Coating concretion preventing coating barrel

A paint bucket and material bucket technology, which is applied to impact-sensitive items, internal accessories, packaged item types, etc., can solve the problems of large water addition ratio, low emulsion content, and the inability of paint buckets to solve precipitation and solidification. The effect of solving precipitation, solving coagulation and precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

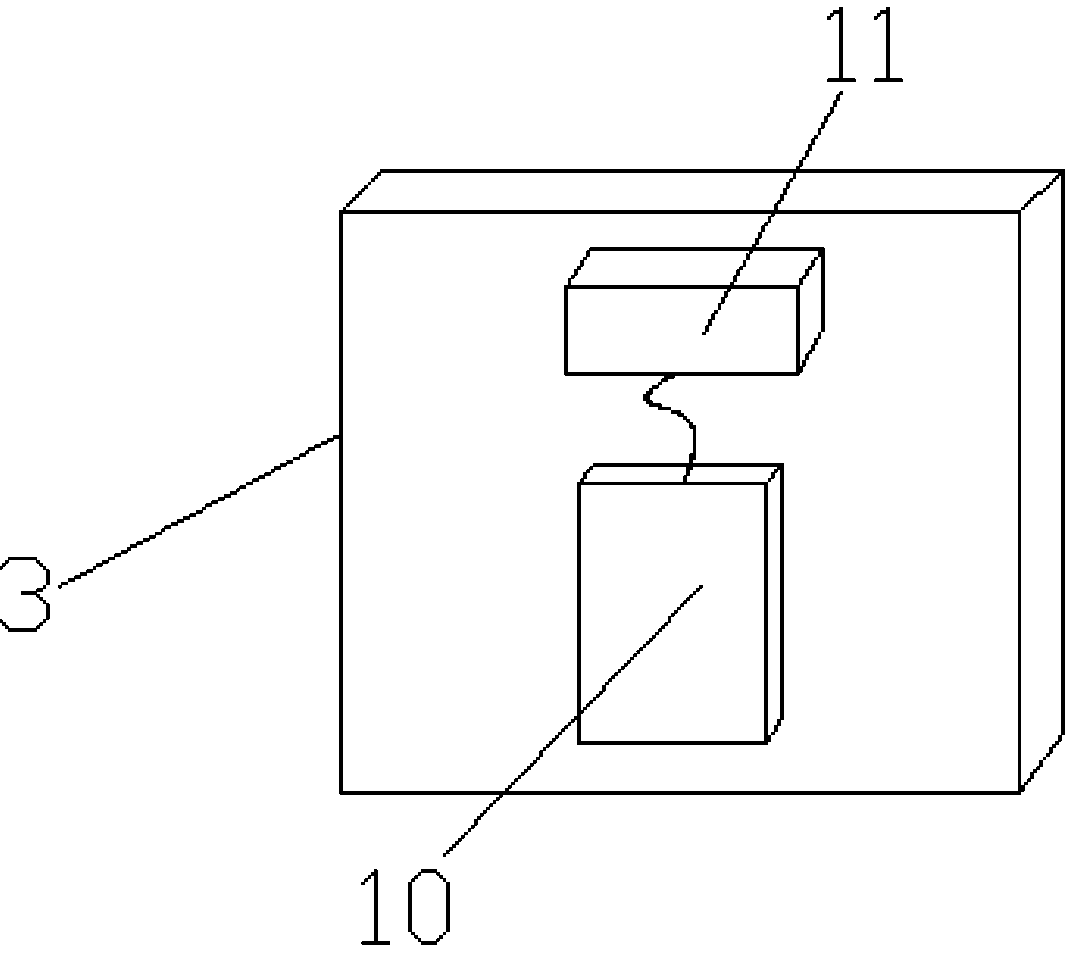

[0021] As a preferred embodiment of the present invention, the motor controller 12 is provided with a control chip inside, and the control chip is provided with a motor speed control module and a running time control module. Through the motor speed control module and the running time control module, the motor speed and running time can be controlled through the control buttons outside the motor control box.

[0022] As a preferred embodiment of the present invention, the outer wall of the power box 2 is provided with a rubber film layer, and the rubber film layer is nested and fixed on the outer wall of the power box 2 by fixing screws. The rubber film layer has a certain anti-slip and insulating effect, which is convenient for handling and prevents electric shock.

[0023] As a preferred embodiment of the present invention, the temperature controller 10 is provided with a temperature control module and a circuit protection module. The temperature control module can control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com