A kind of fpc pressure holding machine coated with wear-resistant material

一种耐磨材料、保压机的技术,应用在仪器、印刷电路、光学等方向,能够解决牢固性差、元件损伤、影响操作人员身体健康等问题,达到解决凝固问题、解决散热问题的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

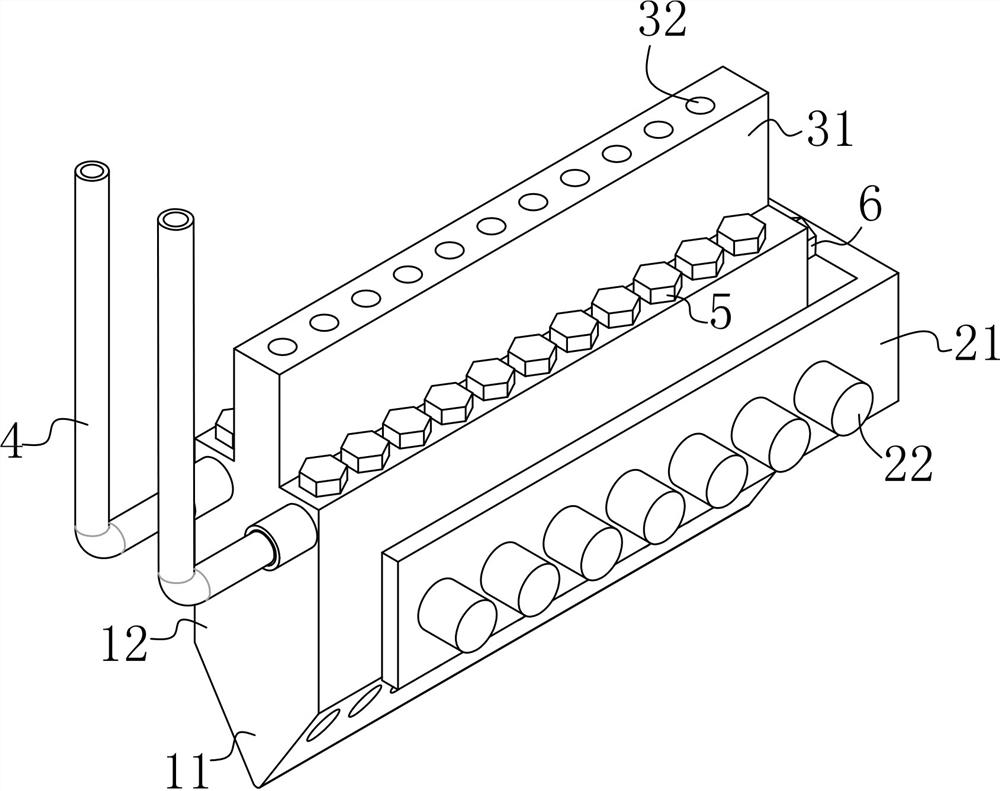

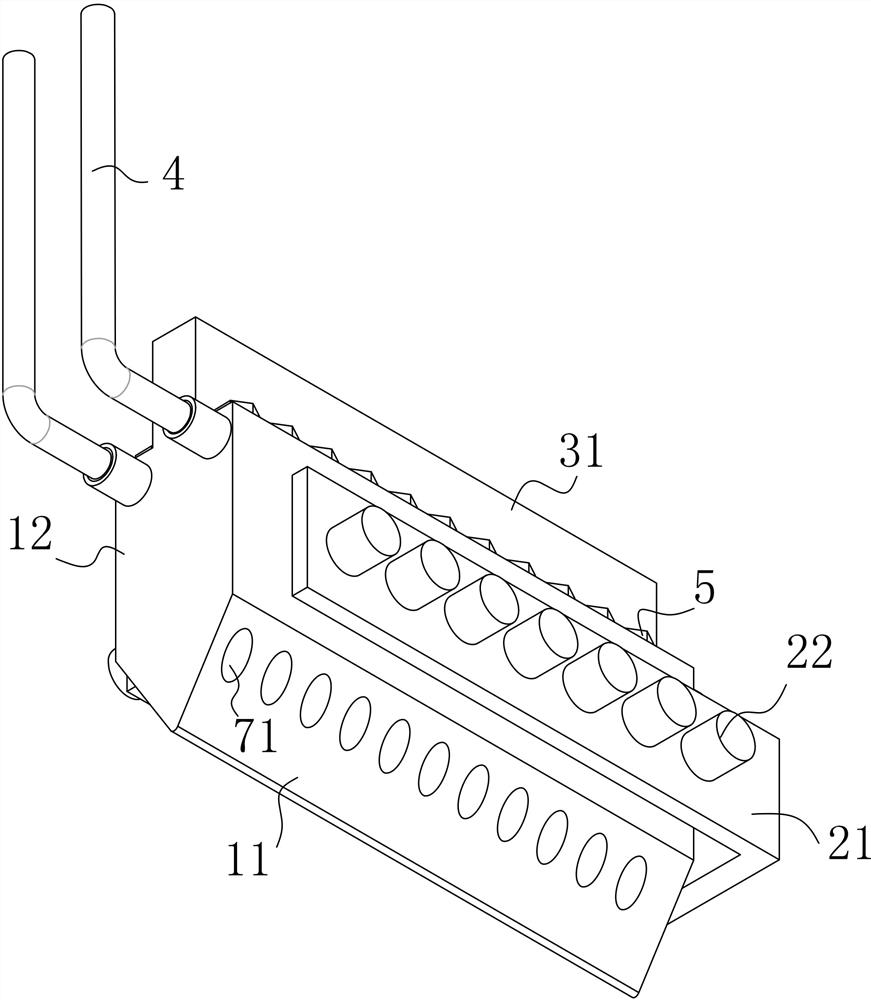

[0018] Such as Figure 1 to Figure 4 As shown, a kind of FPC pressure holding machine coated with wear-resistant material described in this embodiment includes a frame and a shelf plate for placing FPC. The frame is provided with a downward pressure cylinder, and the power output end of the downward pressure cylinder A holding pressure head is attached.

