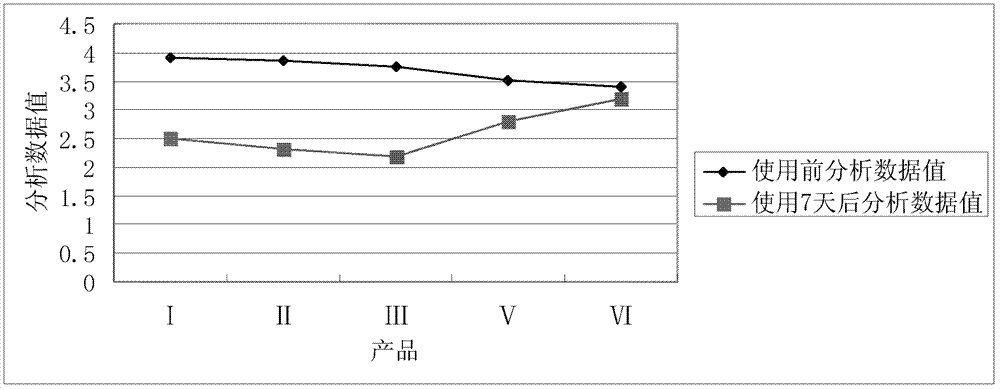

Essential oil added type skin care product

ActiveCN102600056APromote absorptionImprove absorption rateCosmetic preparationsToilet preparationsLiquid productIrritation

The invention provides an essential oil added type skin care product which is prepared from the following raw materials in percent by weight: 15-20 percent of lavender essential oil, 1-5 percent of sweet orange essential oil, 1-2 percent of rose flower essential oil, 2-4 percent of clary sage essential oil, 3-5 percent of rosemary essential oil, 2-4 percent of chamomile essential oil, 1-2 percentof arabian Jessamine essential oil, 10-15 percent of vitamin E and the balance of jojoba oil. According to the invention, the raw materials are mixed, and are subjected to ultrasonic oscillation to obtain a uniform liquid product with small oil drop diameter, so that the essential oil added type skin care product is obtained. The essential oil added type skin care product provided by the invention has the advantages of little irritation, good permeability and capability of remarkably improving the sub-health state of the skin within a short time to recover the skin health from inside to outside.

Owner:GUANGZHOU FRASLANE COSMETIC

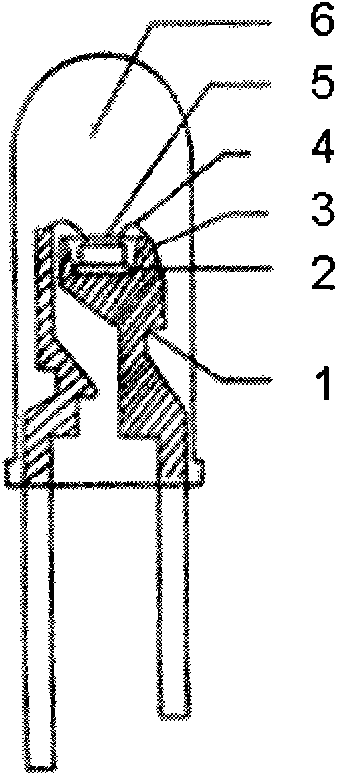

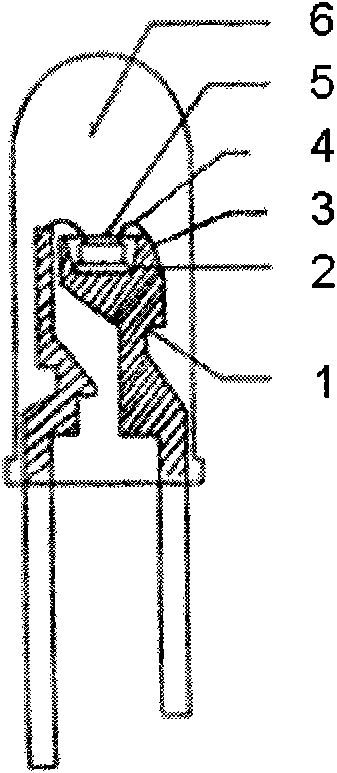

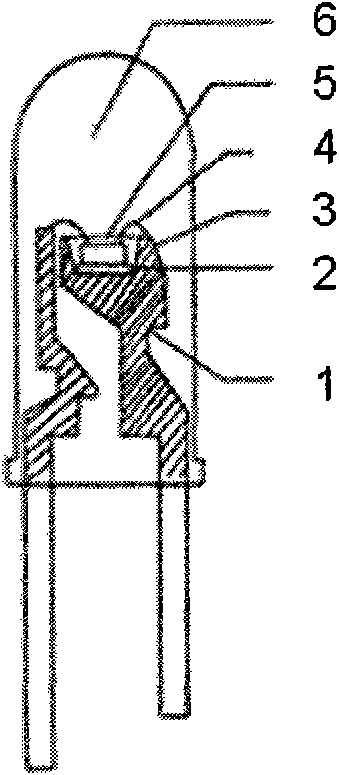

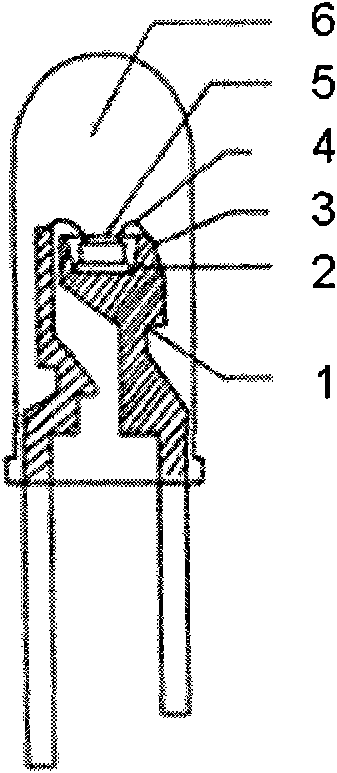

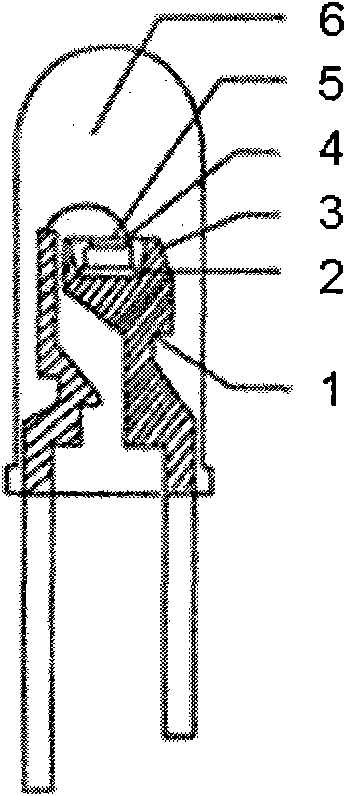

Light-emitting diode and preparation method thereof

The invention discloses a light-emitting diode (LED). The LED at least comprises a bracket, an LED chip and a light-emitting layer arranged on the LED chip and is characterized in that: the light-emitting layer is a mixed system of one or more kinds of fluorescent powder capable of sending out light with various colors and an adhesive requiring double curing; and the adhesive is an adhesive of a double curing system consisting of ultraviolet curing-thermocuring, ultraviolet curing-microwave curing, ultraviolet curing-anaerobic curing or ultraviolet curing-electron beam curing. The light-emitting layer solves the problems of colloid solidification and fluorescent powder sedimentation in the process of coating the fluorescent powder, so the LED has the advantages of improving the uniformity of the fluorescent powder on the chip, enhancing the adhesive property between the light-emitting layer and the chip and shortening the curing time of the light-emitting layer.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

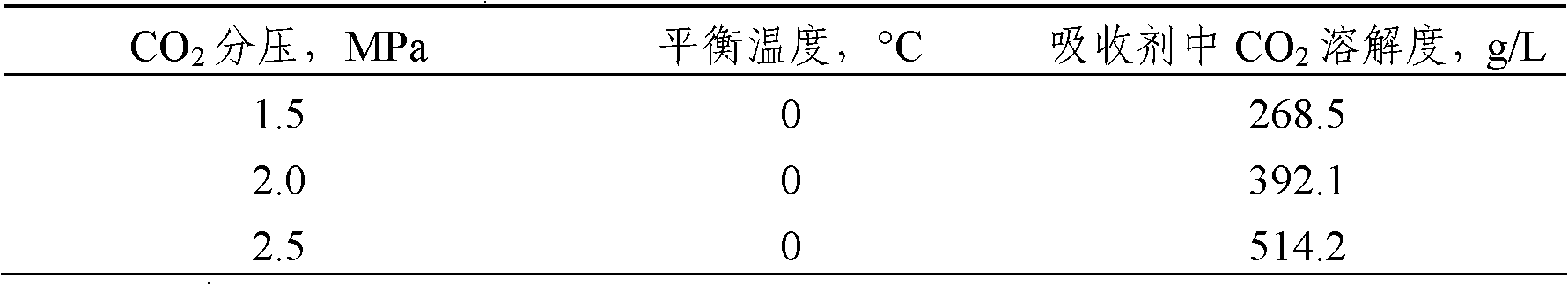

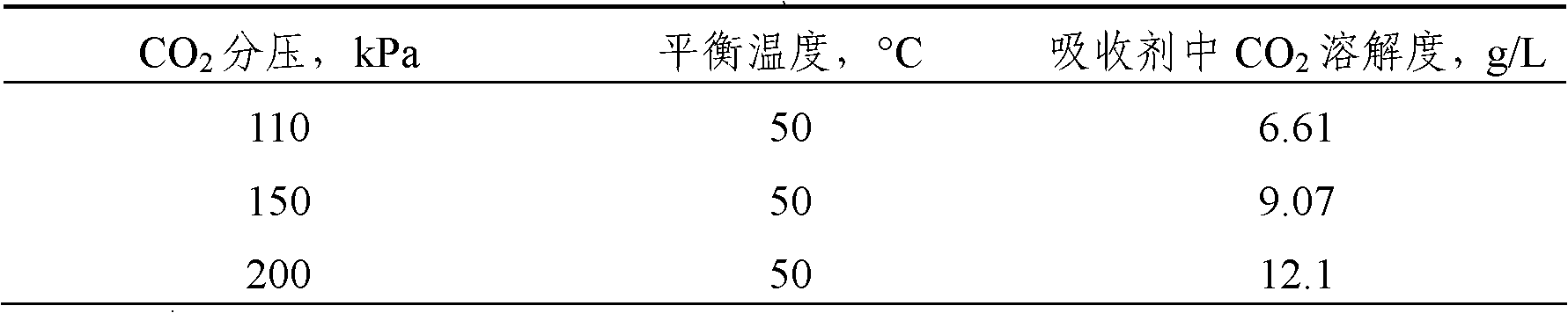

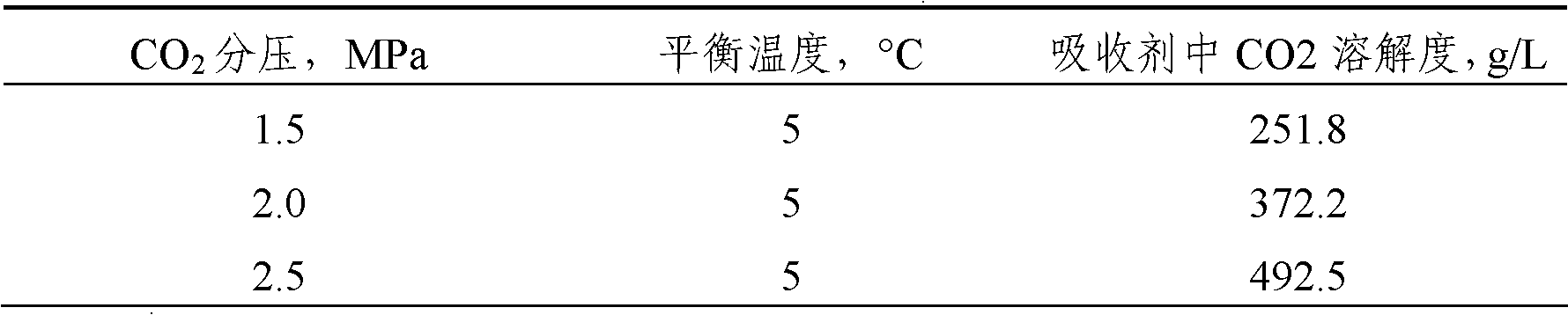

Absorbent for collecting and separating CO2 and use thereof

InactiveCN102151458ASolve viscositySolve the problem of solidificationProductsCarbon compoundsOrganic solventCo2 absorption

The invention provides an absorbent for collecting and separating CO2, which contains 5 to 95 weight percent of dimethyl carbonate and 95 to 5 weight percent of organic solvent, wherein the organic solvent is one or more of hydrocarbon, ether or ester solvents. The invention has the advantages that: the absorbent is prepared by mixing the dimethyl carbonate and the organic solvent, so the freezing point of the dimethyl carbonate can be lowered, the CO2 absorption effect of the dimethyl carbonate is not changed, but even is increased; the problem that sharp viscosity increase or freezing during the use of the dimethyl carbonate at a lower temperature influence the use effect of the dimethyl carbonate is solved; and thus, the process is simplified effectively and cost is reduced.

Owner:TSINGHUA UNIV

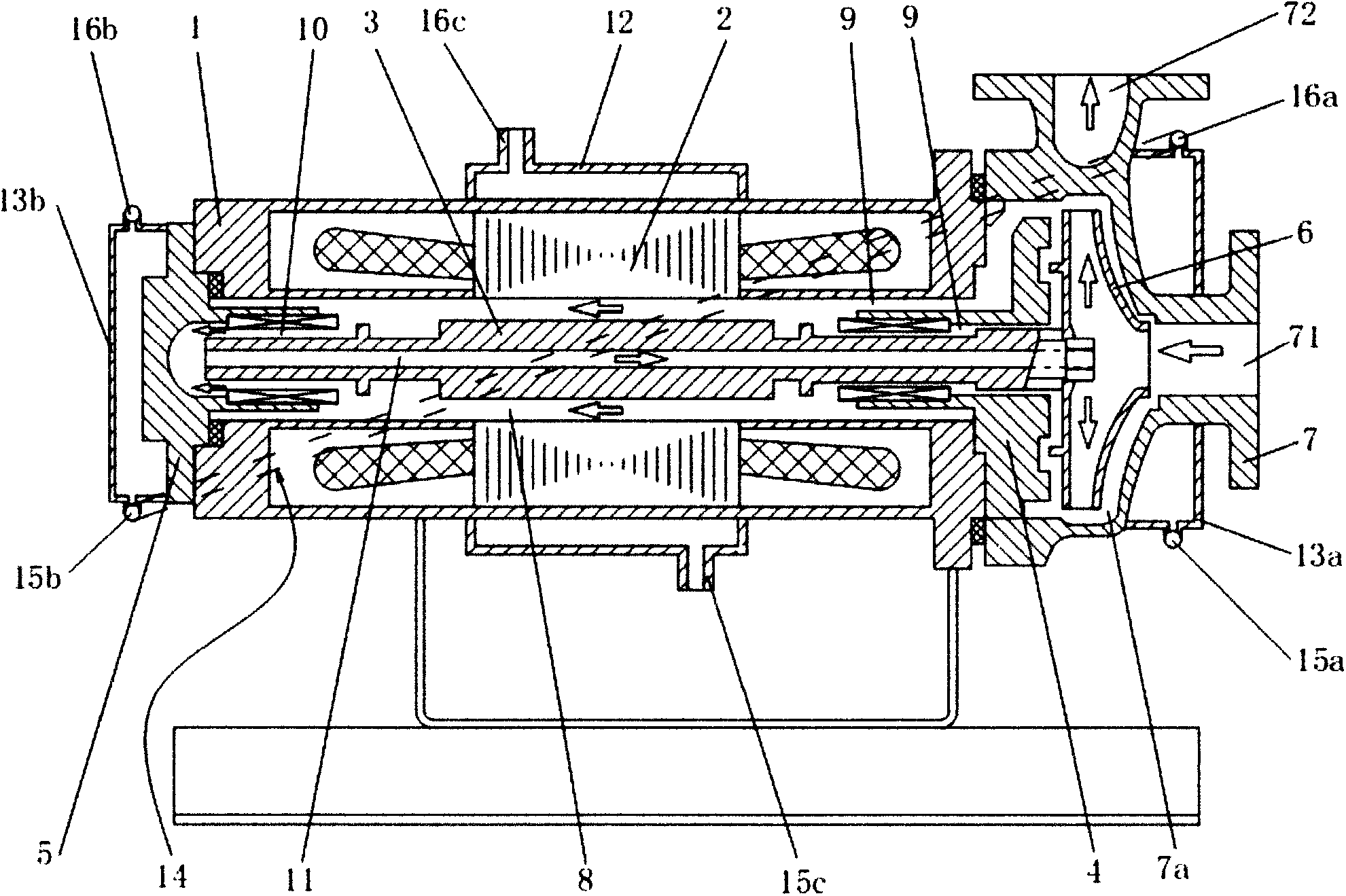

Shield electric pump for conveying media easy to solidify and crystallize

InactiveCN103912524ASolve the problem of solidificationIncrease temperatureSpecific fluid pumpsPump componentsImpellerWater jacket

The invention relates to a shield electric pump for conveying media easy to solidify and crystallize. The shield electric pump comprises a machine case, a stator and a rotor. The rotor is installed through a front bearing pedestal and a rear bearing pedestal which are arranged at the two ends of the machine case respectively. The stator is coaxially arranged in the machine case in a sleeved mode. The rotor protrudes and extends out of the front bearing pedestal and is fixedly connected with an impeller. The impeller is covered with a pump body, and the pump body and the machine case are fixed in a sealed mode. The side end of the pump body is provided with a feed port communicated with a pump cavity of the pump body. The upper end of the pump body is provided with a discharge port communicated with the pump cavity. An air gap passage is formed between the stator and the rotor. The position, corresponding to the stator, of the outer wall of the machine case is fixedly sleeved with a water jacket. Two steam jackets are fixedly arranged on the outer side of the pump body and the outer side of the rear bearing pedestal respectively in an attached mode. Through the arrangement of the steam jackets on the two sides and the water jacket, when solidified or crystallized media remain in the shield electric pump, the temperature of the shield electric pump can be raised by connecting steam to the shield electric pump so that the solidified or crystallized media can be molten; consequently, the problem that the media are solidified or crystallized is effectively and timely solved, and damage caused by blockage is avoided.

