fpc pressure keeping machine

A pressure-holding machine and indenter technology, applied in electrical components, printed circuit manufacturing, printed circuits, etc., can solve the problems of component damage, low yield, melting of non-melted parts, etc., to solve the problem of heat dissipation and solidification. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

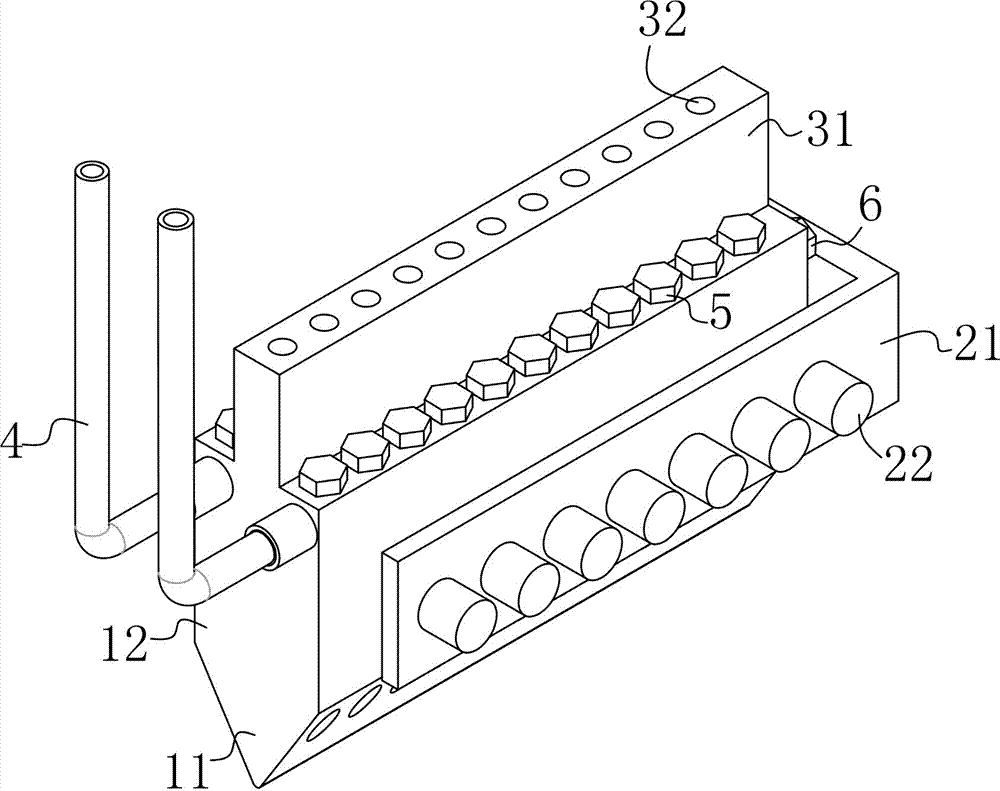

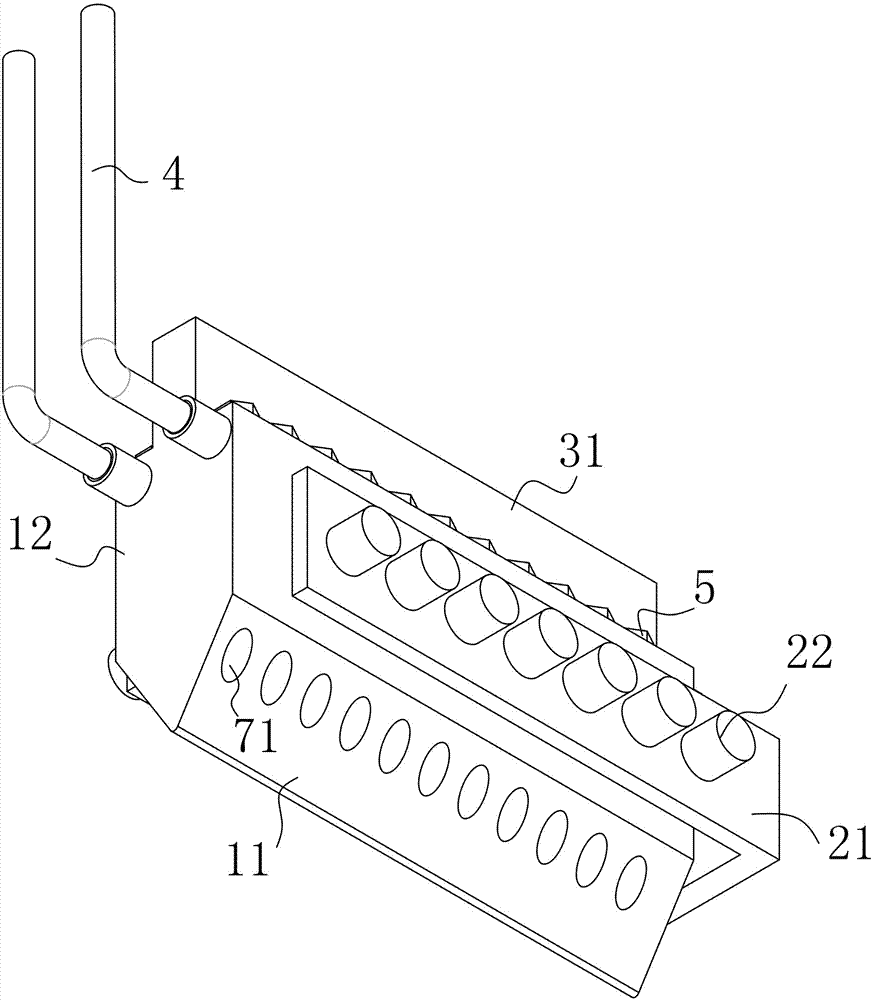

[0018] Such as Figure 1 to Figure 4 As shown, a kind of FPC pressure-holding machine described in this embodiment includes a frame and a shelf plate for placing FPC. .

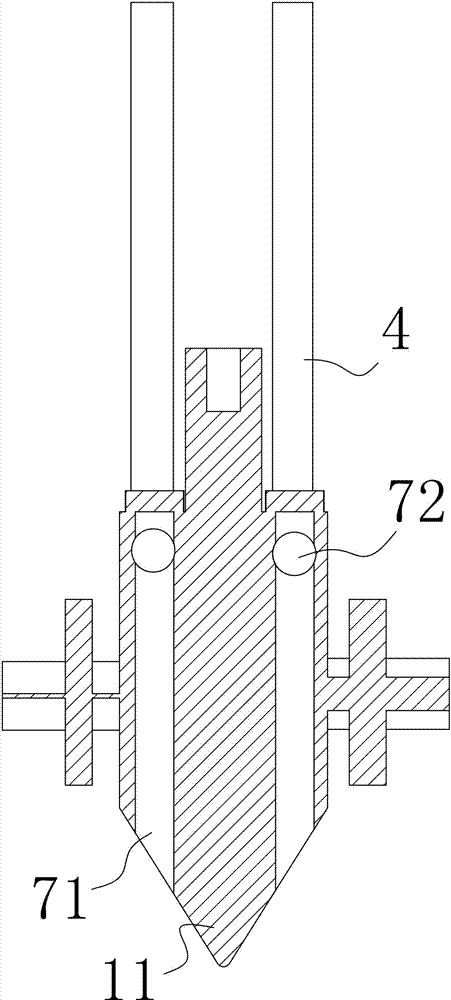

[0019] The pressure maintaining indenter includes an indenter main body; the indenter main body includes a wedge-shaped tip 11 and a rectangular block body portion 12; it also includes a heating frame 21, the heating frame 21 is concave, and the indenter body is located at In the heating rack 21, a heating rod 22 for heating the main body of the indenter is arranged on the heating rack 21, and one end of the heating rod 22 abuts against the main body of the indenter.

[0020] In this embodiment, the top surface of the body part 12 is provided with a mounting block 31, and the top surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com