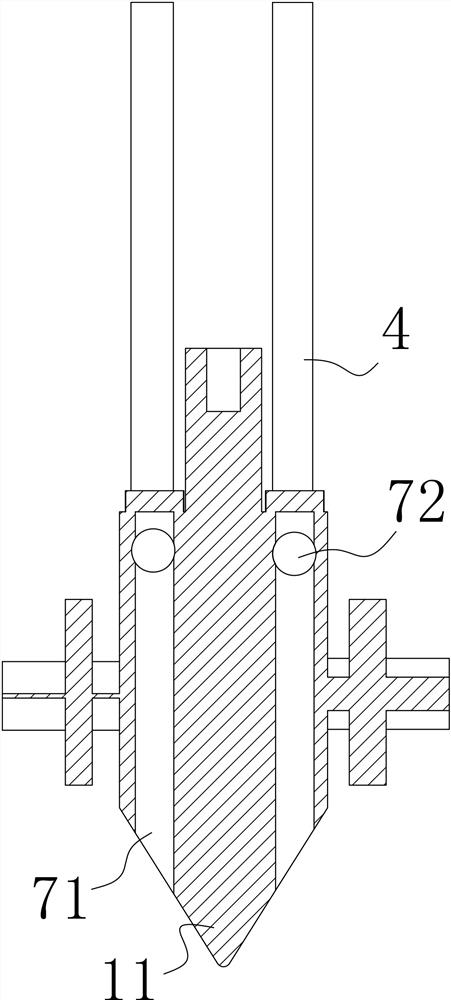

[0019] The pressure maintaining indenter includes an indenter main body; the indenter main body includes a wedge-shaped tip 11 and a rectangular block body portion 12; it also includes a heating frame 21, the heating frame 21 is concave, and the indenter body is located at In the heating rack 21, a heating rod 22 for heating the main body of the indenter is arranged on the heating rack 21, and one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com