Owner:无锡市安化屏蔽电泵厂

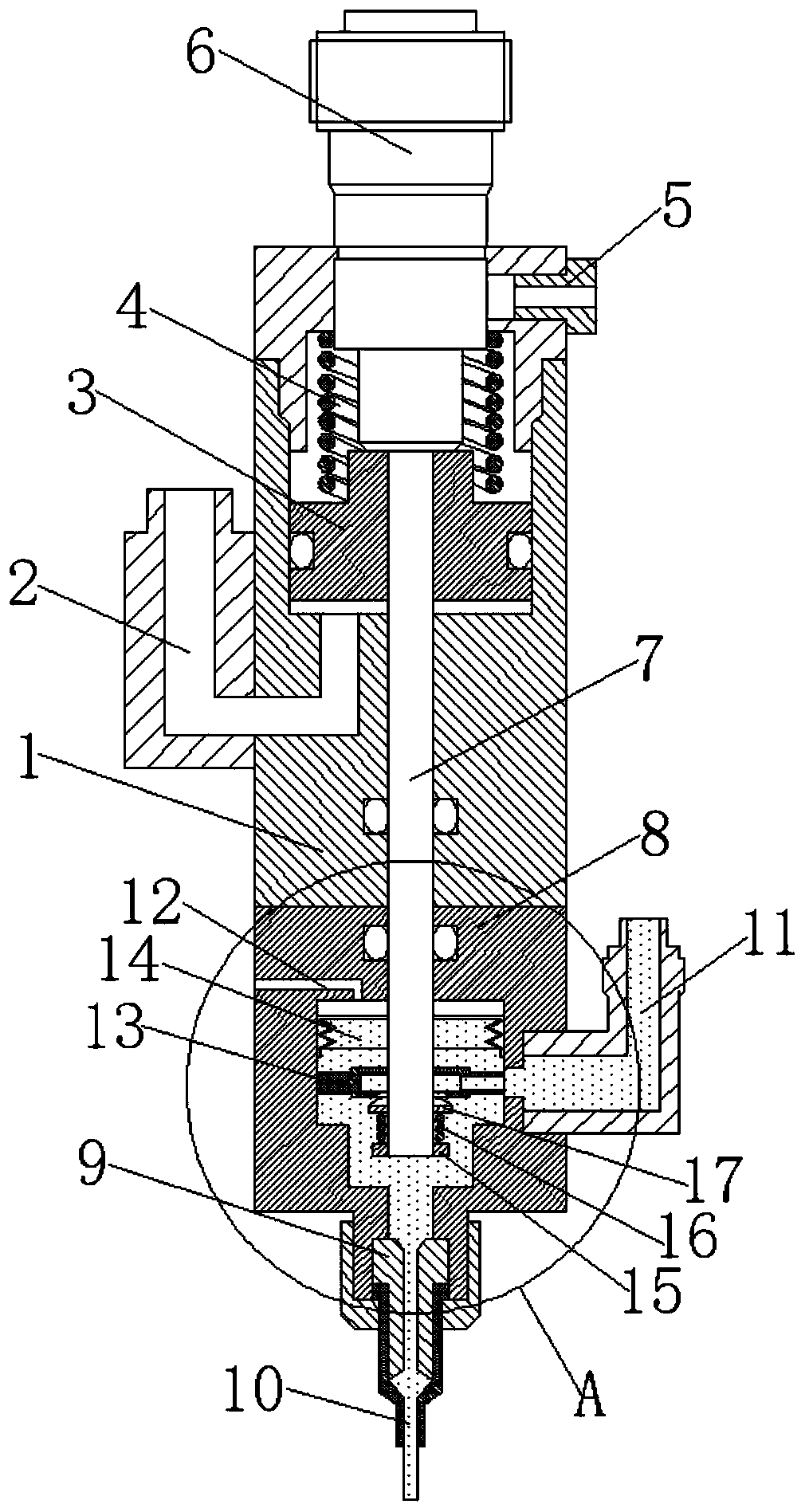

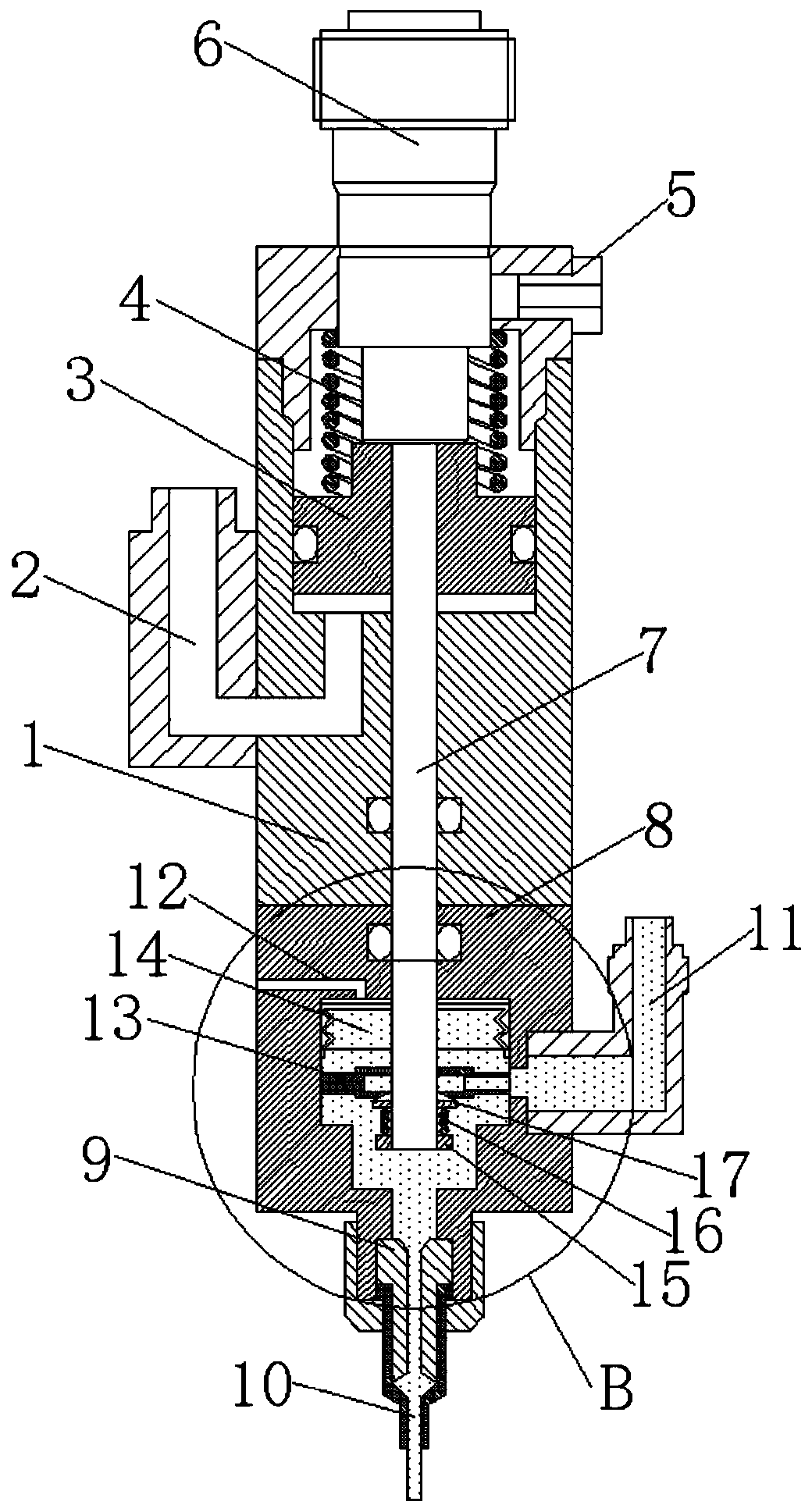

LED dispensing equipment for light emitting diode manufacturing

InactiveCN110976209AAvoid breakingSolve the problem of insufficient negative pressureLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to the technical field of dispensing equipment, and discloses LED dispensing equipment for light emitting diode manufacturing. The LED dispensing equipment comprises an upper valve body, one side of the upper valve body is fixedly connected with an air inlet, a piston is movably sleeved with the upper valve body, the upper part of the piston is fixedly connected with a largespring, and the upper part of the large spring is fixedly connected with a fine adjustment button, the upper portion of the other side of the upper valve body is fixedly connected with an air outlet,and a valve needle is fixedly connected to the bottom of the piston. The bottom of a capsule is fixedly and hermetically connected with a lower valve body, as the capsule is an elastic corrugated pipefitting, so that the valve needle drives the capsule to stretch in the process that the piston rapidly lifts to drive the valve needle to ascend, although the ascending displacement of the valve needle is small, stretching of the capsule can provide enough negative pressure to timely suck back a glue solution, the problem that negative pressure generated by ascending of the valve needle is insufficient is solved, timely back suction is guaranteed, and the situations of glue dripping and glue leakage are avoided.

Owner:江苏合泓通讯技术有限公司

Process technique for furol waste liquid

InactiveCN101201168ASolve pollutionSolve the problem of solidificationIncinerator apparatusLiquid wasteSlag

The invention discloses a treatment technics for waste furfural liquid. The treatment technics fully mixes furfural mud and light components in a weight proportion of 1 to 1.5 to 2.4 and then the mixed furfural mud and light components burn completely. The technics completely solves the problems of the furfural slag solidification and the boiler coking after burning. Massive heat is generated through the burning of materials. Each kilogram of materials after can generate heat of 2400 kj after burning, thus saving partial fuel.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

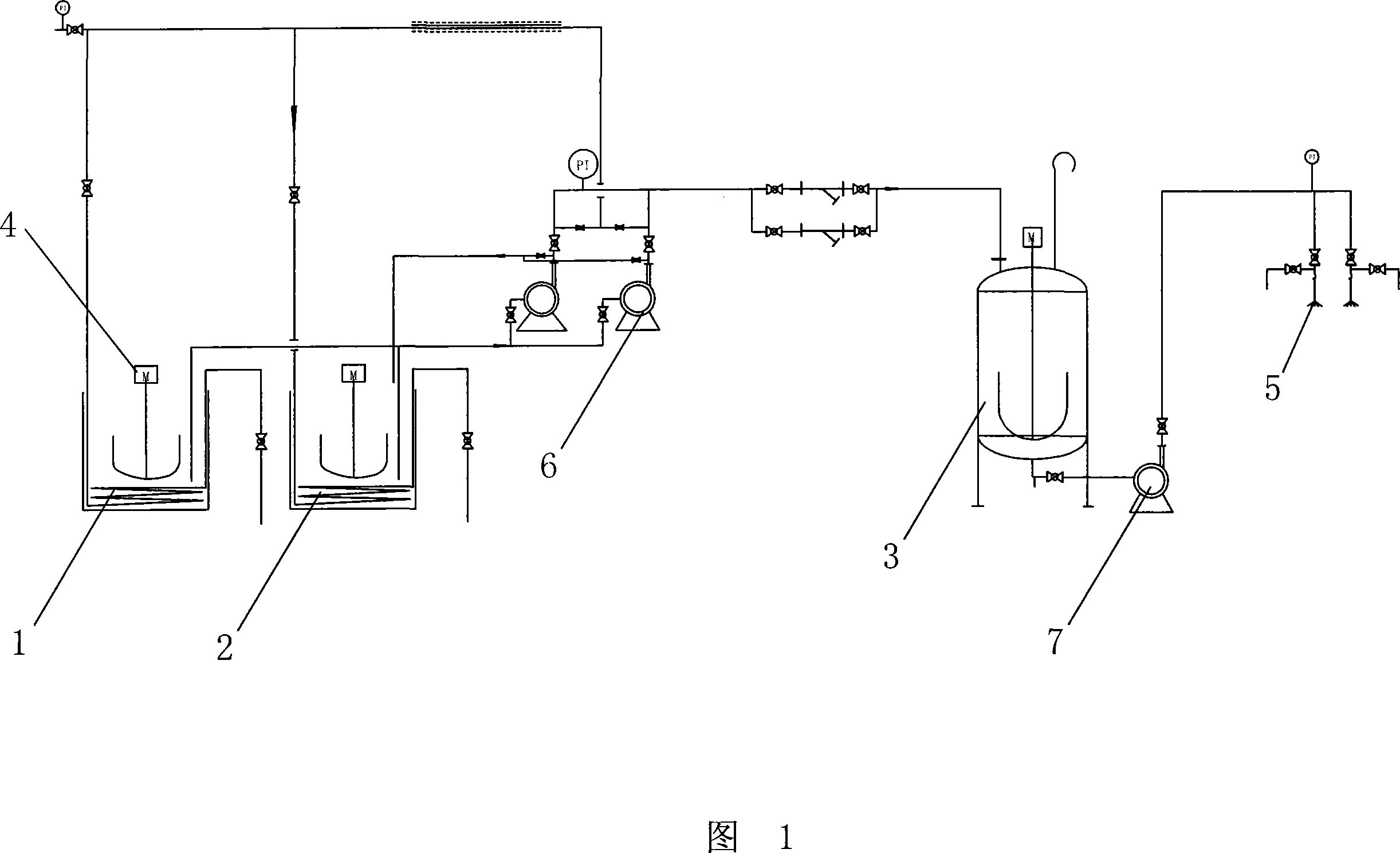

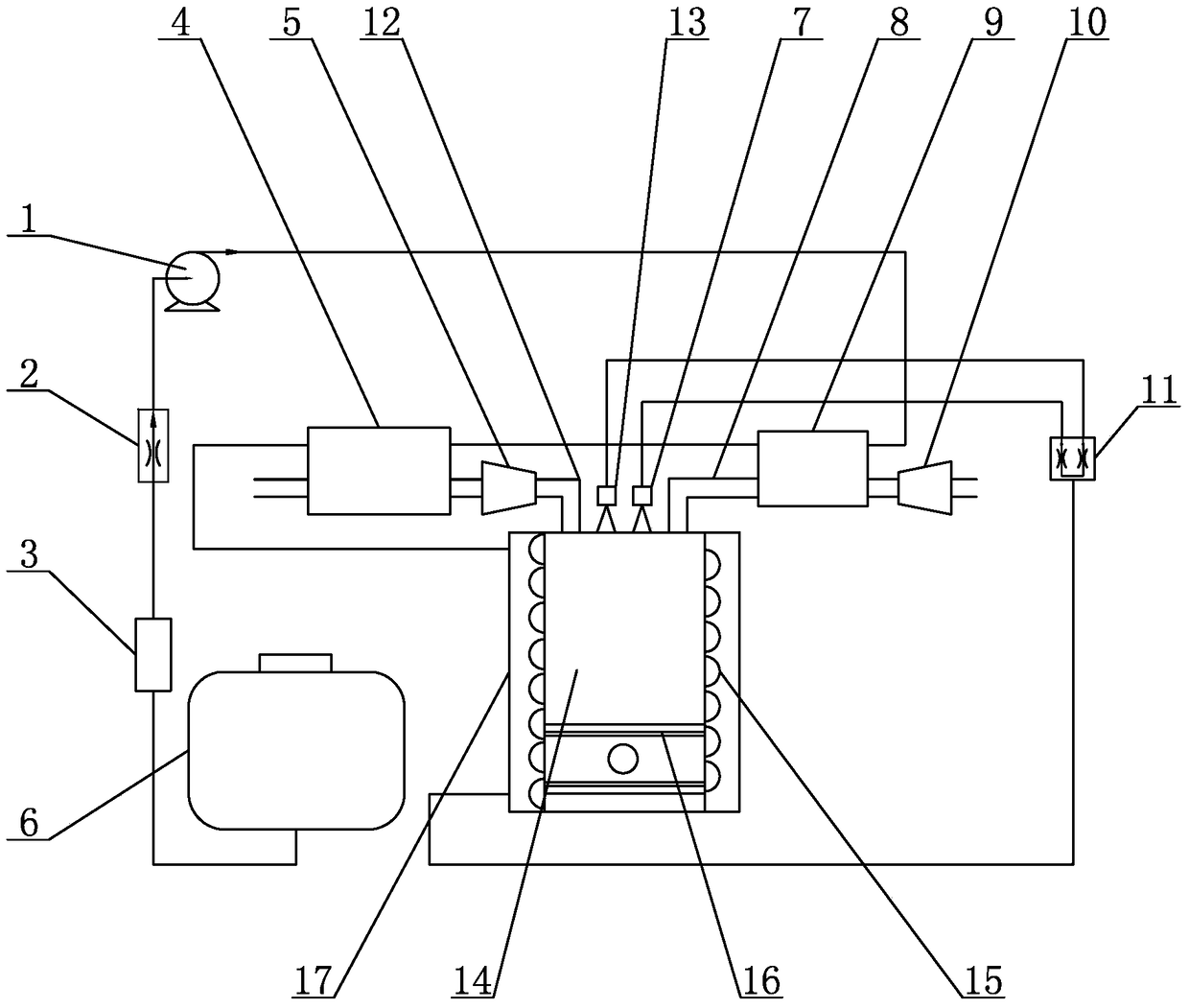

Chemical heat regeneration type diesel engine

InactiveCN105626254AImprove efficiencyImprove combustion efficiencyInternal combustion piston enginesThermal treatment of fuelHeat regenerationGas turbines

The invention discloses a chemical heat regeneration type diesel engine, belongs to the field of internal combustion engines, and solves the problems of lower efficiency and higher oil consumption in a traditional diesel engine. The chemical heat regeneration type diesel engine imitates working principles of a chemical heat regeneration type aloof ramjet and a chemical heat regeneration circulating gas turbine; and diesel is sprayed into a cylinder for burning after finishing the chemical heat regeneration process. When the engine is operated, the diesel flows out from an oil tank to supercharge to form high-pressure diesel after filtration and flow adjustment; the high-pressure diesel flows into a spiral cooling channel to absorb heat generated by burning of a fuel in the cylinder and dispersed to the wall surface of the cylinder; the chemical cracking is generated when protecting the wall surface to generate one part of gaseous micromolecule products; a switching valve is switched to a thermal fuel oil way; high-temperature cracking gas and non-cracked diesel steam enter a gaseous fuel nozzle by the switching valve, and then are sprayed into the cylinder for burning; when the engine is started, as a temperature field is not built, the diesel is still in a liquid state before entering the cylinder; the switching valve is switched to a cold fuel oil way; and the diesel is sprayed into the cylinder after being atomized by a liquid fuel nozzle.

Owner:HARBIN INST OF TECH

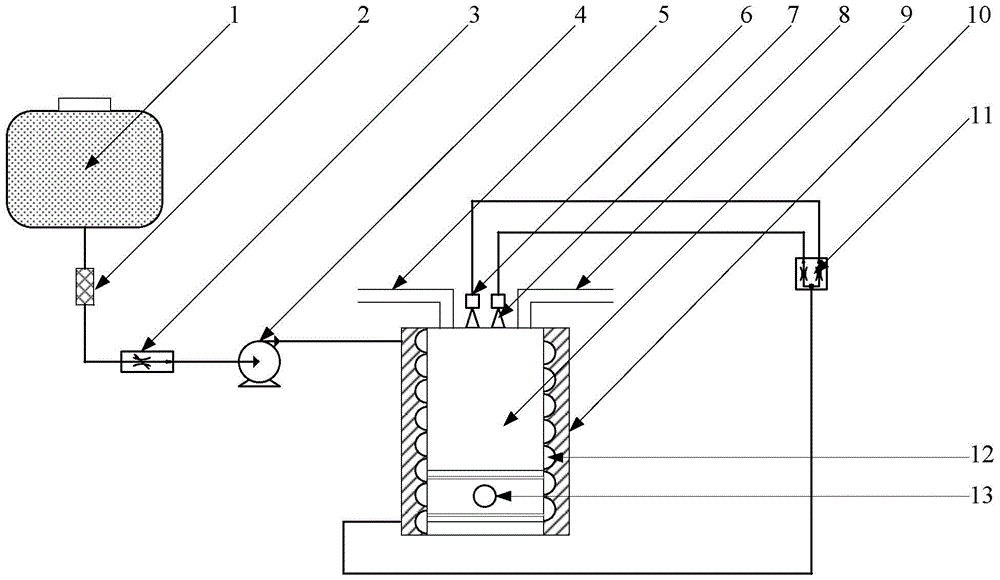

Preheating-type chemical regenerative diesel engine

ActiveCN105604694AReduce heat dissipationImprove efficiencyInternal combustion piston enginesThermal treatment of fuelIntercoolerGas turbines

The invention discloses a preheating-type chemical regenerative diesel engine, and relates to a diesel engine, and in particular to the preheating-type chemical regenerative diesel engine. By using the preheating-type chemical regenerative diesel engine, the problems that an existing diesel engine is lower in efficiency and higher in oil consumption are solved. An oil outlet of an oil tank of the preheating-type chemical regenerative diesel engine is connected with a supercharge pump through a flow regulating valve; the supercharge pump is connected with an inter cooler; the inter cooler is connected with an air cylinder through an air inlet pipe; a piston is arranged in the air cylinder; a cooling passage is arranged on the outer side wall of the air cylinder; a ceramic thermal insulating layer is mounted on the cooling passage in a sleeving manner; the inter cooler is connected with a diesel oil-tail gas heat exchanger; the air cylinder is connected with an exhaust-driven gas turbine through an exhaust pipe; the exhaust-driven gas turbine is connected with the diesel oil-tail gas heat exchanger; the air cylinder is connected with a switching valve; the switching valve is connected with the air cylinder through a gaseous fuel nozzle and a liquid fuel nozzle; the supercharge pump is connected with the inter cooler. The preheating-type chemical regenerative diesel engine belongs to the field of internal combustion engines.

