Chemical heat regeneration type diesel engine

A technology of chemical heat recovery and diesel engine, which is applied in mechanical equipment, engine components, combustion engines, etc., can solve the problems of high fuel consumption and low efficiency of diesel engines, and achieve the effects of improving combustion efficiency, improving efficiency, and reducing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

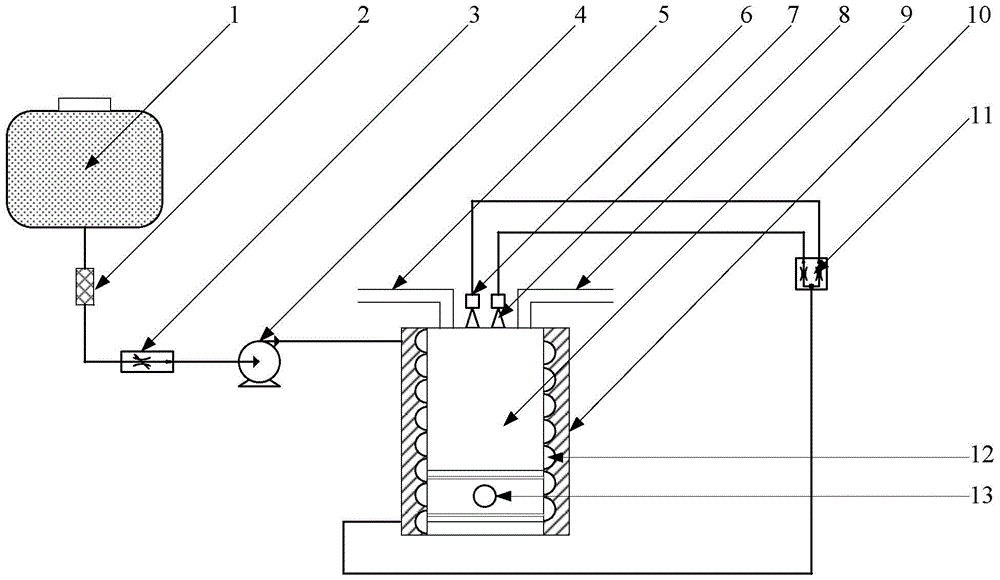

[0018] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the chemical regenerative diesel engine described in this embodiment includes a fuel tank 1, a filter 2, a flow regulating valve 3, a booster pump 4, an intake pipe 5, a liquid fuel nozzle 6, a gaseous fuel nozzle 7, an exhaust Air pipe 8, cylinder 9, switching valve 11, cooling channel 12 and piston 13,

[0019] The top end cover of the cylinder 9 is provided with an intake pipe 5, a liquid fuel nozzle 6, a gaseous fuel nozzle 7 and an exhaust pipe 8; the outer wall of the cylinder 9 is provided with a spiral cooling channel 12; the inner cavity of the cylinder 9 is provided with a piston 13;

[0020] The switching valve 11 is used for switching between the cold fuel oil circuit and the hot fuel oil circuit;

[0021] When the engine is running, the diesel oil flows out from the fuel tank 1 and after being filtered by the filter 2 and regulated by the flow regulating valve 3,...

specific Embodiment approach 2

[0027] Specific Embodiment 2: This embodiment will further describe Embodiment 1, and also includes a ceramic heat insulating layer 10, which is arranged outside the cooling channel 12 to reduce the heat dissipation of high-temperature oil and gas in the cylinder 9 to the environment. Further increase the heat recovery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com