Drum-based high-intensity magnetic machine for steel slag and magnetic separation method

A drum and steel slag technology, applied in the field of smelting slag treatment, can solve the problem that the treatment speed cannot meet the requirements, and achieve the effects of simple structure, reduced treatment cost and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

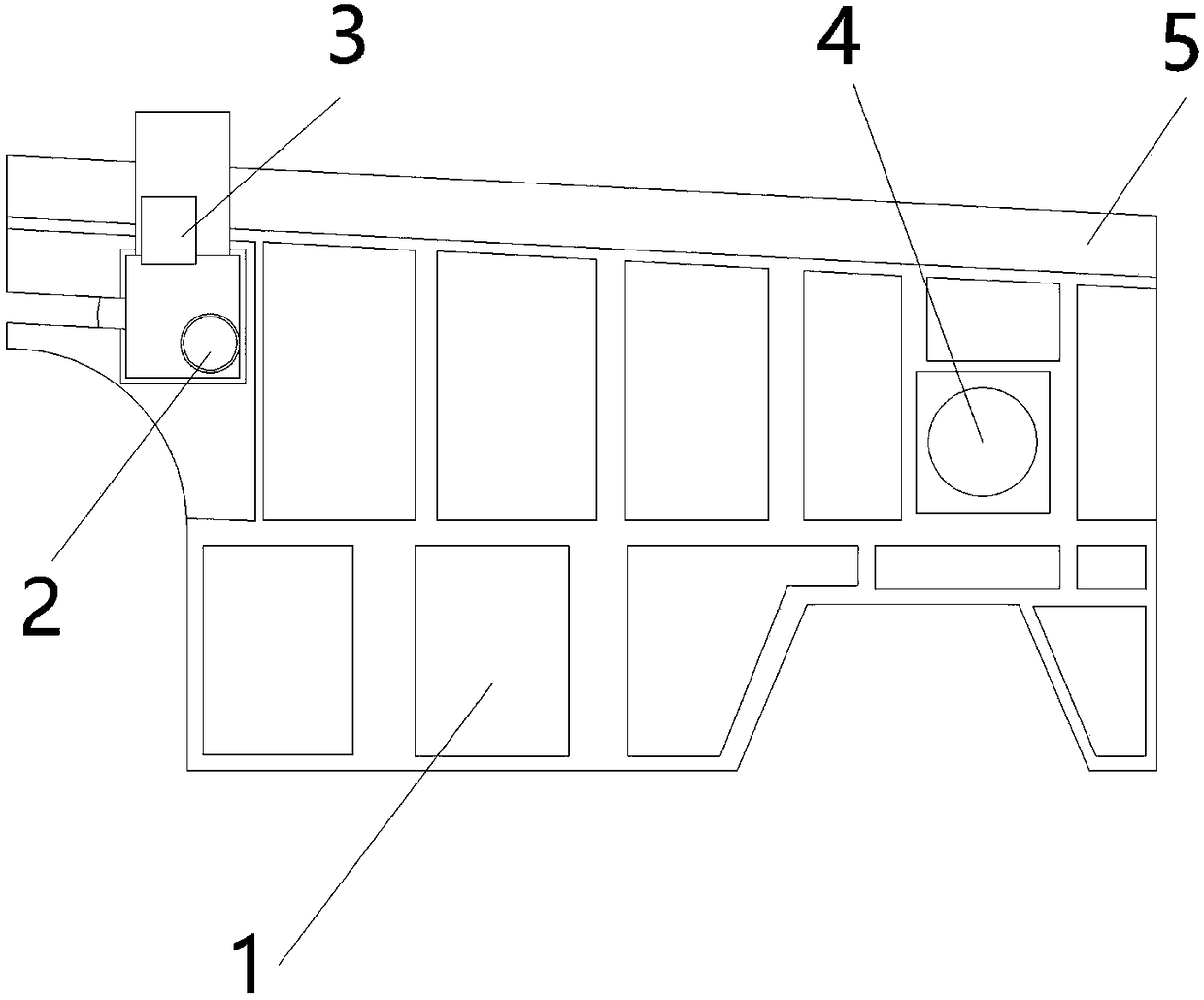

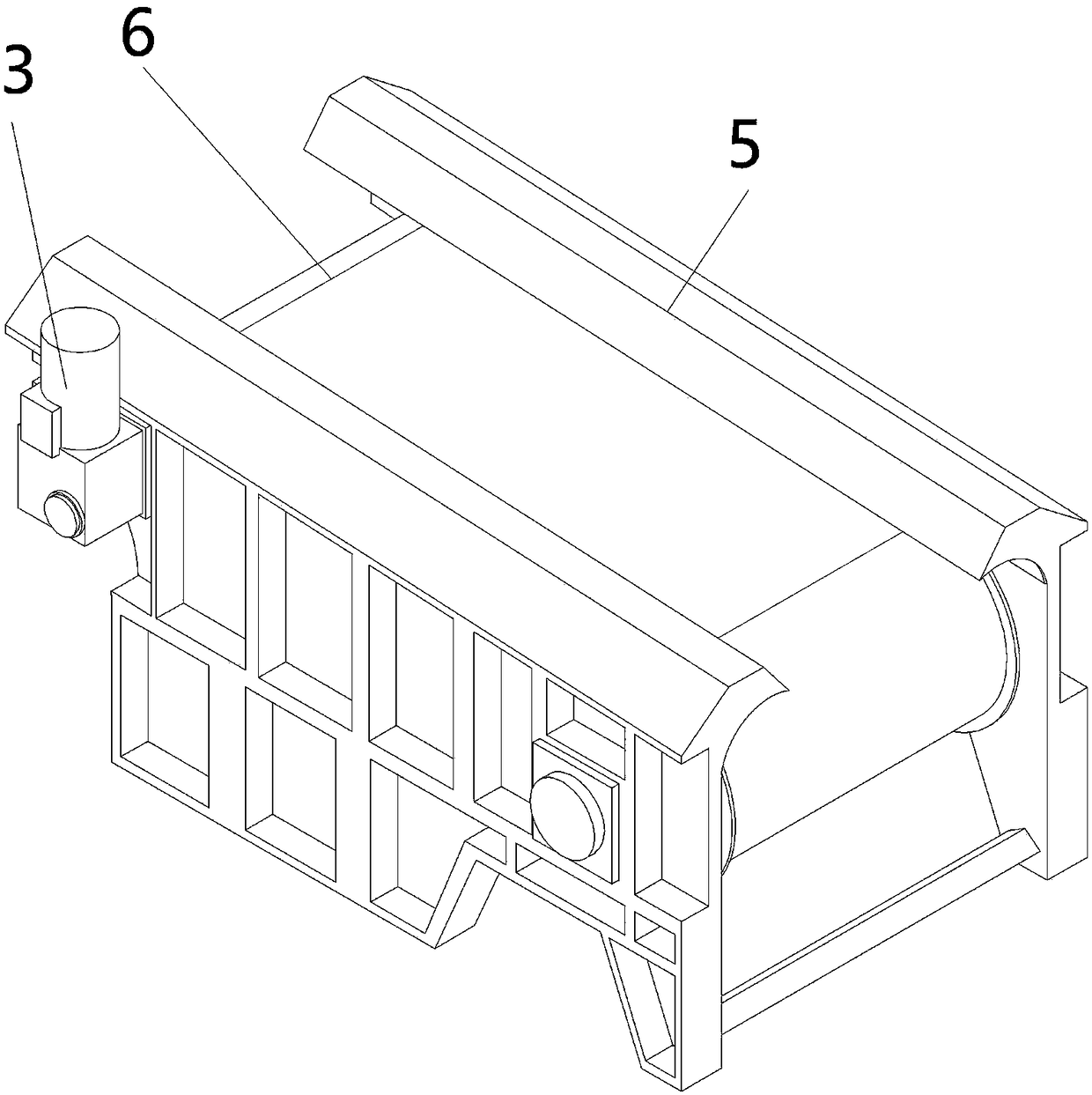

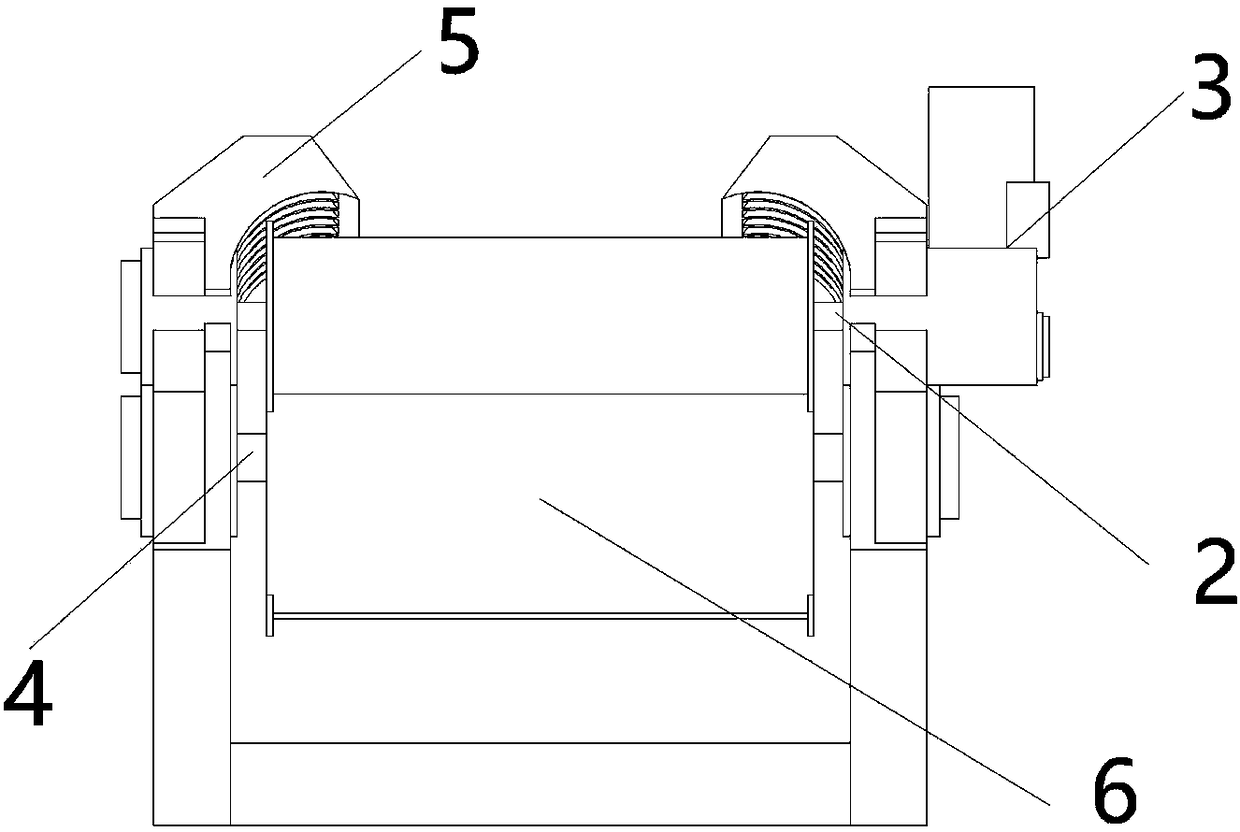

[0022] The steel slag drum belt magnetic separator of the present embodiment is as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the two vertical walls are connected by cross bars to form a cabinet 1, a baffle 5 is arranged on the top of the cabinet 1, and a power input shaft 2 and a roller 4 are installed in parallel inside, and the power input shaft 2 is connected to the speed regulating motor 3. The power input shaft 2 is fixedly connected with the driving roller 21 , the roller shaft 4 is fixedly connected with the driven roller 41 in the cabinet, and the magnetic roller 42 is installed in the driven roller 41 . The belt 6 is installed on the driving drum 21 and the driven drum 41 .

[0023] When in use, input hot stuffy steel slag with particle size of 10-200mm, the diameter of the driven drum is 1200mm, and the magnetic roller inside the drum is equipped with Bazier oxide permanent magnet, and its position can be adjusted. The diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com