Owner:HARBIN INST OF TECH

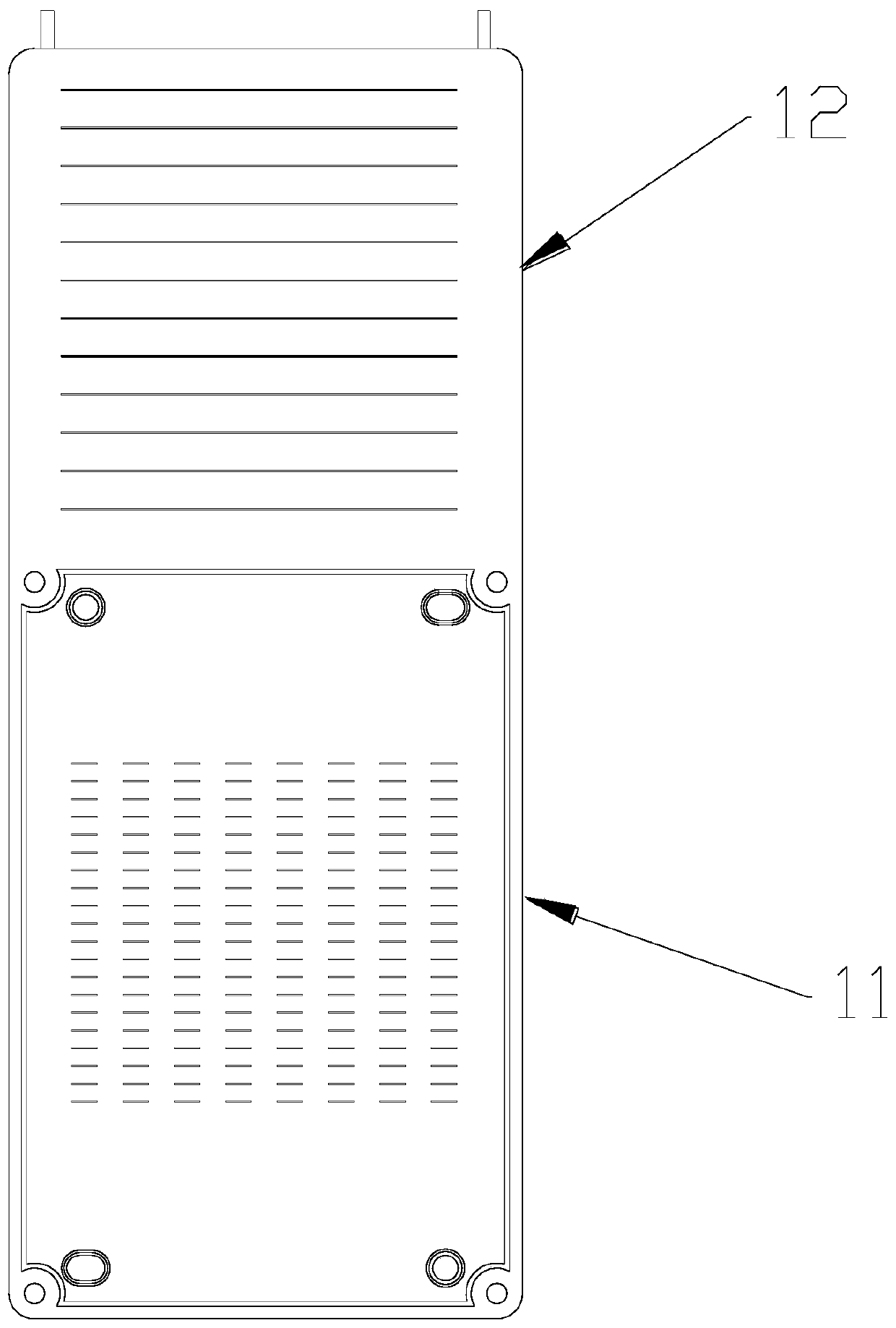

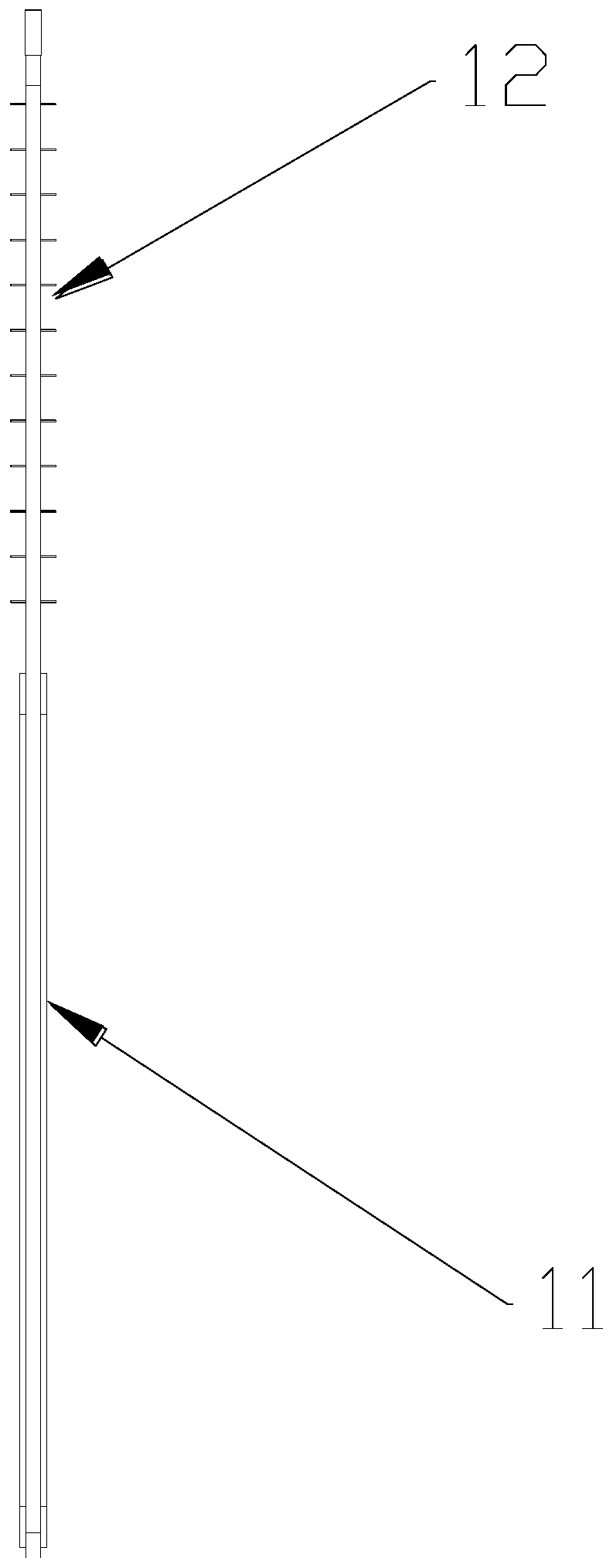

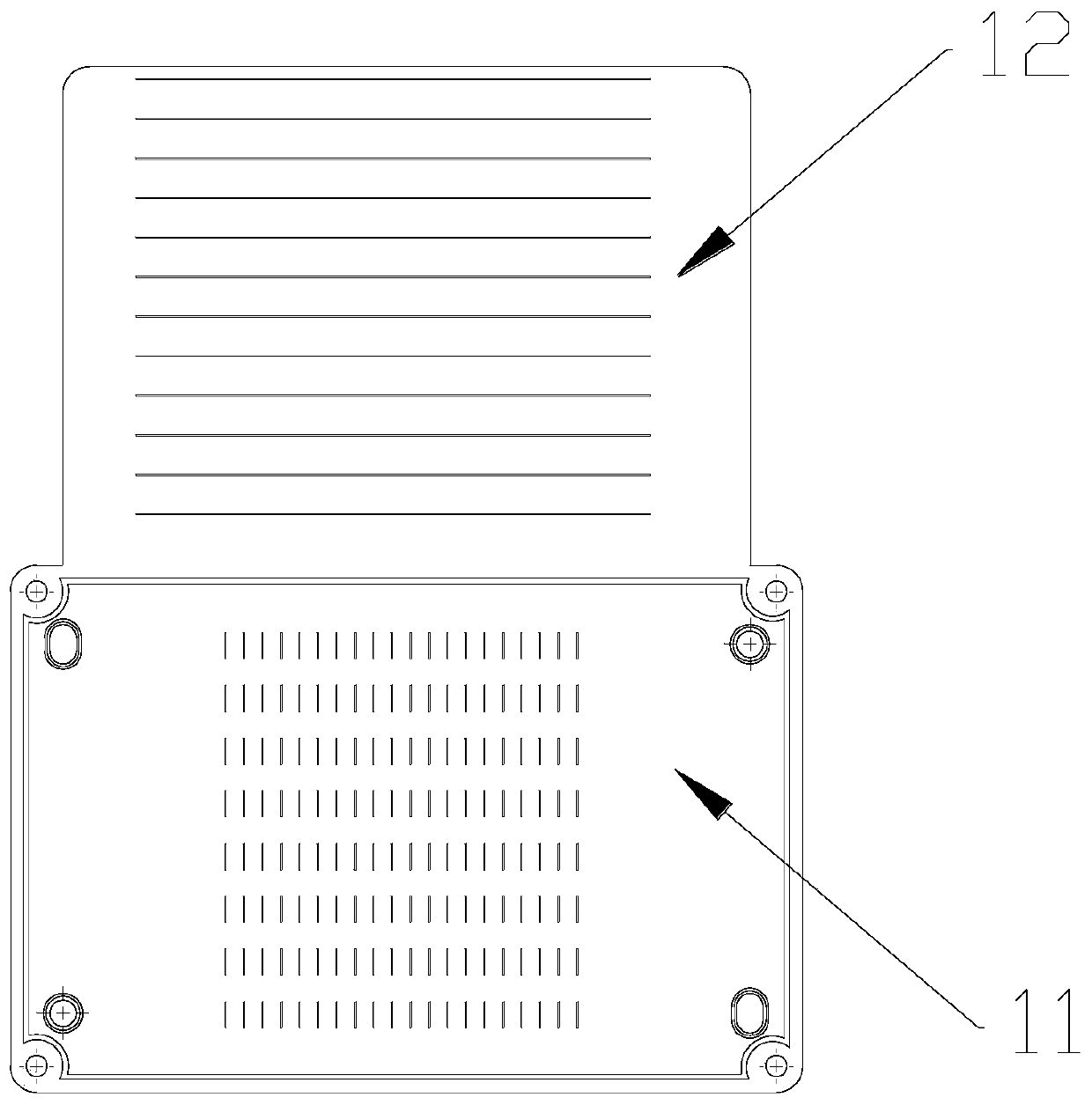

Heat pipe metal bipolar plate air-cooled (single) battery stack, vehicle and electronic device

PendingCN110416568AIncrease volumetric power densitySolve the problem of solidificationFuel cell heat exchangeMotive system fuel cellsThermal energyFuel cells

The invention discloses a heat pipe metal bipolar plate air-cooled (single) battery stack, a vehicle and an electronic device. The heat pipe metal bipolar plate comprises a power generation zone and aheat dissipation zone. Communicated sealed spaces are in the power generation zone and the heat dissipation zone and used for phase change heat transfer of a heat transfer medium. The selection of the heat transfer medium can be correspondingly selected according to different application environments. A heat pipe bipolar plate is stored in a sealed space inside the power generation zone in the form of a liquid or solid medium when the heat pipe bipolar plate does not work. A fuel cell works and generates heat energy. A liquid or solid heat transfer medium absorbs heat, is gasified and comes into the sealed space inside the heat dissipation zone. After low temperature air is encountered in the heat dissipation zone, the gaseous heat transfer medium gives out heat and flows back to the sealed space inside the power generation zone to continue to absorb heat, thereby transmitting heat to the power generation zone. A fuel cell stack composed of the heat pipe bipolar plate and a membrane electrode can directly solve the problem of heat dissipation through air cooling. The water cooling system of a fuel cell system is simplified.

