Horizontal vibration screen of steel slag and triple screening method

A vibrating sieve and steel slag technology, applied in chemical instruments and methods, sieves, solid separation, etc., to achieve strong integrity, avoid energy consumption, and facilitate on-site maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

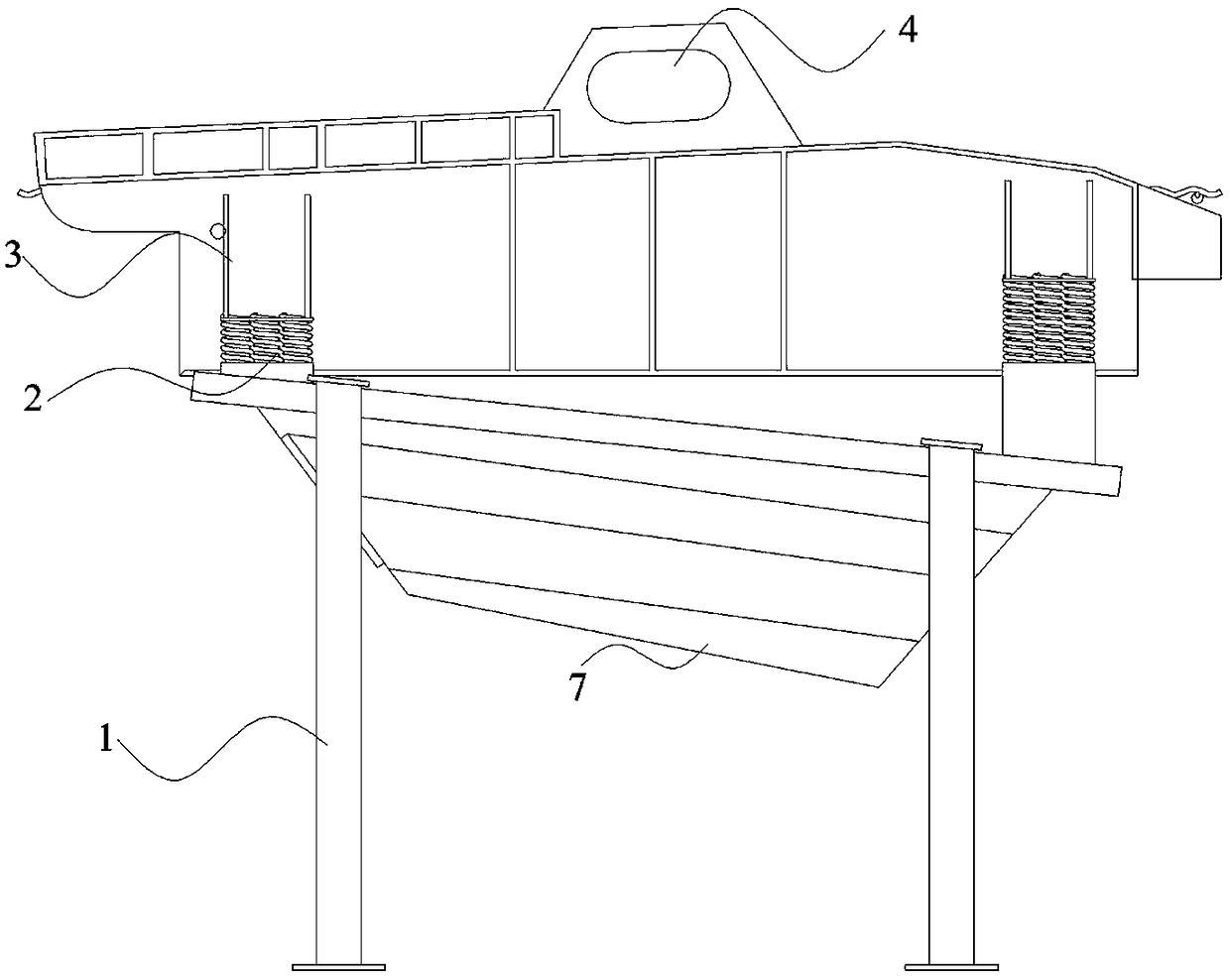

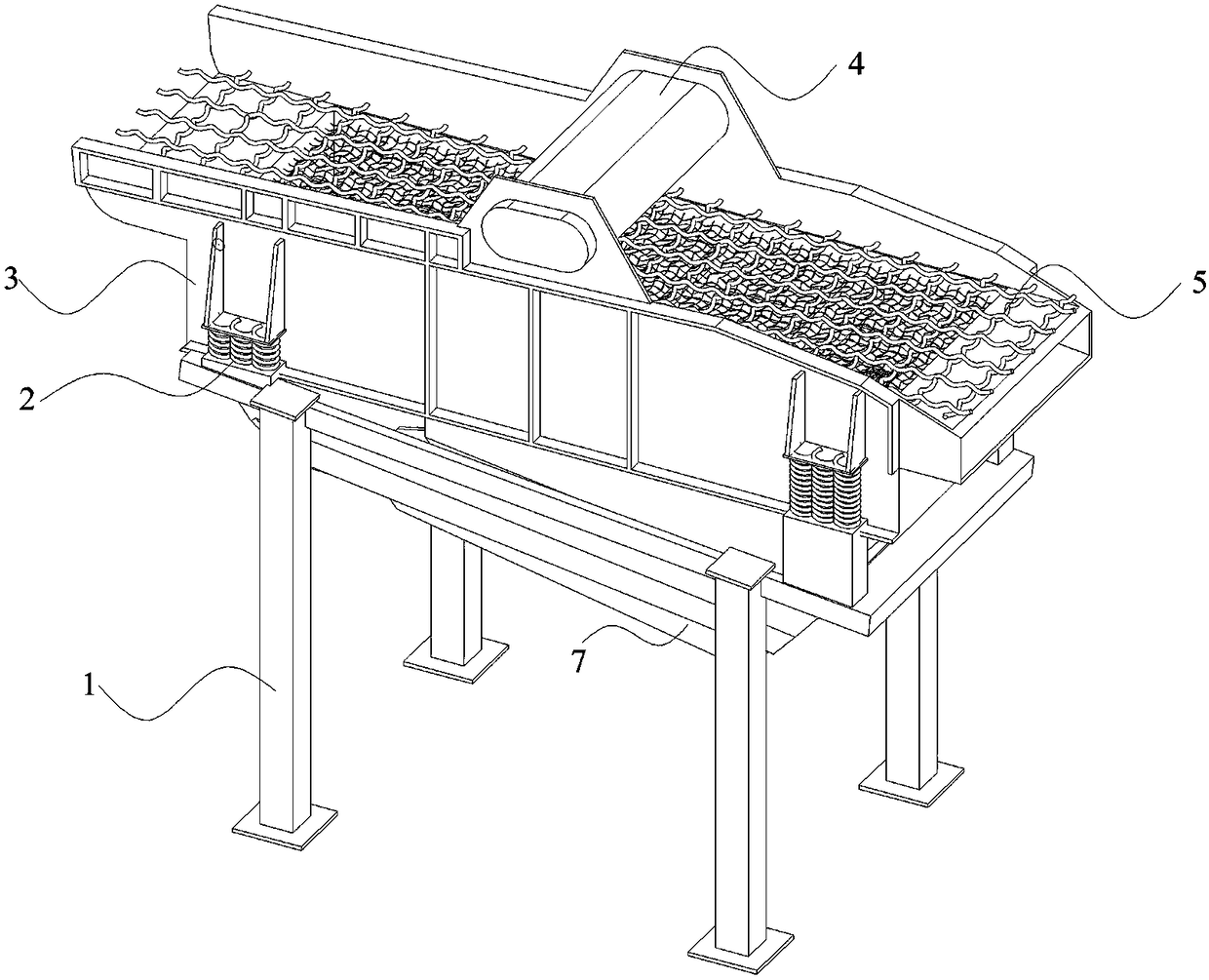

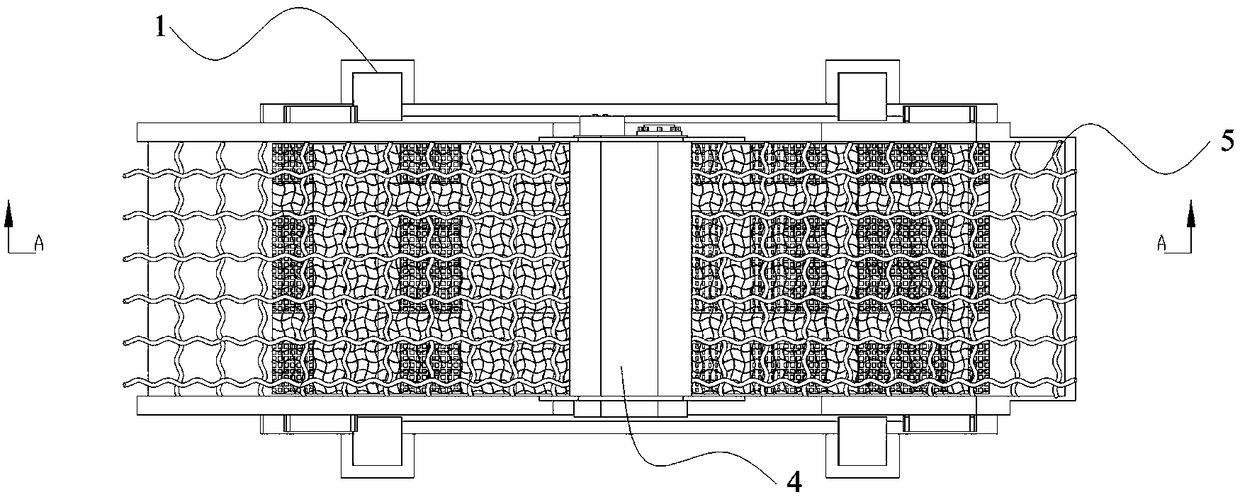

[0024] The steel slag horizontal vibrating screen of this embodiment is such as figure 1 , figure 2 , image 3 with Figure 4 As shown, it includes a frame 1 and a vibrating screen 3. The lower silo is fixedly connected to the frame 1, and a support spring 2 is used to support the vibrating screen 3 on the top of the frame, and the vibration exciter 4 is fixedly installed on the vibrating screen 3. The top screen 5 and the middle screen 6 are installed inside the vibrating screen 3. The surface area of the two-layer screen reaches 8 square meters, and the top of the lower silo 7 receives the middle screen 6. The lower bin 7 is in the shape of a small bucket up and down, with an inclined output port at the bottom, and a conveyor belt arranged obliquely below the output port. The two-layer screens are designed with different apertures, and screen quickly during the vibration process. The supporting spring 2 corresponds to the mounting bosses on the four corners of the vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com