Owner:苏州久安通氢能源科技有限公司

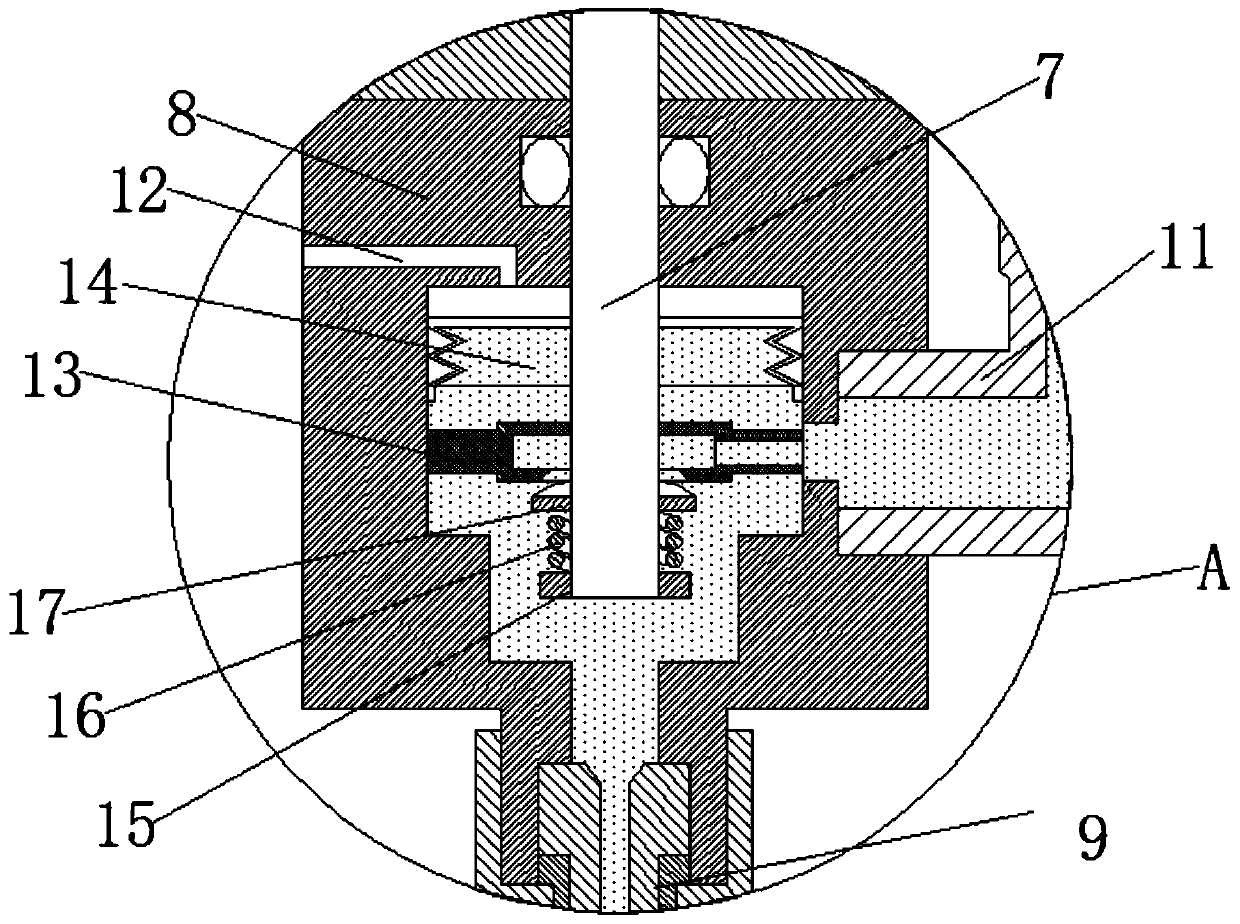

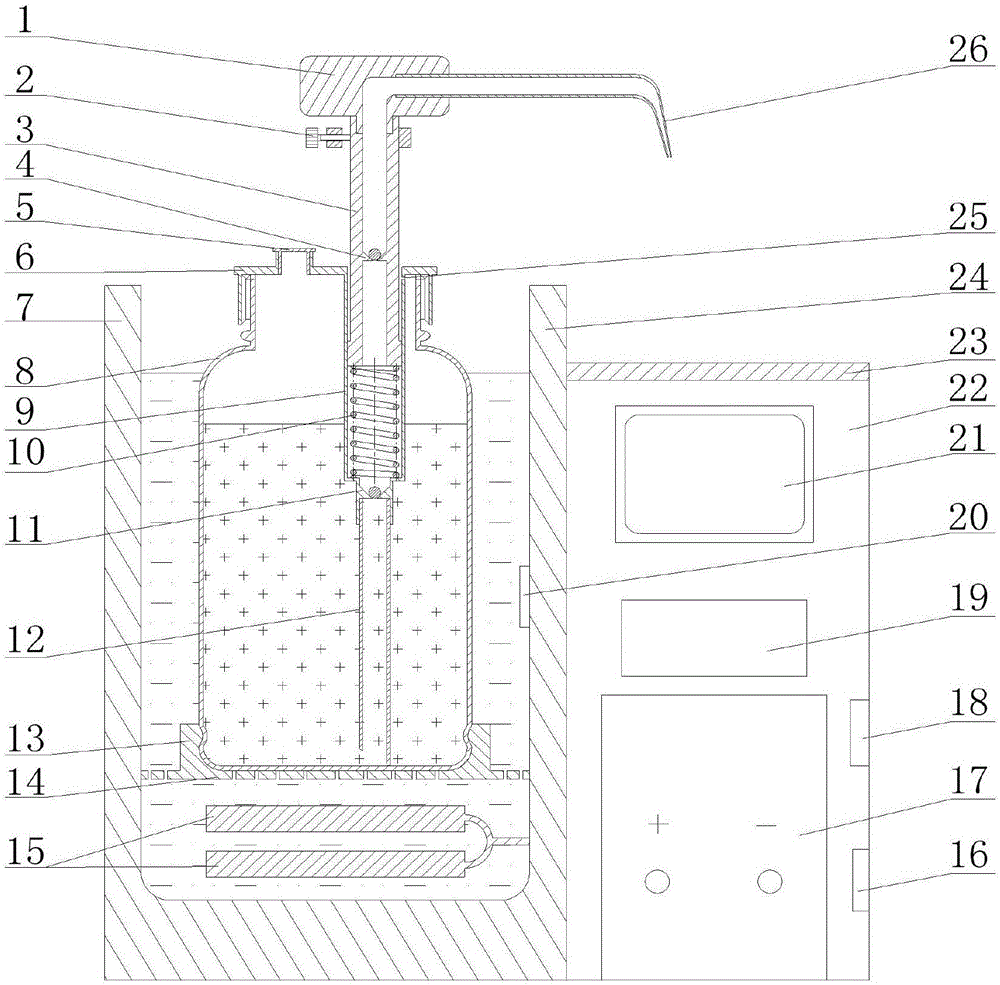

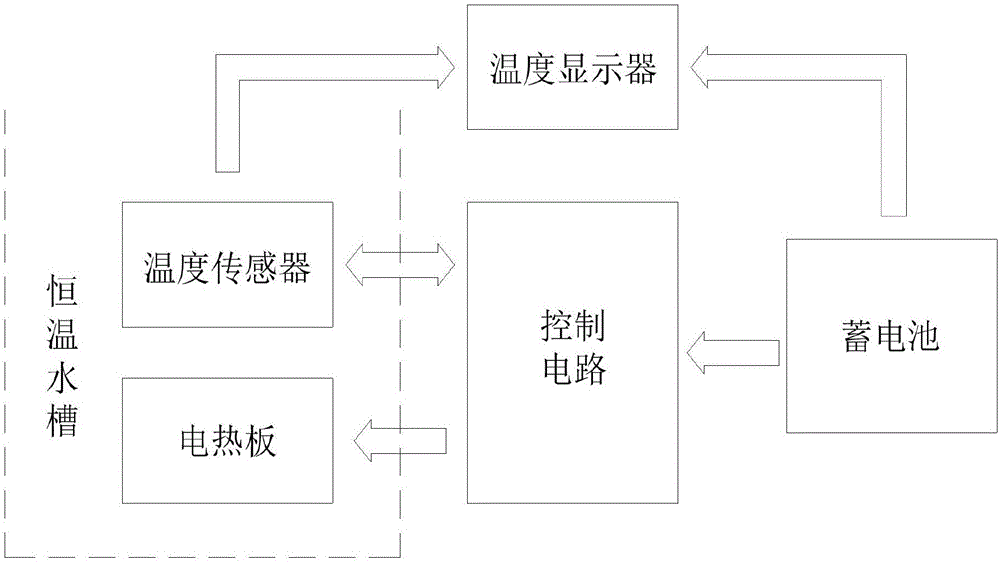

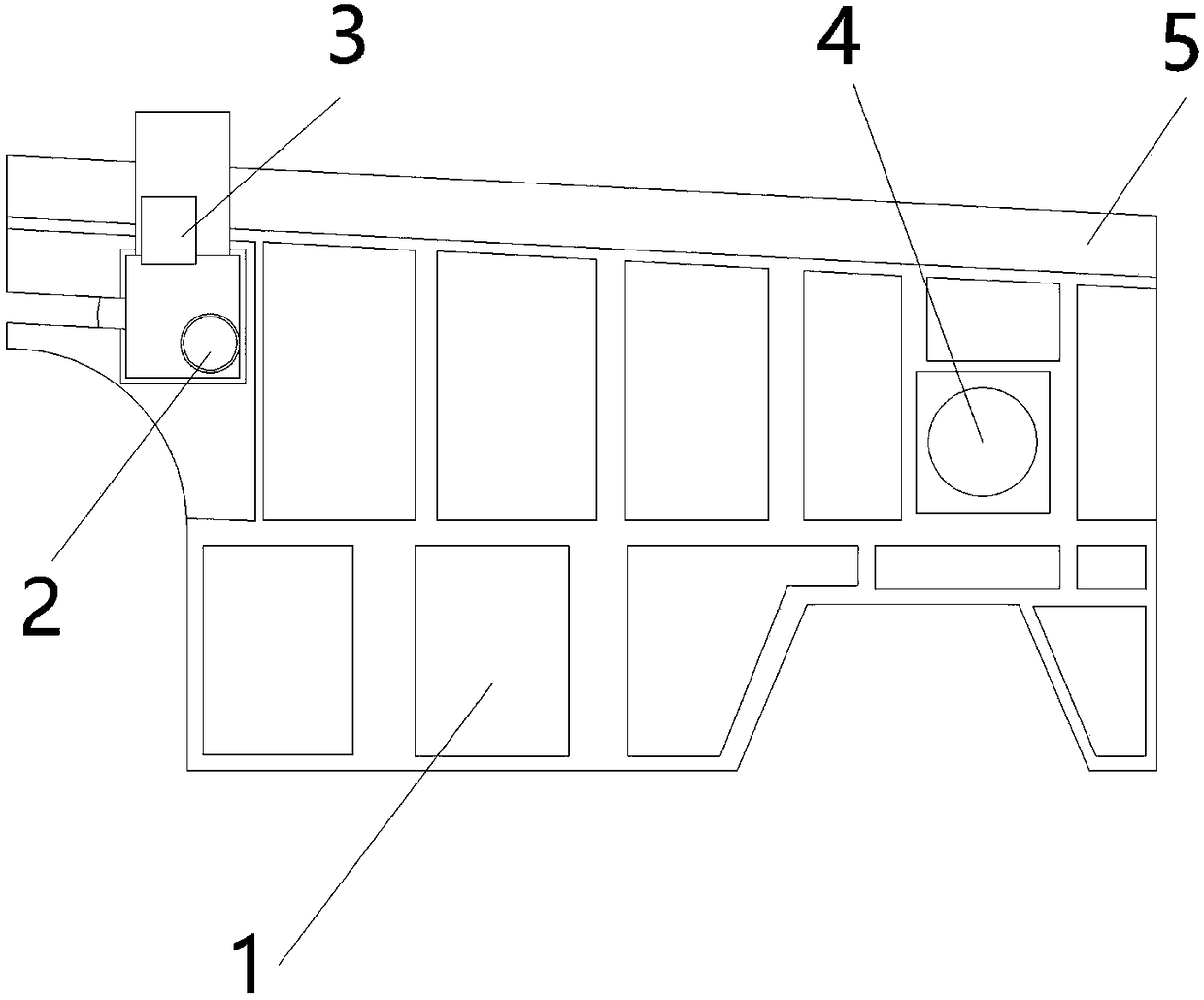

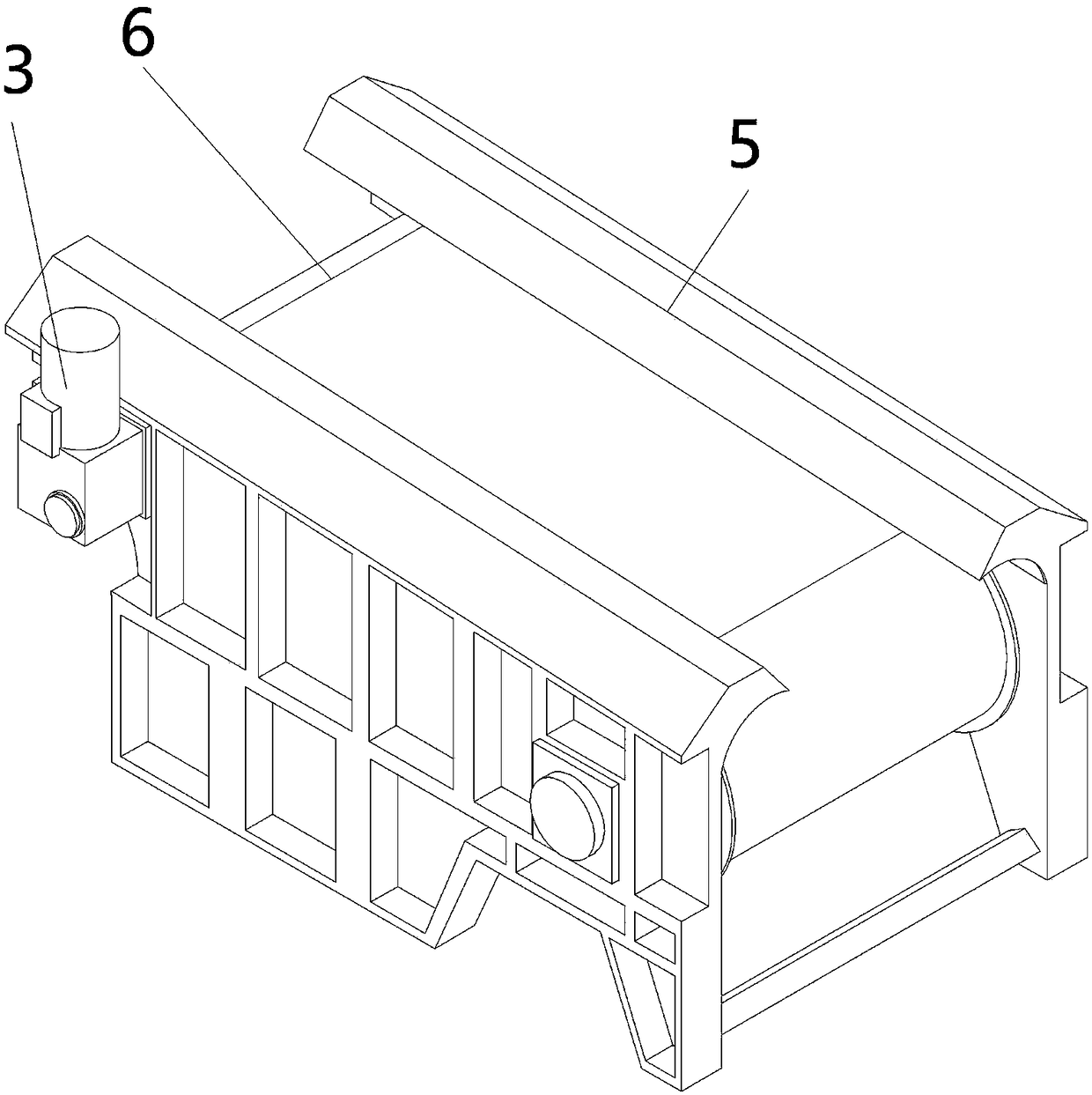

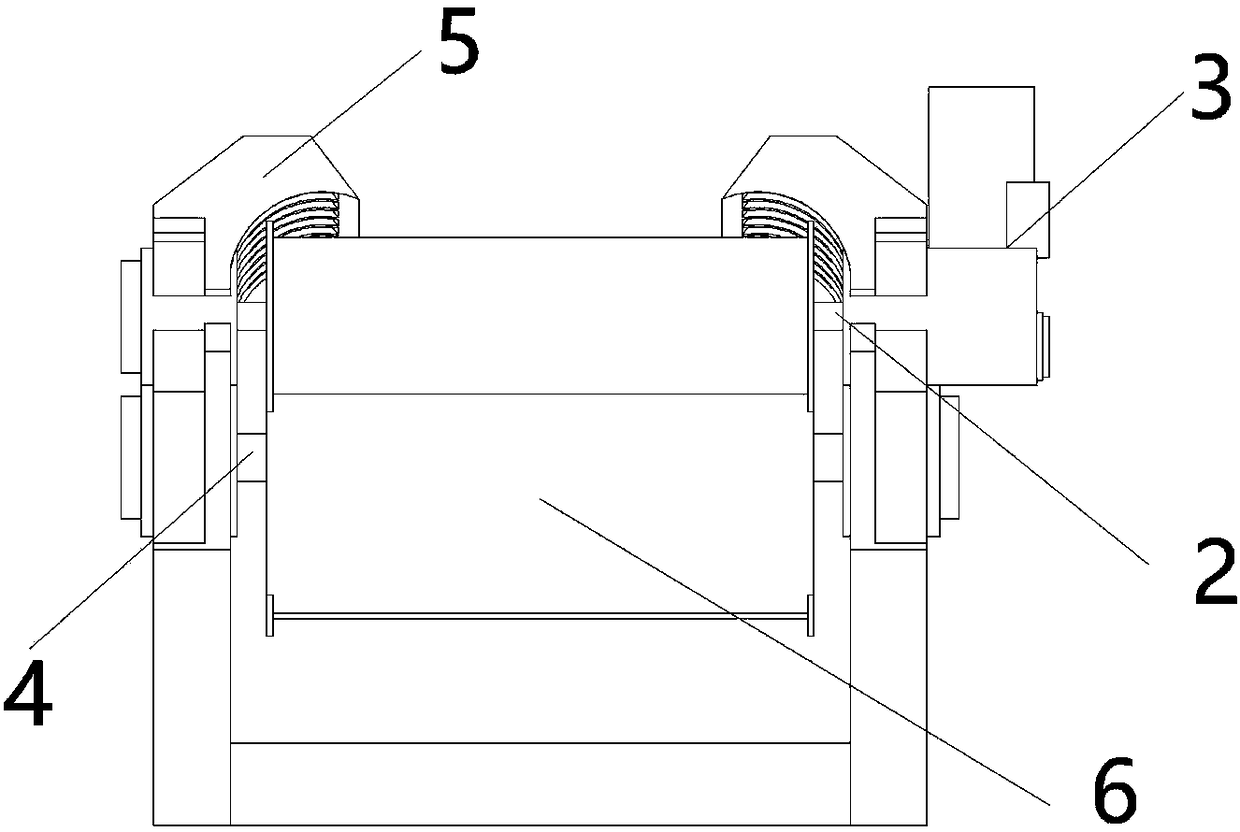

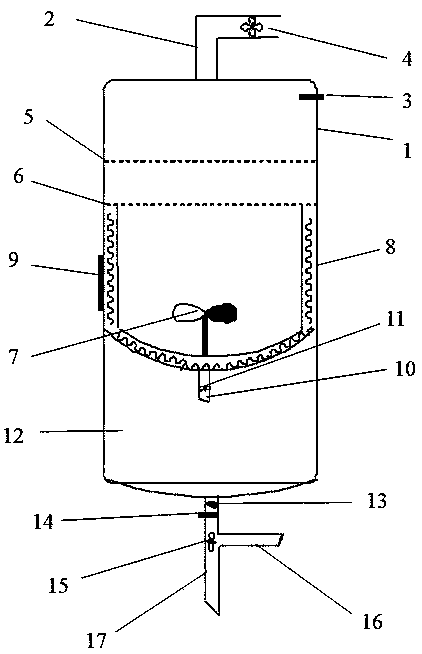

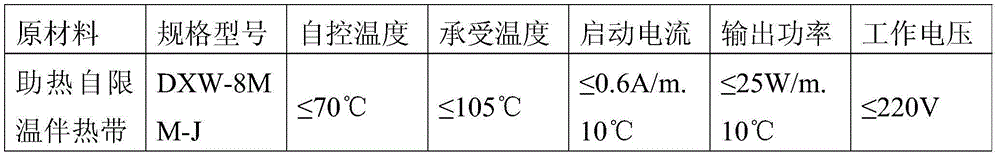

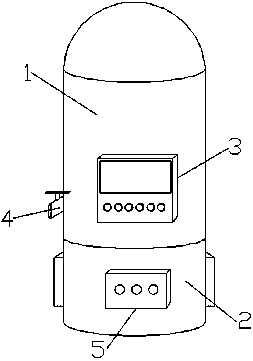

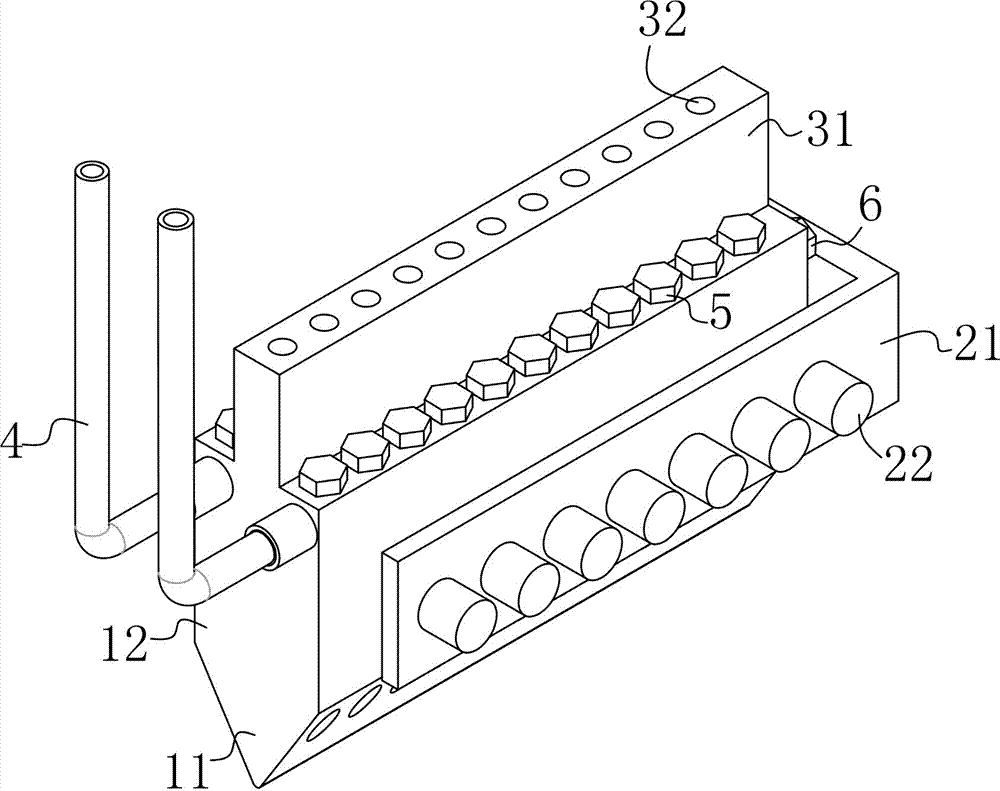

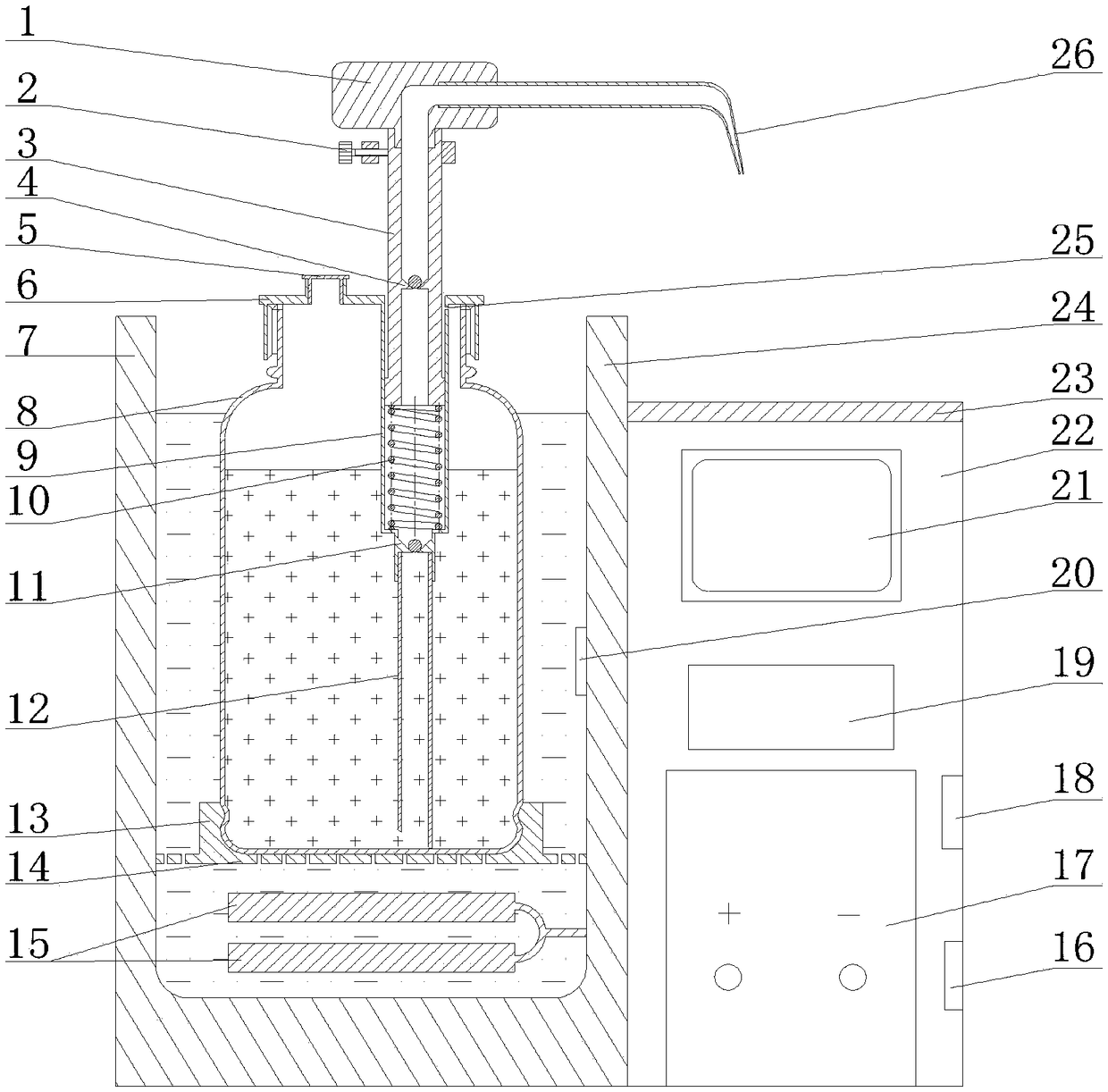

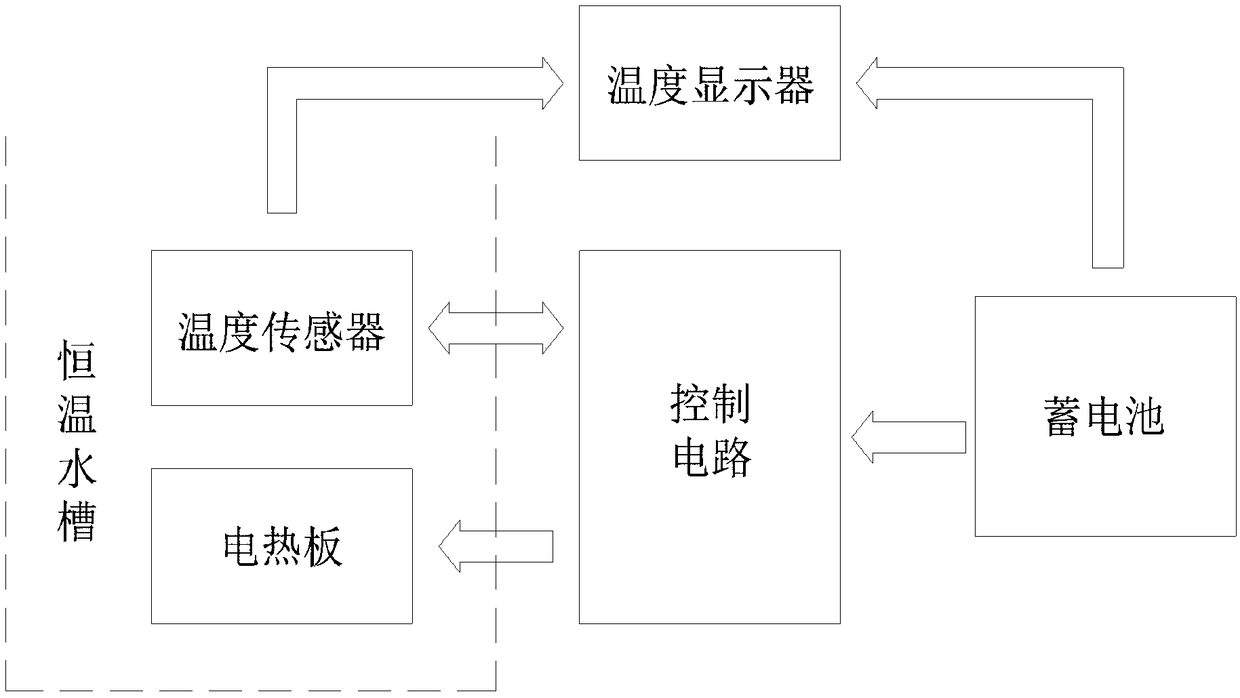

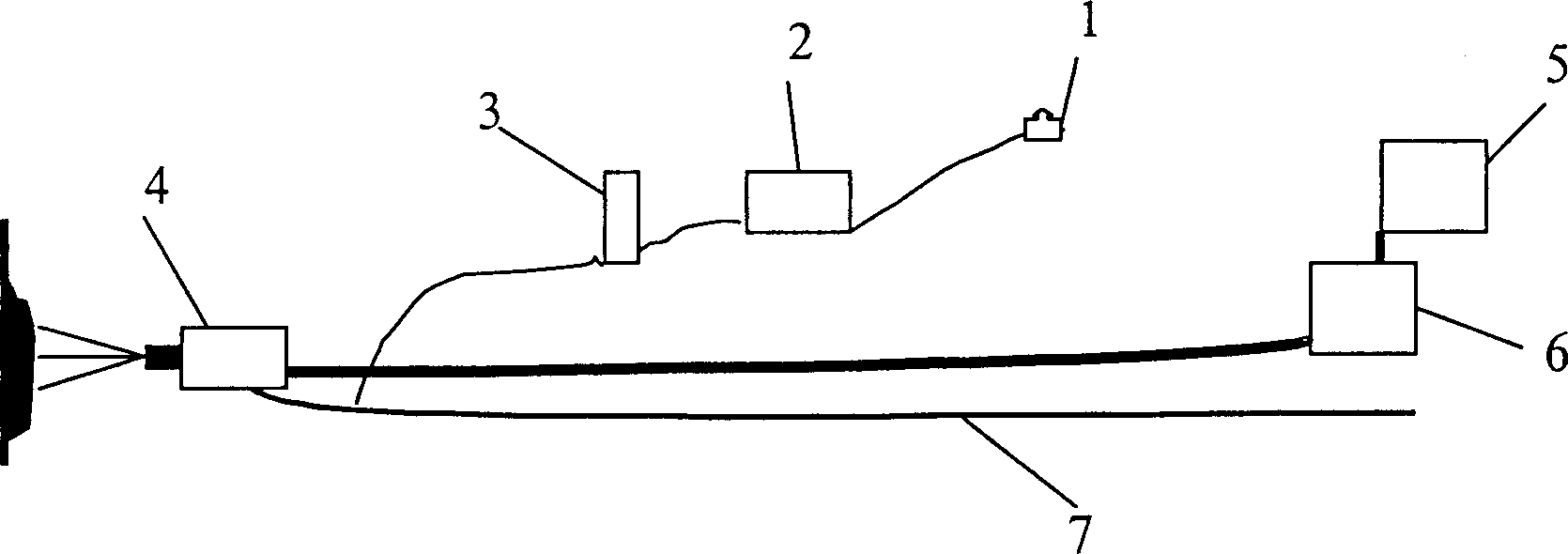

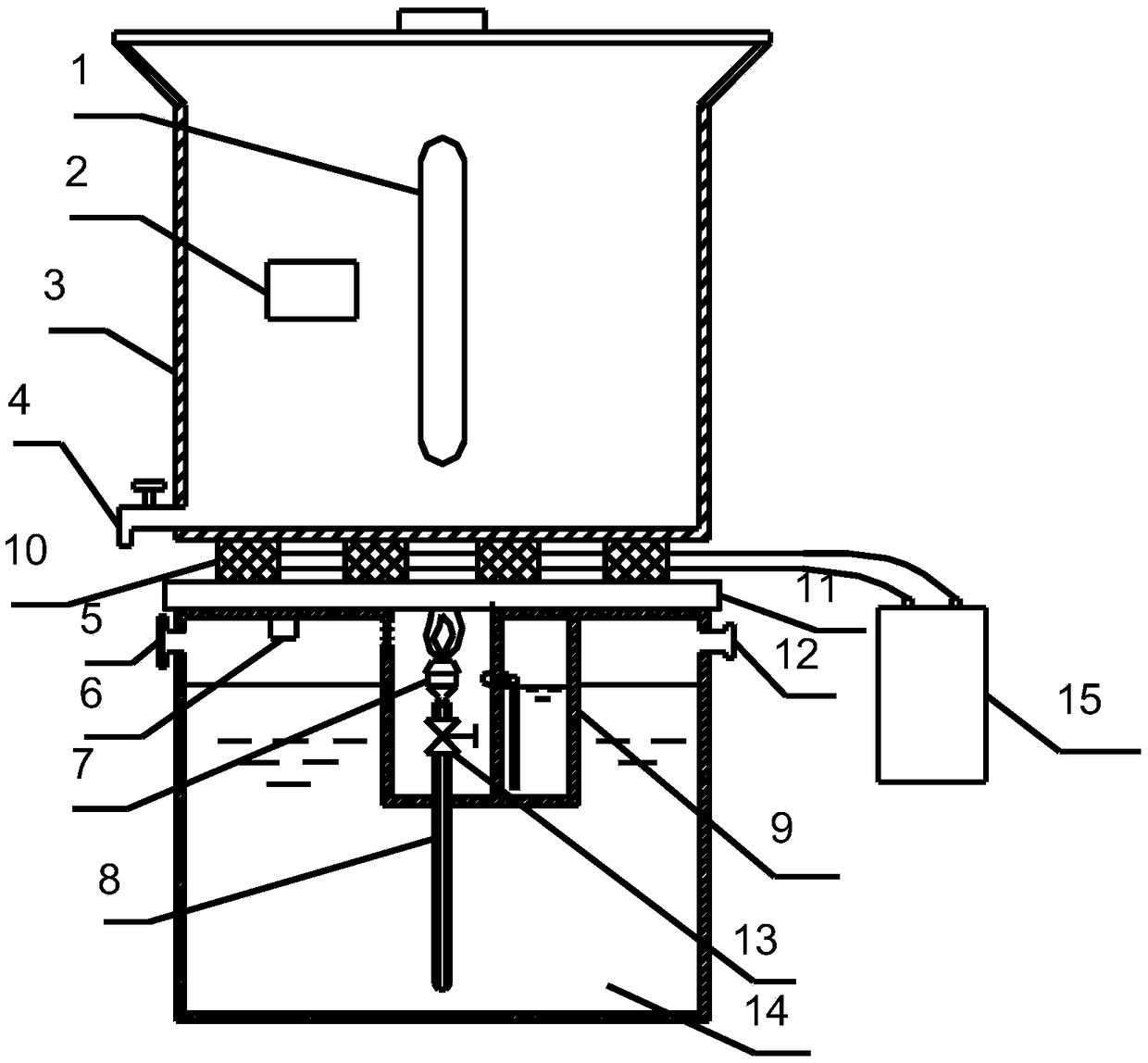

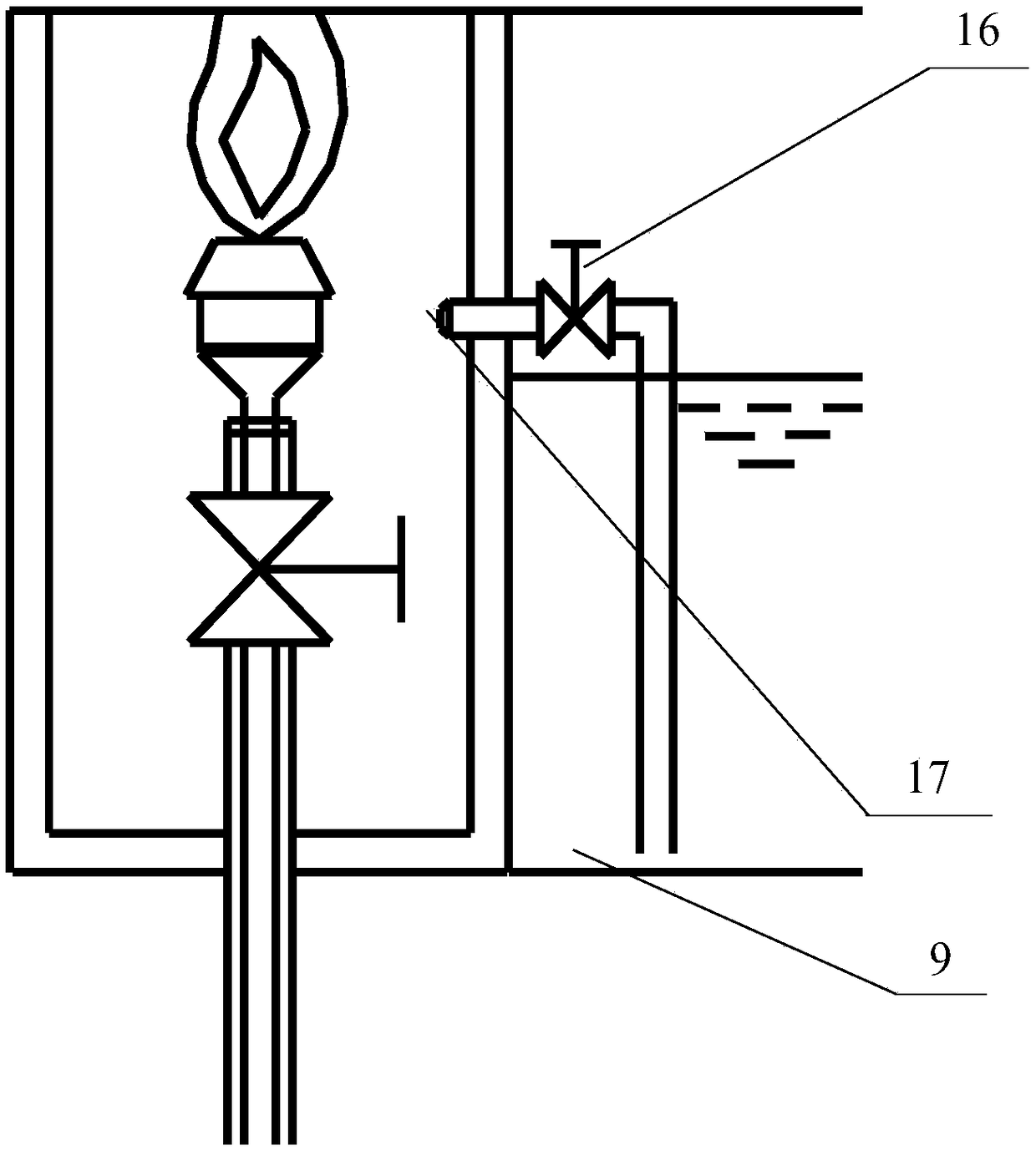

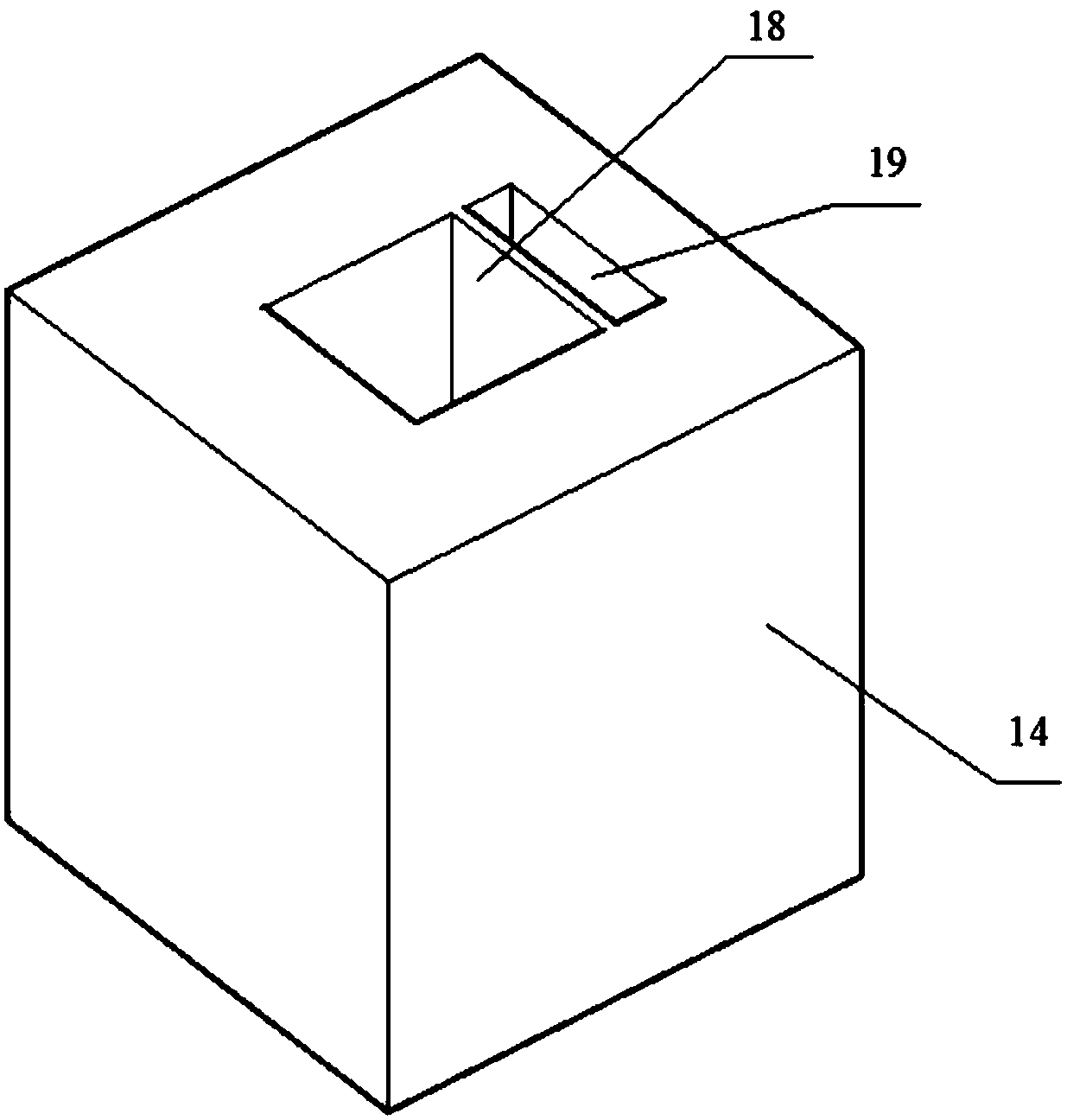

Quantitative constant-temperature agar pouring device

ActiveCN106622439ASolve the problem of solidificationAvoid troubleTemperatue controlLaboratory apparatusThermal insulationElectric heating

The invention relates to a quantitative constant-temperature agar pouring device. The quantitative constant-temperature agar pouring device is mainly applied to a biological or medical experiment. The quantitative constant-temperature agar pouring device comprises a liquid discharging switch, a quantifying valve, a plunger, a one-way valve, a sample feeding port, a bottle cover, an insulating layer, a storage bottle, a plunger cavity, a return spring, an inlet pipe, a fixing groove, a partition board, electric heating plates, a charging interface, a storage battery, a storage battery switch, a control circuit, a temperature sensor, a temperature display, a control cabinet, a sample feeding table, a constant-temperature water bath, a vent hole and an outlet pipe. The storage bottle with agar is put into the small charged constant-temperature water bath for thermal insulation, and during operation, the quantitative constant-temperature agar pouring device can be placed on a sterile working platform, and through adjustment of the quantifying valve below the liquid discharging switch, the agar pouring volume is controlled to quantitatively pour the constant-temperature agar so as to meet requirements of a pouring culture method, bacterium-containing agar plate preparation and other experiments on sterile operation as well as precise control over the agar pouring volume and the temperature. The quantitative constant-temperature agar pouring device is convenient to move, easy and safe to operate and low in cost, and has relatively high popularization and application values and very strong creativity.

Owner:ANHUI UNIV OF SCI & TECH

Drum-based high-intensity magnetic machine for steel slag and magnetic separation method

The invention provides a drum-based high-intensity magnetic machine for steel slag and a magnetic separation method. The machine comprises a case as well as a power input shaft and a roller which aremounted on the case, the power input shaft is fixedly connected with a driving drum, and an end part is connected with a speed adjusting motor; the roller is fixedly connected with a driven drum, a magnetic roll is mounted in the roller, and a composite magnetic system composed of a hard magnetic material is arranged on the magnetic roll; a belt surrounds the driving drum and the driven drum. Scrap iron in the steel slag is separated by magnetic overturn, magnetic stirring, gravity and centrifugal force, and the drum-based high-intensity magnetic machine and the magnetic separation method havethe advantages of being efficient, energy-saving, environmentally friendly and the like.

Owner:南京芬钢环保科技有限公司

Solid water ball silicon composite fertilizer and preparation process

InactiveCN102649648ASolve the problem of solidificationImprove germination rateFertilizer mixturesSoil sciencePotassium silicate

The invention provides a solid water ball silicon composite fertilizer, and also discloses a preparation process of the composite fertilizer. Potash water glass of potassium silicate is used as a base material, urea and sugar are mixed and added to be dissolved into solution dilutedly, and then the mixture and diluted phosphoric acid are prepared into the fertilizer through a nozzle by using an air granulation method. The fertilizer is a neutral slow release fertilizer; the solid water ball contains more than 80 percent of water; the fertilizer can be fed together with seeds during mechanical seeding; the effects of resisting against drought in spring and improving the rate of emergence can be achieved, and the fertilizer is convenient to use; and the problem of solidification of the silicon composite fertilizer is solved and the defect of influence on crop growth due to over high alkalinity of the conventional liquid silicon fertilizer is overcome.

Owner:中国冶金矿业长春矿产资源开发有限公司

Kitchen waste oil-water separation device

PendingCN109368895AImprove the separation effectLow kinematic viscosityWater treatment parameter controlFatty/oily/floating substances removal devicesInductorElectromagnetic induction

The invention discloses a kitchen waste oil-water separation device. The device comprises a machine body, wherein a feeding hole is formed in the upper end of the machine body, a water outlet pipe andan oil outlet pipe are arranged at the lower end of the machine body, a first-stage filtering plate, a second-stage filtering plate, a stirrer, a heating system, an oil-water mixture discharging pipeand a separation tank are sequentially arranged in the machine body from top to bottom, an electromagnetic inductor is further arranged at the upper part of the machine body, and the heating device is provided with a temperature control device. The first-stage filtering plate and the second-stage filtering plate have different sizes, the amount of swill entering the device is controlled by virtueof the electromagnetic inductor, and heating and stirring are carried out, so that the kinematic viscosity is reduced, and the oil-water separation degree is increased. By arranging a density sensorat the bottom of an oil-water separation tank, the oil-water separation is realized through the change of the density, the density is accurately measured, and the separation effect is good.

Owner:宁夏宝塔石化煤化工研究院有限公司

Essential oil added type skin care product

ActiveCN102600056BPromote absorptionImprove absorption rateCosmetic preparationsToilet preparationsLiquid productMedicine

The invention provides an essential oil added type skin care product which is prepared from the following raw materials in percent by weight: 15-20 percent of lavender essential oil, 1-5 percent of sweet orange essential oil, 1-2 percent of rose flower essential oil, 2-4 percent of clary sage essential oil, 3-5 percent of rosemary essential oil, 2-4 percent of chamomile essential oil, 1-2 percentof arabian Jessamine essential oil, 10-15 percent of vitamin E and the balance of jojoba oil. According to the invention, the raw materials are mixed, and are subjected to ultrasonic oscillation to obtain a uniform liquid product with small oil drop diameter, so that the essential oil added type skin care product is obtained. The essential oil added type skin care product provided by the invention has the advantages of little irritation, good permeability and capability of remarkably improving the sub-health state of the skin within a short time to recover the skin health from inside to outside.

Owner:GUANGZHOU FRASLANE COSMETIC

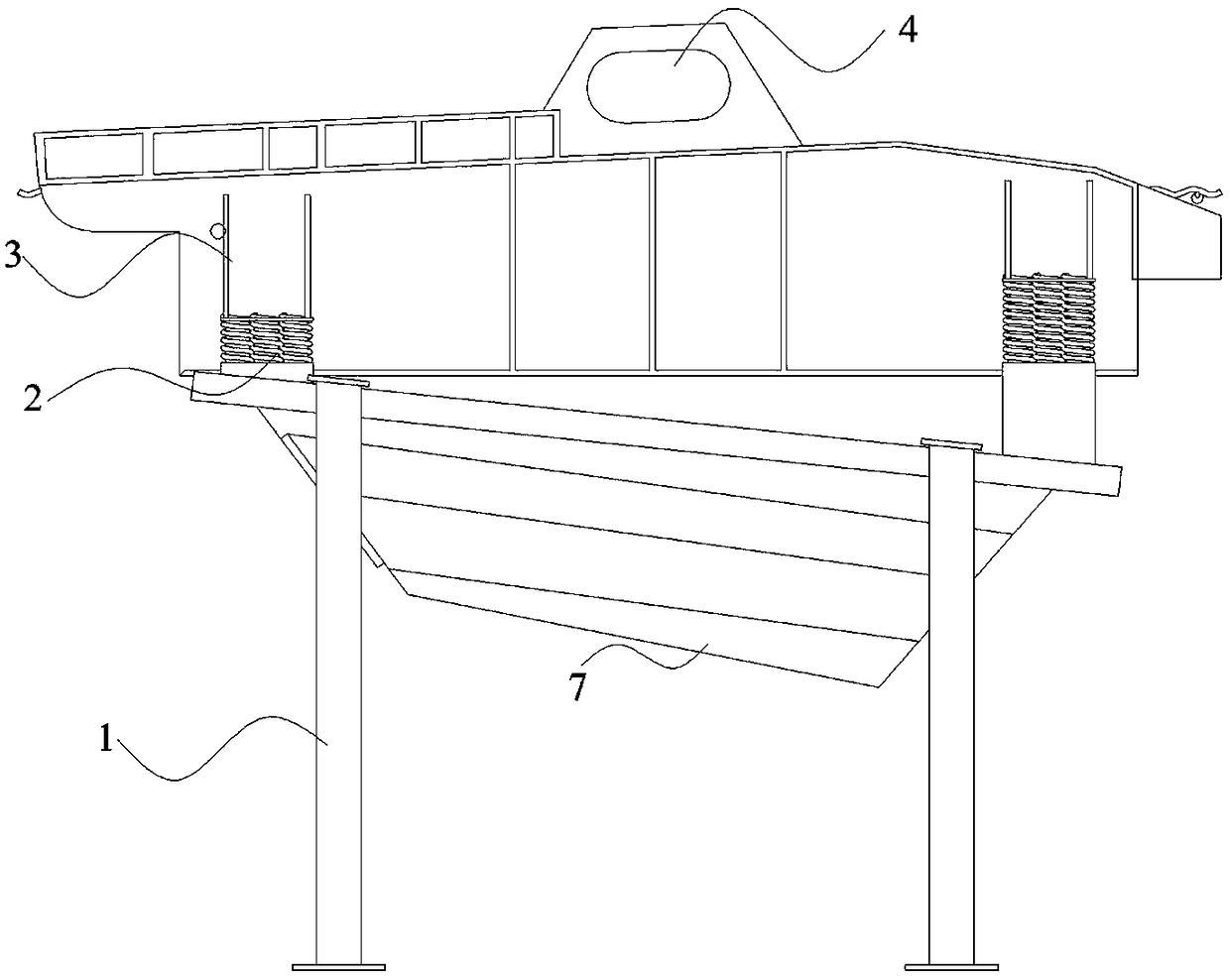

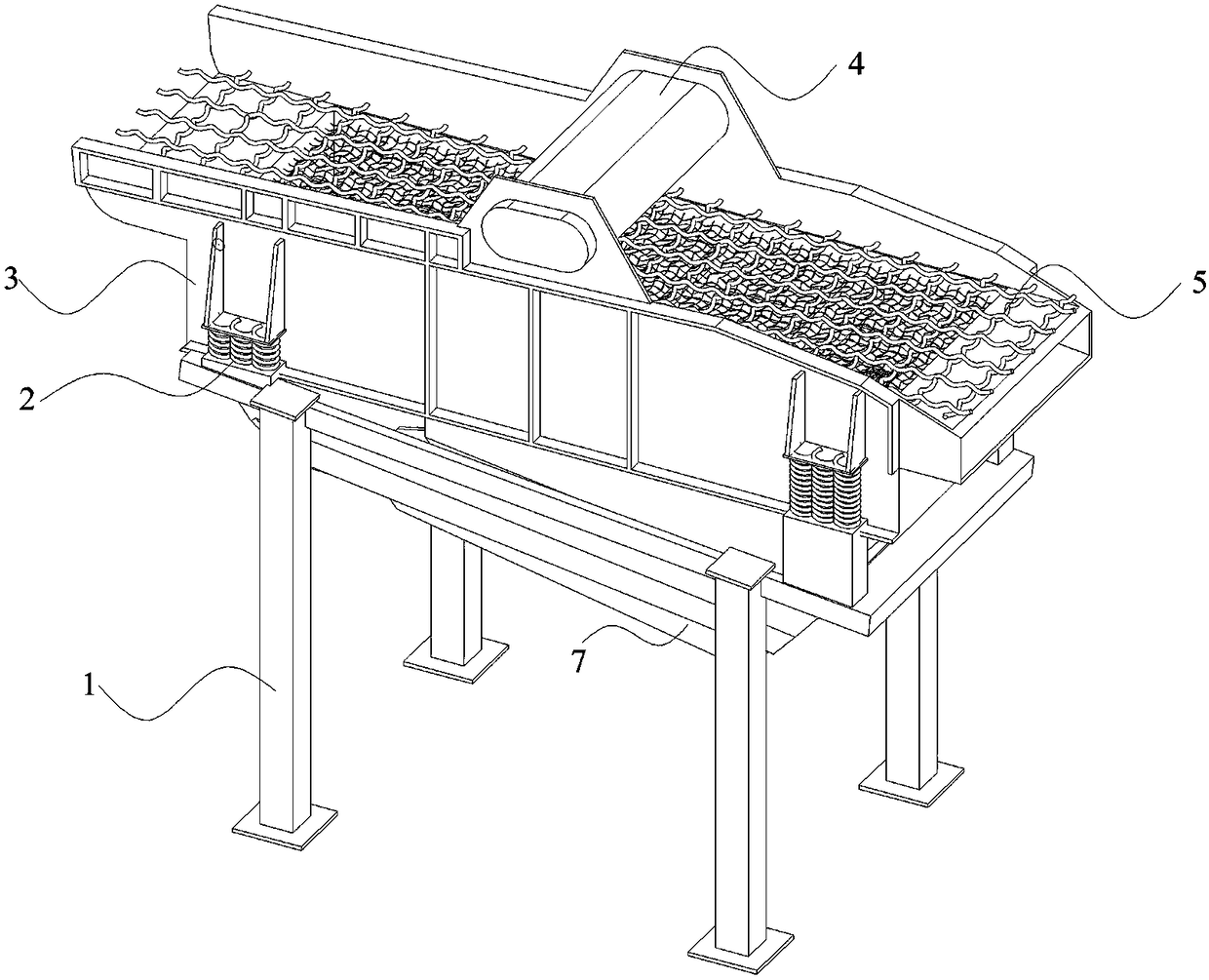

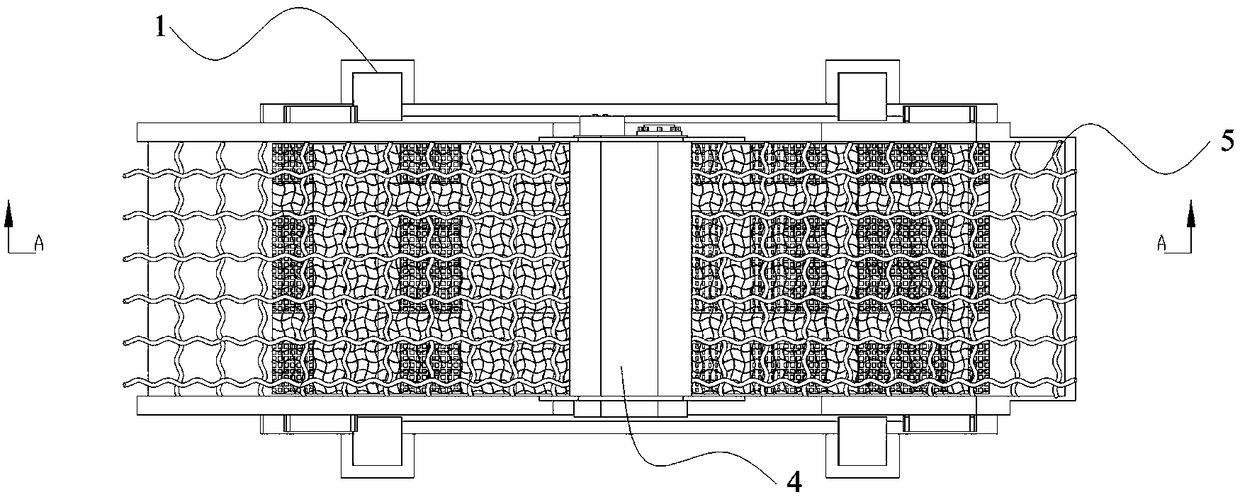

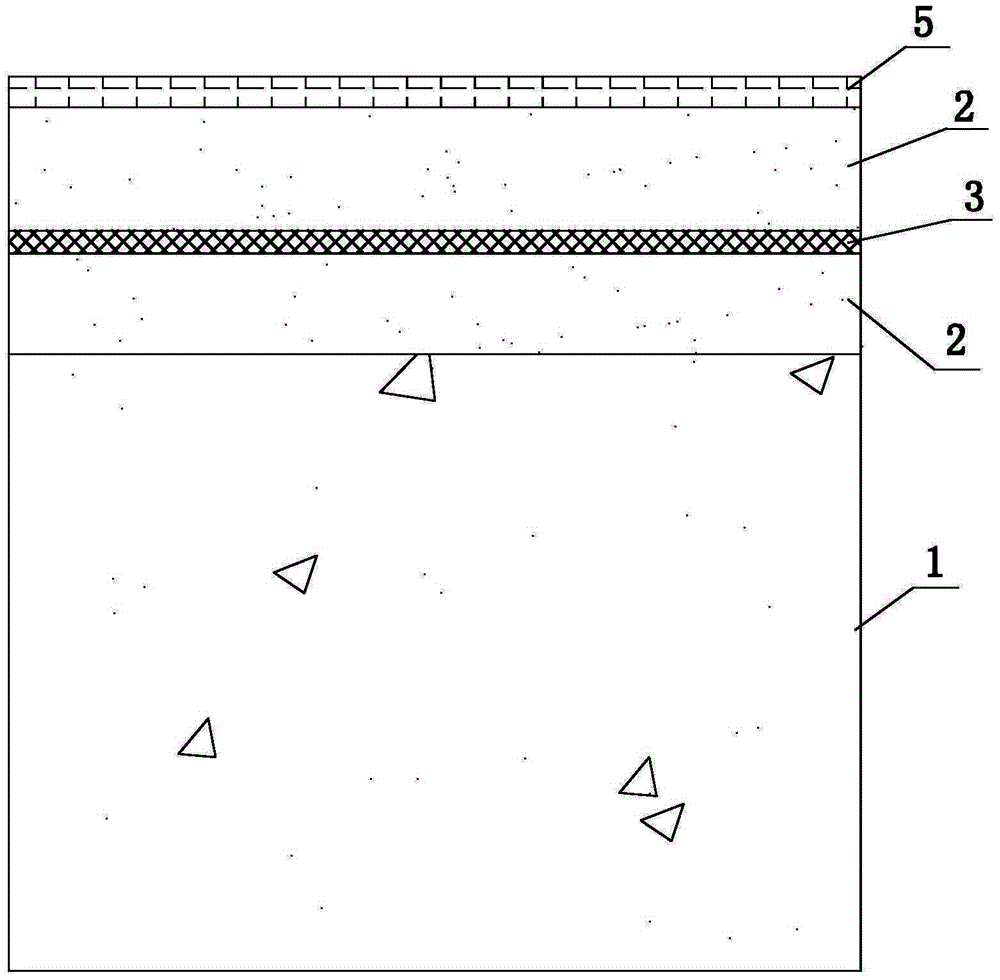

Horizontal vibration screen of steel slag and triple screening method

PendingCN109465186ARealize multi-stage screeningMulti-stage screening adaptationSievingScreeningSlagScreening method

The invention provides a horizontal vibration screen of steel slag and a triple screening method. The device comprises a frame and a vibration screen, wherein a discharging bin is arranged on the frame; the vibration screen is supported at the top end of the frame through support springs; a vibration exciter is fixedly mounted on the vibration screen; a top screen mesh and a middle screen mesh aremounted in the vibration screen; the middle screen mesh is supported on the top of the discharging bin; an oblique outlet opening is formed in the bottom of the discharging bin; an oblique conveyingbelt is arranged under the output opening. The method is characterized by screening the steel slag into three particle sizes; materials with size being greater than 60mm are screened on the top screenmesh; materials with size of 10-60mm are screened from remaining materials by the middle screen mesh; materials with size being smaller than 10mm fall into the discharging bin; the oblique conveyingbelt arranged at the bottom of the discharging bin is used for carrying the materials away. The overall process arrangement achieves the characteristics of high efficiency, energy economization and environment friendliness; the problem of coagulation of scrap iron in the tailing slag is also mainly solved; meanwhile, the horizontal vibration screen is high in reliability and convenient in on-sitemaintenance.

Owner:南京芬钢环保科技有限公司

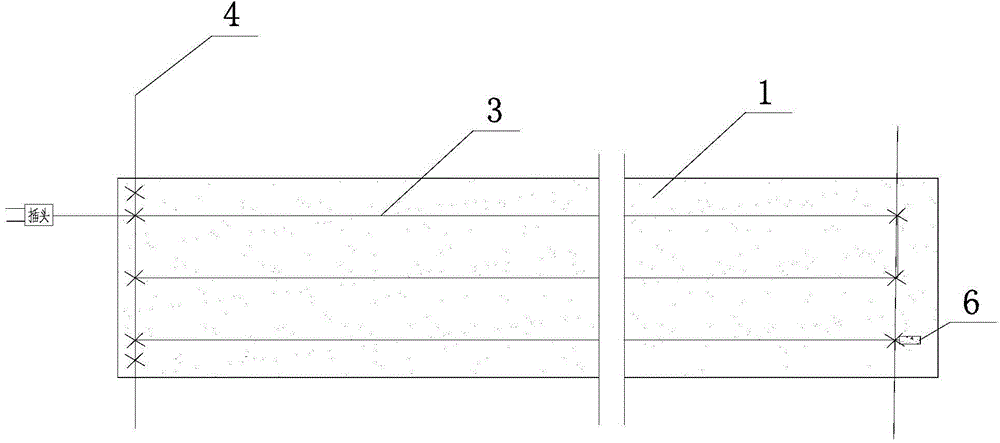

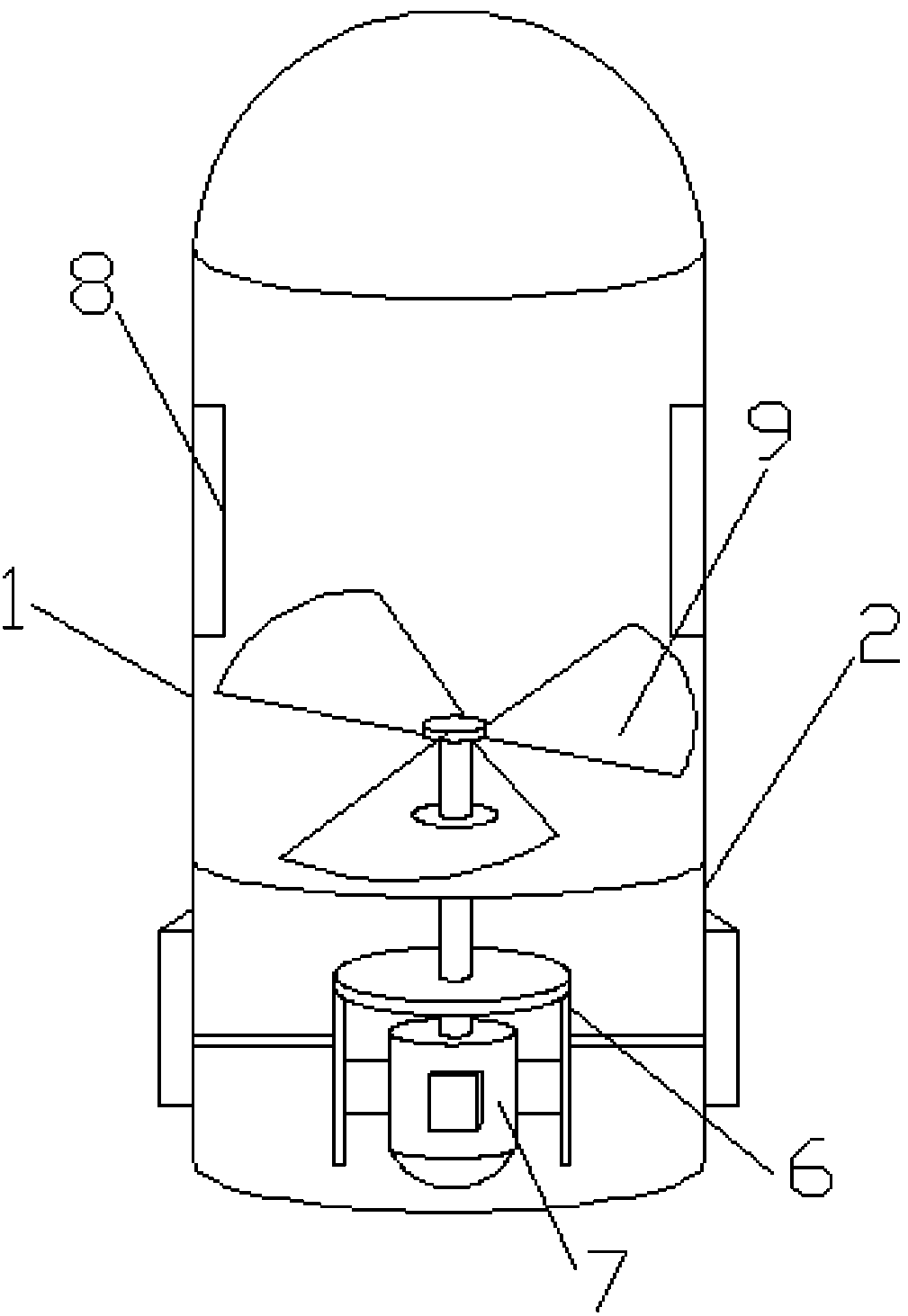

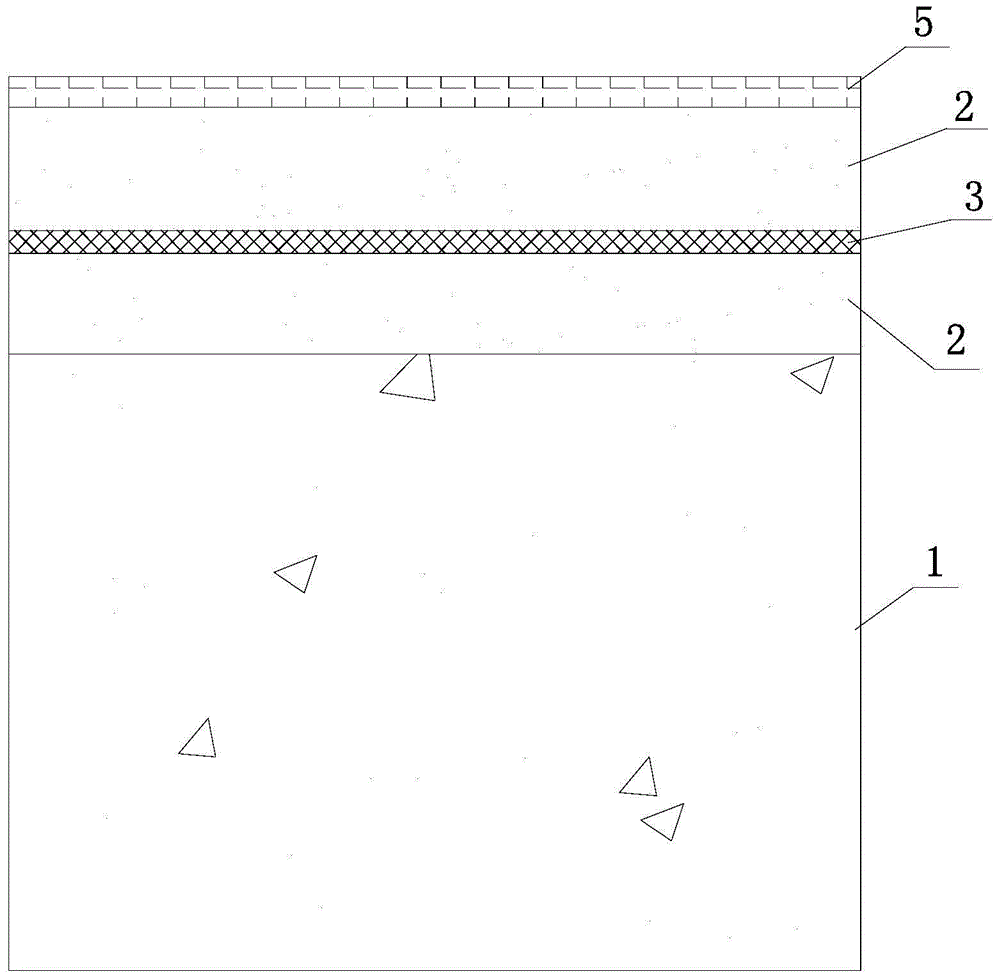

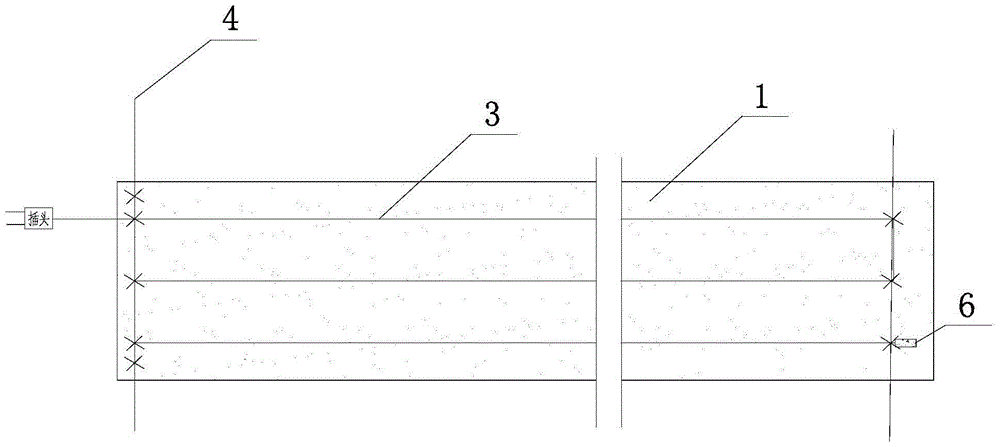

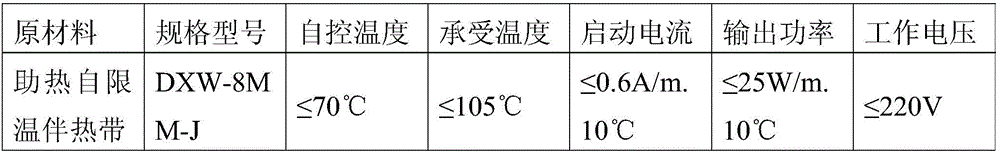

Hidden-buried electrical tracing floor tile paving construction method

ActiveCN104831898AAccelerate solidificationFast constructionLighting and heating apparatusElectric heating systemCondensation processResource consumption

The invention relates to a hidden-buried electrical tracing floor tile paving construction method. The hidden-buried electrical tracing floor tile paving construction method sequentially includes the following steps of construction preparation, computer pre-layout, basic layer treatment, elevation locating, line snapping, electrical tracing belt fixation, leveling layer paving, electrical tracing coil pulling, electrical tracing electrification, felt paving, joint pointing and joint wiping. An electric tracing belt is used for directly heating the bottom of a floor tile, the condensation process of cement is accelerated, the construction speed is increased, and the problem that construction cement is solidified indoors in winter is solved. The problems that resource consumption is large and pollution is severe when coal and gas are used for heating indoor space in the prior art is avoided.

Owner:TIANJIN TIANYI CONSTR GRP

Starch-free mushroom sausage and processing method thereof

InactiveCN103478701BReduce dissolutionLighten the colorFood ingredient as gelling agentFood processesBiotechnologyFlavor

The invention belongs to the technical field of edible fungi processing, and particularly relates to starch-free mushroom sausage and a processing method thereof. The starch-free mushroom sausage includes the following components in parts by weight: 20-60 parts of mashed mushrooms, 0-30 parts of mushroom grains, 2-10 parts of soy protein, 0.5-5 parts of carrageenan, 0.5-4 parts of konjac glucomannan, 1-4 parts of dietary fibers, 0.3-3 parts of spices, 10-40 parts of a mushroom cooling bath, 1.5-2.5 parts of table salt, 2-10 parts of vegetable oil, appropriate amount of an antioxidant and appropriate amount of a preservative. According to the invention, the problems of waste water emission during rehydration of dried mushrooms or mushroom stems and additive-free solidification of the soy protein, and the product has special flavor of mushrooms and similar tough and chewy bite feeling, and has the characteristics of enriched dietary fibers, and the realization of no meat or starch additives.

Owner:HENAN XIANGYU FOOD

Coating concretion preventing coating barrel

InactiveCN108466748ASolve the problem of solidificationSolve precipitationShock-sensitive articlesInternal fittingsMotor driveElectric machinery

The invention discloses a coating concretion preventing coating barrel which is formed by a material barrel and a power box. The material barrel is located above a power box body, a sealing cover is arranged at the top of the material barrel, a control plate and a discharging opening are arranged on a barrel wall of the material barrel, a fixing block and a motor control box are arranged outside the power box, a fixing support and a motor are arranged inside the power box, the fixing support is formed by a limiting disc and a support body, the limiting disc and the support body are fixedly welded, fixed connecting rods are arranged at the two ends of the support body, one end of each fixed connecting rod is fixedly connected with the support body, and the other end of each fixed connectingrod is fixedly connected with the inner wall of the power box. Through the design of a heater and a stirring blade, the conditions of concretion and sedimentation are effectively avoided; the motor drives the stirring blade to achieve stir at constant speed, coating inside the material barrel keeps moving, and the problem of sedimentation is solved; and if it is cold, the heater can provide a certain temperature for the interior of the material barrel, and the phenomenon that concretion is caused by cold weather is avoided.

Owner:FOSHAN HUIZHONG SENTAI TECH CO LTD

A preheating chemical regenerative diesel engine

ActiveCN105604694BReduce heat dissipationImprove efficiencyInternal combustion piston enginesThermal treatment of fuelExternal combustion engineFuel tank

The invention discloses a preheating-type chemical regenerative diesel engine, and relates to a diesel engine, and in particular to the preheating-type chemical regenerative diesel engine. By using the preheating-type chemical regenerative diesel engine, the problems that an existing diesel engine is lower in efficiency and higher in oil consumption are solved. An oil outlet of an oil tank of the preheating-type chemical regenerative diesel engine is connected with a supercharge pump through a flow regulating valve; the supercharge pump is connected with an inter cooler; the inter cooler is connected with an air cylinder through an air inlet pipe; a piston is arranged in the air cylinder; a cooling passage is arranged on the outer side wall of the air cylinder; a ceramic thermal insulating layer is mounted on the cooling passage in a sleeving manner; the inter cooler is connected with a diesel oil-tail gas heat exchanger; the air cylinder is connected with an exhaust-driven gas turbine through an exhaust pipe; the exhaust-driven gas turbine is connected with the diesel oil-tail gas heat exchanger; the air cylinder is connected with a switching valve; the switching valve is connected with the air cylinder through a gaseous fuel nozzle and a liquid fuel nozzle; the supercharge pump is connected with the inter cooler. The preheating-type chemical regenerative diesel engine belongs to the field of internal combustion engines.

Owner:HARBIN INST OF TECH

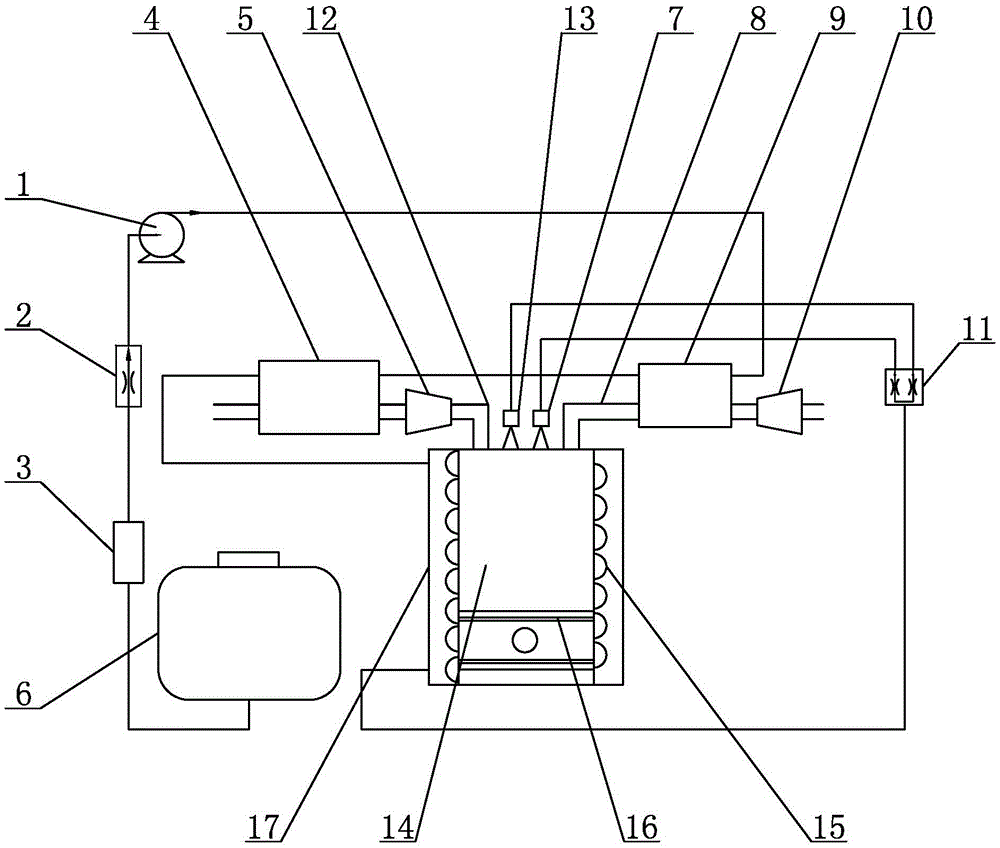

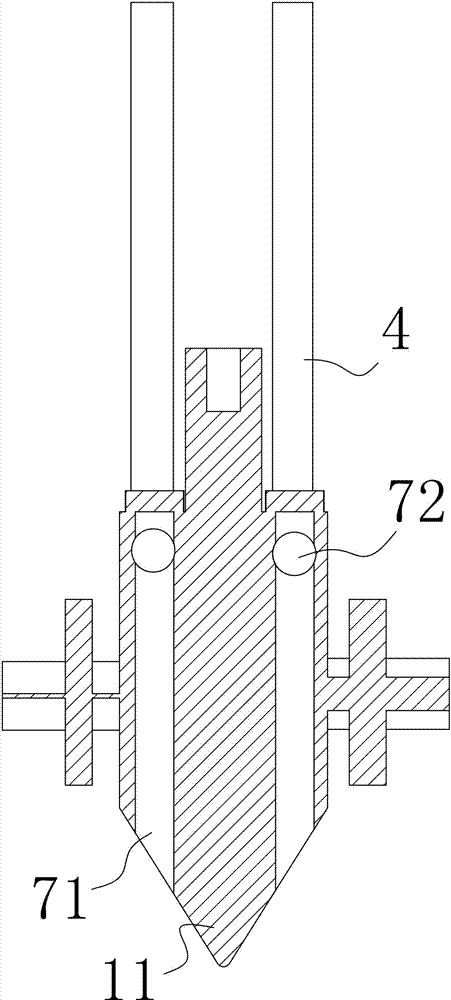

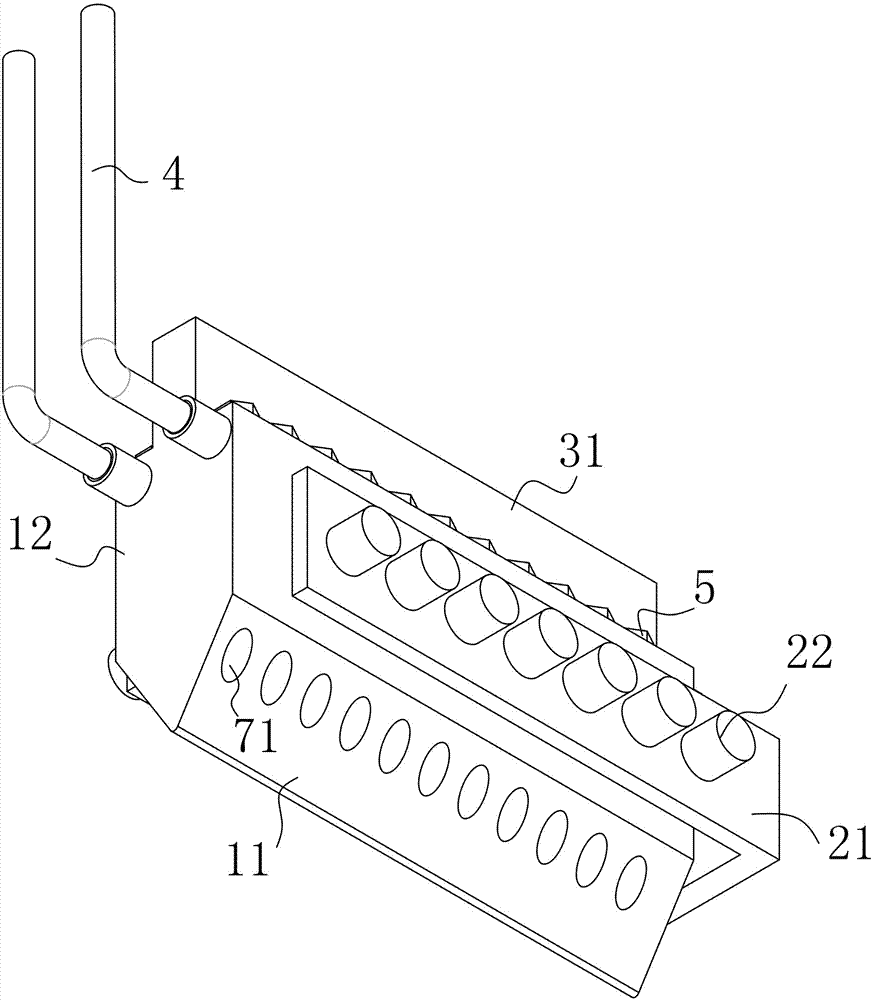

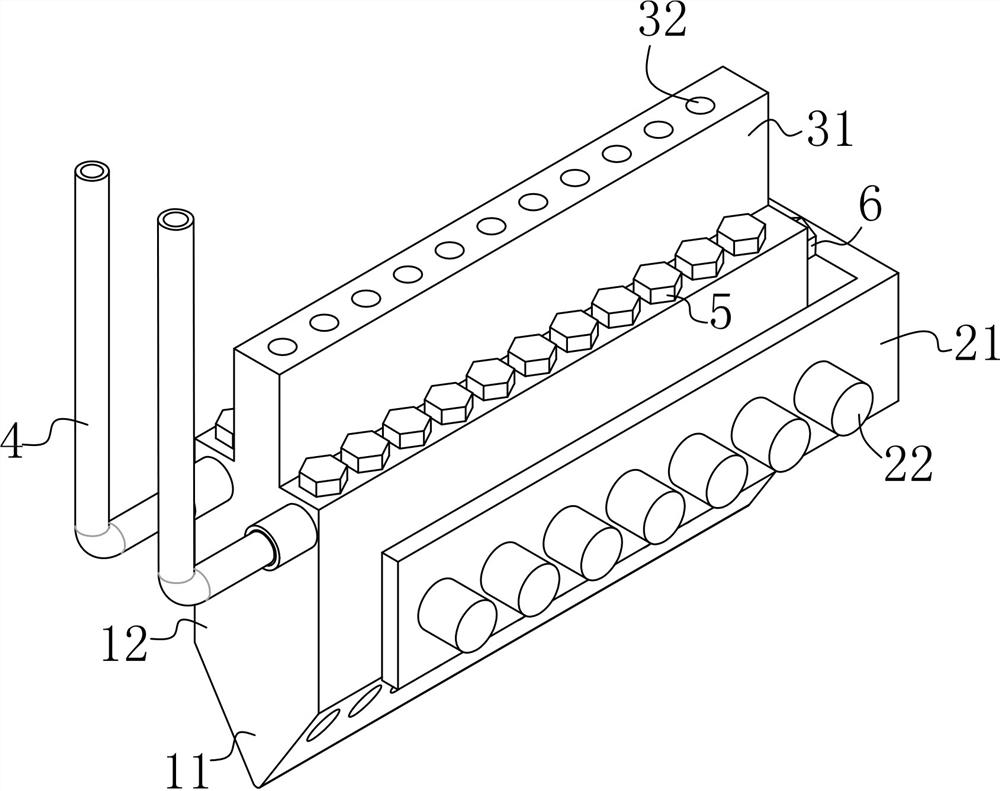

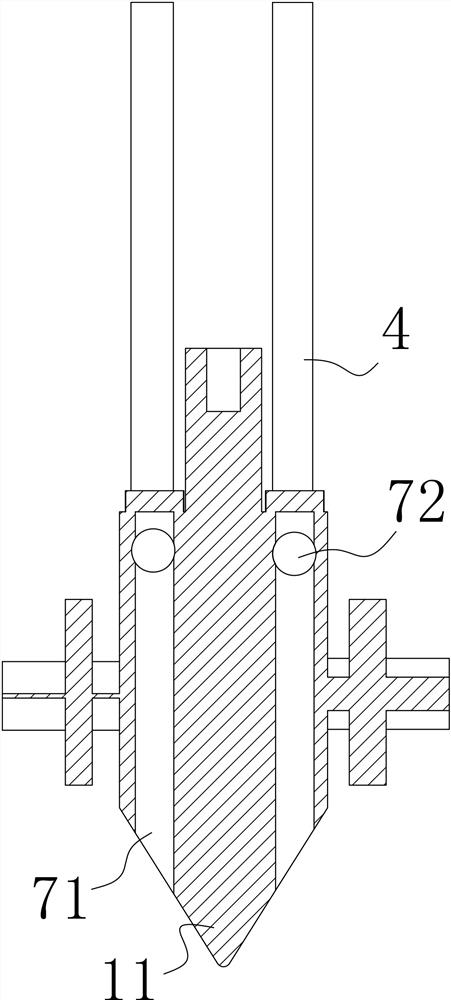

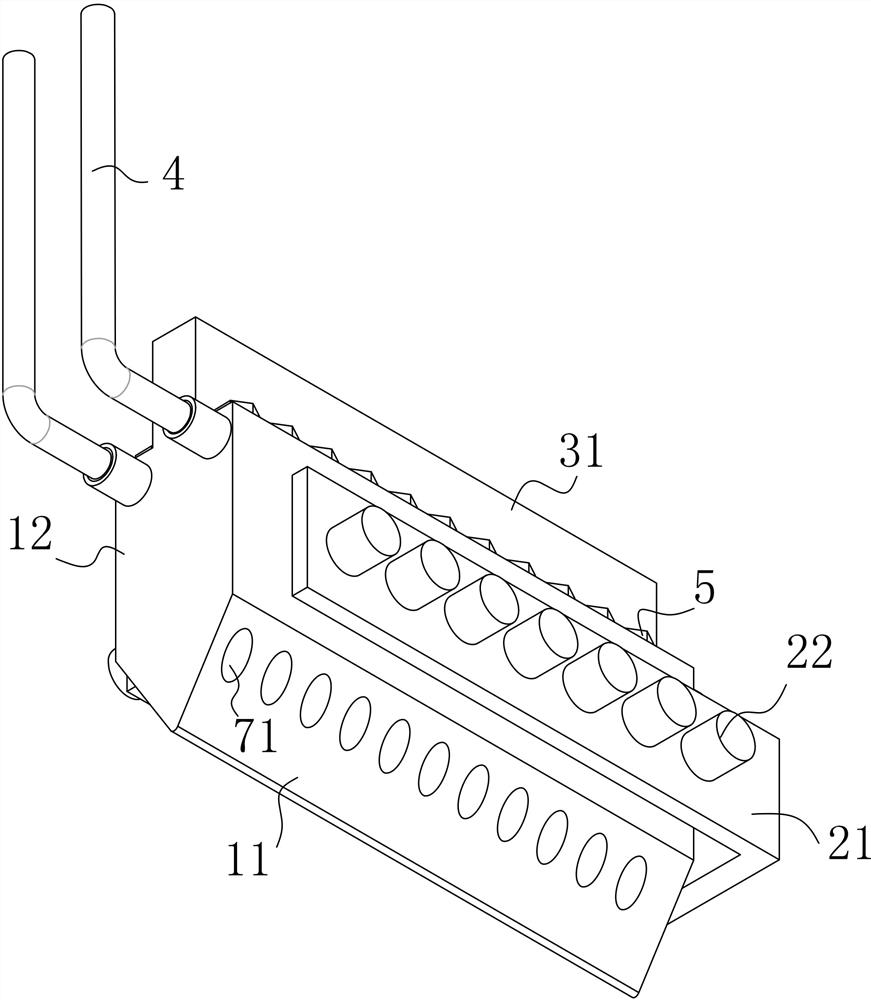

fpc pressure keeping machine

InactiveCN106993380BSolve the problem of harming the human bodySolve the cooling problemPrinted circuit assemblingEngineeringAtmosphere

Disclosed are a pressure holding machine for a flexible printed circuit (FPC). The machine comprises: a frame, a support board for placing an FPC, a downward pressing pneumatic cylinder provided on the frame, and a pressure holding head connected to a power output end of the downward pressing pneumatic cylinder. The pressure holding head comprises a main body. Multiple air suction channels (71) arranged in two rows and extending vertically are provided on the main body, and each of the air suction channels (71) has an air suction opening formed at a lower end thereof. Also provided are two parallel communication channels (72) extending in a horizontal direction, and each of the communication channels (72) passes through and is in communication with a corresponding row of the air suction channels (71). Each of the communication channels (72) has one end formed as an air discharge opening. Such pressure holding machine for an FPC solves the problems of a harmful gas being spread into the atmosphere and causing damage to health, heat dissipation of elements nearby the head, and potential melting of a non-melting portion.

Owner:贵州华旭光电技术有限公司

A kind of fpc pressure holding machine coated with wear-resistant material

ActiveCN108076593BSolve the problem of harming the human bodySolve the cooling problemPrinted circuit assemblingNon-linear opticsEngineeringMachine

Disclosed is an FPC pressure-maintaining device coated with a wear-resistant material, comprising a machine frame, and a placement plate for placing an FPC, wherein the machine frame is provided with a downward pressure cylinder, a power output end of the downward pressure cylinder is connected to a pressure-maintaining pressure head, and the pressure-maintaining pressure head comprises a pressure head body. Providing multiple aspiration holes solves the problem of harmful gases dispersed in the air harming the human body, solves the problem of heat dispersion of adjacent elements, and solves the problem of solidifying non-molten parts.

Owner:DONGGUAN HEAN ELECTROMECHANICAL CO LTD

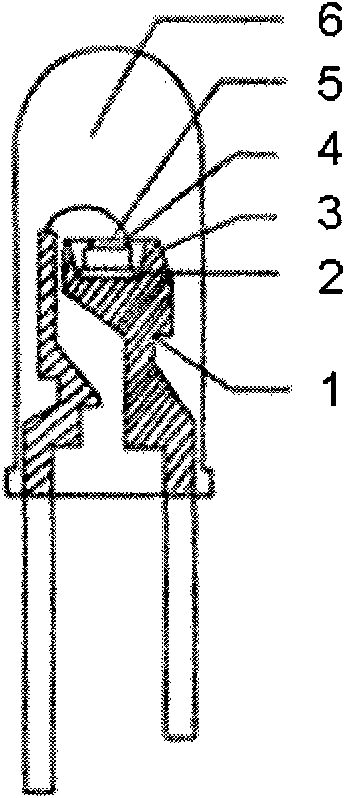

Light emitting diode and preparation method thereof

InactiveCN101916814BEvenly dispersedSolve precipitationSemiconductor devicesAcrylic resinUltraviolet lights

The invention discloses a light emitting diode. The light emitting diode at least comprises a bracket, an LED chip and a luminescent layer on the LED chip. The light emitting diode is characterized in that: the luminescent layer is a mixed system of one or more kinds of fluorescent powder capable of emitting light of various colors and an adhesive needing curing by ultraviolet light; the adhesive raw materials comprise the following components: unsaturated polyester resin or acrylic acid resin, styrene and derivatives thereof, photo initiator, photosensitizer and additive. The luminescent layer solves the problems of colloid solidification and fluorescent powder precipitation in the process of coating the fluorescent powder, improves uniformity of the fluorescent powder on the chip, improves adhesive property of the luminescent layer and the chip and shortens the curing time of the luminescent layer at the same time.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

A quantitative constant temperature agar pourer

ActiveCN106622439BSolve the problem of solidificationImprove experimental efficiencyTemperatue controlLaboratory apparatusWater bathsThermal insulation

Owner:ANHUI UNIV OF SCI & TECH

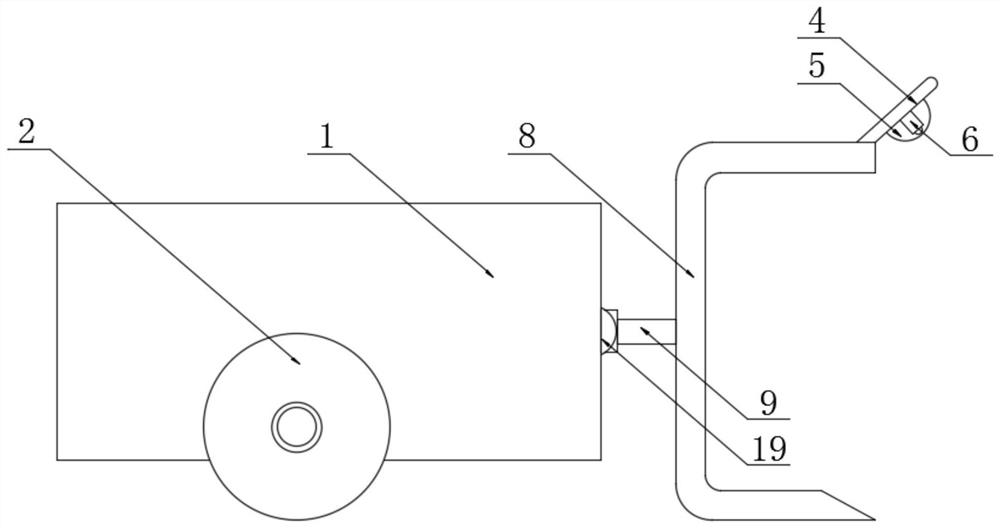

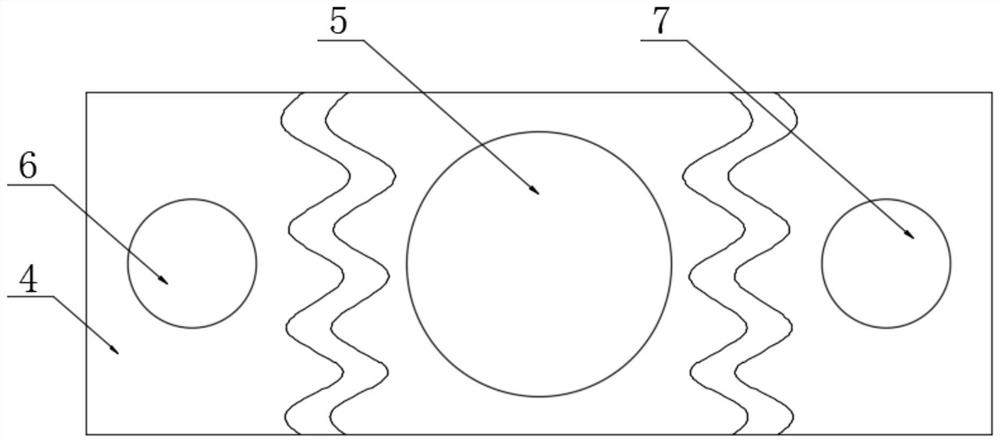

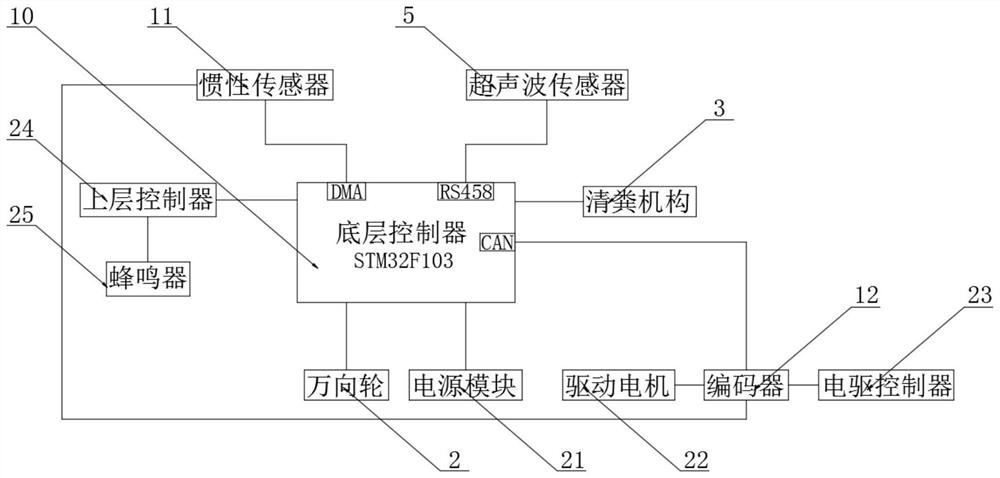

Excrement cleaning device for livestock farm

PendingCN114223550AReduce financial burdenGuaranteed data accuracyAnimal housingBird housingsAgricultural scienceOriginal data

The invention discloses an excrement cleaning device for a livestock farm, and particularly relates to the field of farms, the excrement cleaning device comprises a vehicle shell, universal wheels are arranged on the surfaces of the two sides of the vehicle shell, an excrement cleaning mechanism is arranged on one side of the vehicle shell, a fixing plate is arranged at the top of one end of the excrement cleaning mechanism, and an ultrasonic sensor is arranged at the bottom of the middle of the fixing plate. Compared with the prior art, by arranging the inertial sensor, a laser radar and excessive external sensors are omitted, the total cost is only 10% of the price of the laser radar carrying the navigation level, the economic burden of small and medium-sized farms is greatly reduced, and IMU data of the inertial sensor are obtained after matrix operation is conducted on original data. According to the method, data are obtained through Kalman filtering, the data precision is ensured, the obtained data is fused with the odometer for Kalman filtering, so that the navigation precision is clearly ensured, and the problem of extra cost caused by excessive dependence on an external positioning auxiliary technology in the past is solved.

Owner:SOUTH CHINA AGRI UNIV

Coagulant for wet spray material and its using method

The present invention provides a kind of coagulant for wet sprayed material and its usage. The coagulant consists of aluminum dihydrogen phosphate, magnesium chloride and water. The coagulant is used in the following steps: 1. feeding certain amount of coagulant into compressed air pipeline to atomize; and 2. conveying the atomized coagulant to nozzle for spraying together with wet sprayed material. Using the coagulant can solve the problem of densifying and solidifying wet sprayed material containing polyacylate or phosphate well, and make the sprayed material adhered well onto the sprayed surface and produce no crack during stoving. In addition, the coagulant has small added amount without affecting the use performance of the wet sprayed material.

Owner:BAOSHAN IRON & STEEL CO LTD

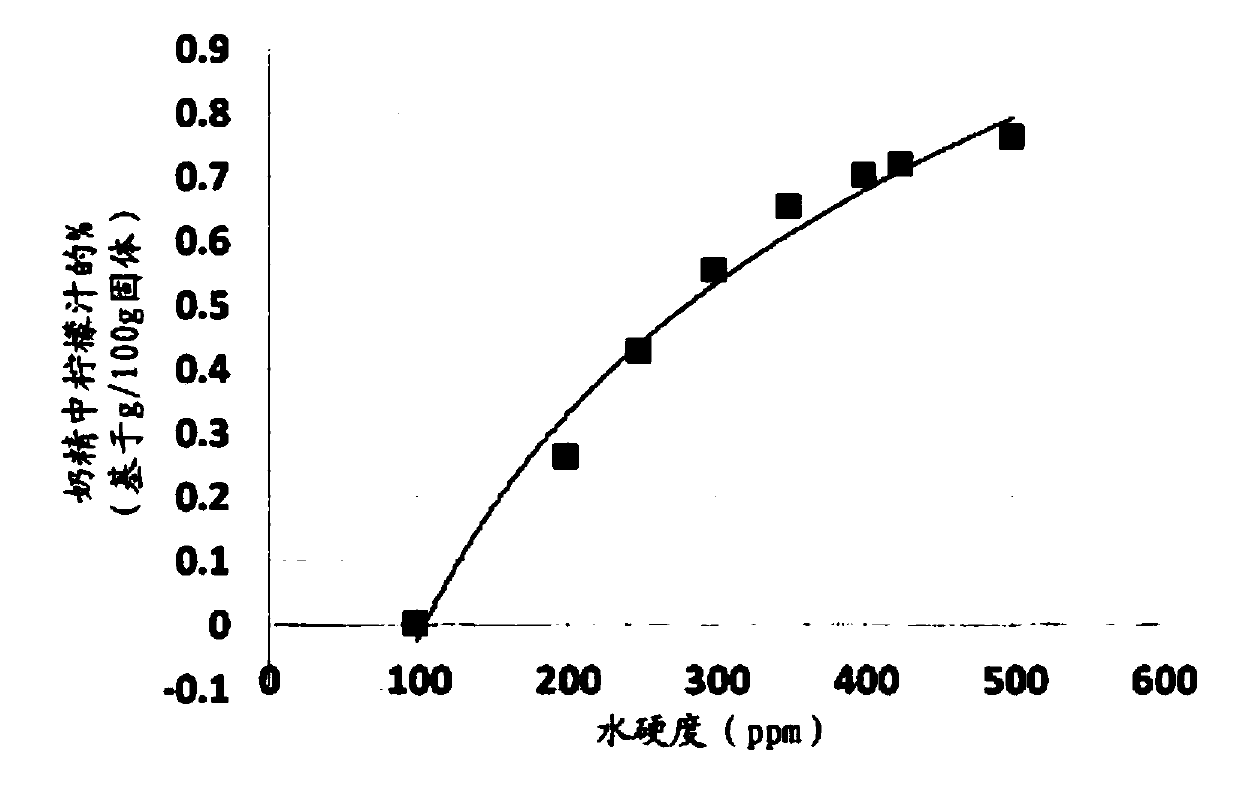

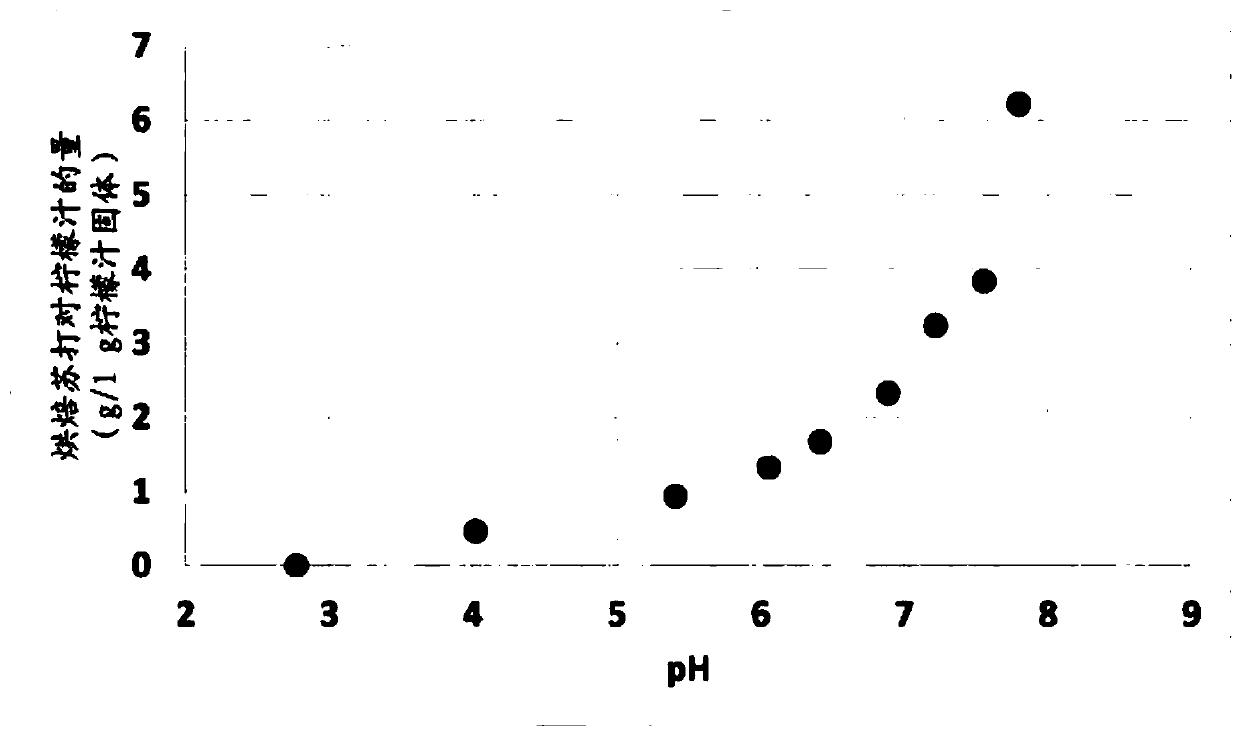

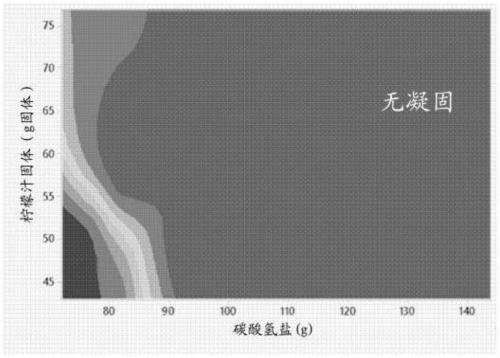

Natural creamer with high tolerance to acidity and minerals in beverage

PendingCN111065275AGood whitening effectGreat tasteCream substitutesMilk substitutesMouthfeelFruit juice

Natural Creamers for providing whitening and indulgent texture / mouthfeel of beverage and food products are provided. The creamers have long-term stability, high whitening capacity and a pleasant mouthfeel when added to beverage and food, while being free from artificial additives the creamers comprising plant oil and plant proteins, and being further characterized in that the creamers comprise baking soda and citrus fruit juice concentrate, wherein the citrus fruit juice concentrate comprises acid component comprising citric acid and malic acid.

Owner:NESTEC SA

Laying and pasting construction method of buried electric heating floor tiles

ActiveCN104831898BAccelerate solidificationFast constructionLighting and heating apparatusElectric heating systemCondensation processResource consumption

The invention relates to a hidden-buried electrical tracing floor tile paving construction method. The hidden-buried electrical tracing floor tile paving construction method sequentially includes the following steps of construction preparation, computer pre-layout, basic layer treatment, elevation locating, line snapping, electrical tracing belt fixation, leveling layer paving, electrical tracing coil pulling, electrical tracing electrification, felt paving, joint pointing and joint wiping. An electric tracing belt is used for directly heating the bottom of a floor tile, the condensation process of cement is accelerated, the construction speed is increased, and the problem that construction cement is solidified indoors in winter is solved. The problems that resource consumption is large and pollution is severe when coal and gas are used for heating indoor space in the prior art is avoided.

Owner:TIANJIN TIANYI CONSTR GRP

Soy protein vegetarian sausage and preparation method thereof

The invention belongs to the field of food processing and especially relates to a processing application of soybean protein isolate and a vegetarian soybean-protein roasted sausage. The vegetarian soybean-protein roasted sausage comprises the following ingredients: soybean protein isolate, tissue protein, vegetable oil, starch, salt, sugar, monosodium glutamate, spices, vegetarian Taiwan roasted-sausage essence, potassium sorbate, TG enzyme and monascorubin. According to the preparation method, the whole processing technology of the roasted-sausage product, especially the time for chopping and mixing, the order of material feeding as well as the process parameters including the temperature, the time and the like, are controlled; thus, the invention solves the problems of soybean-protein coagulation, vegetarian-sausage processing cost and popularization.

Owner:山东禹王生物技术有限公司

Preparation process of aluminium lining corundum oxide film

InactiveCN1138875CSolve the problem of solidificationSurface reaction electrolytic coatingCapacitanceElectrolysis

Aluminum material or aluminum foil for capacitor after being washed with deionized water is placed inside pressure pan with deionized water, and the pressure pan is heated to 210-250 deg.C at the temperature rise rate of 2-5 deg.C / min, maintained for 20-60 min, further heated to 400-450 deg.C at the rate of 20 deg.C / min, maintained for 2-6 min, cooled naturally to room temperature. The material taken from the pressure pan is washed with deionized water and stoved. The present invention makes it possible for developing solid electrolyte capacitor and may be used in interference-shielding circuit board, acoustic surface wave device, transparent medium, shielding and insulating layer for transformer so as to solve the solidification problem of integrated electroluminecent device.

Owner:XI AN JIAOTONG UNIV

A portable water production and power storage integrated device for high altitude areas

ActiveCN107395066BEasy to splitReduce volumeBatteries circuit arrangementsElectric powerElectricityAnti freezing

The invention discloses a water preparation and power storage integrated device used for a high-attitude area. The water preparation and power storage integrated device comprises a heating module, a power generation module and a water preparation module, wherein the heating module comprises a concave oil tank, a combustion device, a kerosene anti-freezing and pre-heating device and a flat plate hot pipe, a concave part of the concave oil tank is partitioned into a combustion region and an anti-freezing and pre-heating region, the combustion device is arranged on the combustion region, the kerosene anti-freezing and pre-heating device is arranged on the anti-freezing and pre-heating region, the flat plate hot pipe is arranged at the top of the concave oil tank, the water preparation module comprises a fresh water preparation tank, the power generation module comprises a temperature difference power generation device and a storage battery, the flat plate hot pipe and the fresh water preparation tank form two poles of large temperature difference of the temperature difference power generation device, and the temperature difference power generation device is arranged between the two poles of large temperature difference. By the device, the problem of kerosene anti-freezing and pre-heating of the high-attitude area is solved, portable fresh preparation can be achieved, temperature difference power generation also can be achieved by a low temperature of a polar region environment and a high temperature generated by kerosene combustion, so that the water and power utilization demand of expedition during scientific investigation in the field is satisfied.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com