Light emitting diode and preparation method thereof

A technology of light-emitting diodes and light-emitting layers, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of increasing the adhesion between the light-emitting layer and the chip, and the easy precipitation of phosphors, so as to improve the uniformity of the glue and reduce the production cost. , The effect of improving the consistency of light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

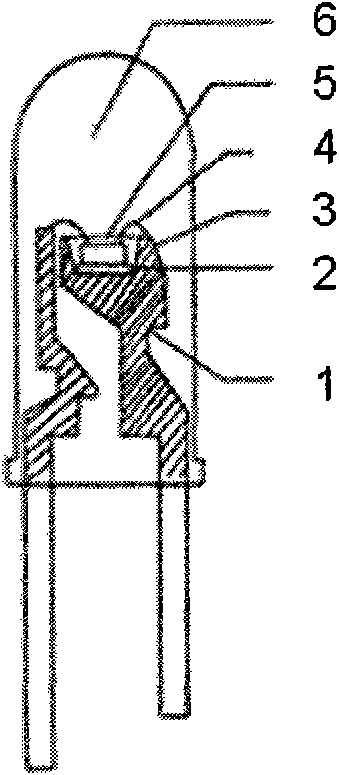

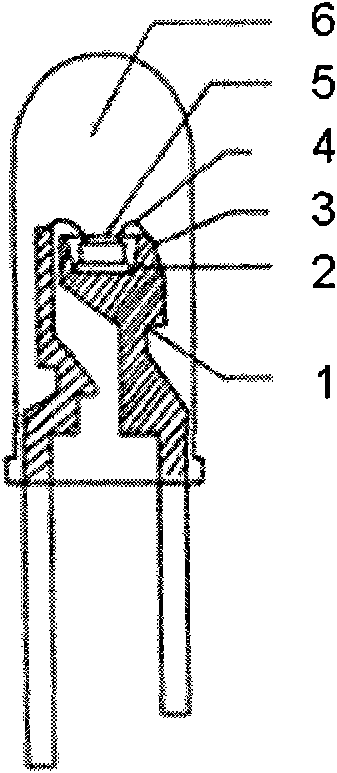

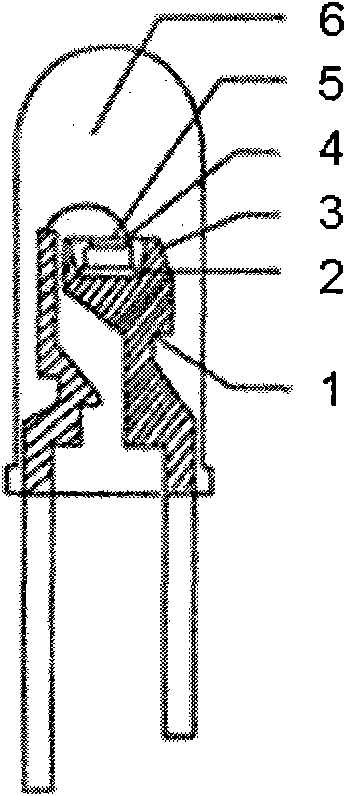

[0090] Such as figure 2 In the device structure shown, the LED chip 3 is a blue LED chip, the luminescent layer 5 is a mixed system of fluorescent powder excited by blue light to produce yellow light and an adhesive that needs to be cured by ultraviolet light, and the bracket 1 is a copper bracket with a silver-plated surface.

[0091] The preparation method is as follows:

[0092] ①Choose a suitable die-bonding glue to glue the blue LED chip on the bracket;

[0093] ② Lead out the electrodes on the LED chip;

[0094] ③ drop-coat the luminescent layer material on the LED chip, the luminescent layer is a mixed system of yellow fluorescent powder and an adhesive that needs to be cured by ultraviolet light, and the adhesive raw material includes the following components in mass percentage:

[0095] Unsaturated polyester resin or acrylic resin 95%

[0096] Styrene and its derivatives 1%

[0097] Photoinitiator 2%

[0098] Photosensitizers and additives 2%

[0099] ④ UV-curi...

Embodiment 2

[0106] Such as figure 2 As shown in the device structure, the LED chip 3 is a blue LED chip, the light-emitting layer 5 is a mixed system of fluorescent powder excited by blue light to generate green light and an adhesive that needs to be cured by ultraviolet light, and the bracket 1 is a copper bracket with silver-plated surface.

[0107] The preparation method is as follows:

[0108] ①Choose a suitable die-bonding glue to glue the blue LED chip on the bracket;

[0109] ② Lead out the electrodes on the LED chip;

[0110] ③ Spraying the luminescent layer material on the LED chip, the luminescent layer is a mixed system of green fluorescent powder and an adhesive that needs to be cured by ultraviolet light, and the adhesive raw material includes the following components in mass percentage:

[0111] Unsaturated polyester resin or acrylic resin 95%

[0112] Styrene and its derivatives 0.5%

[0113] Photoinitiator 4%

[0114] Photosensitizers and additives 0.5%

[0115] ④ U...

Embodiment 3

[0119] Such as figure 2 As shown in the device structure, the LED chip 3 is a blue LED chip, the light-emitting layer 5 is a mixed system of fluorescent powder excited by blue light to generate red light and an adhesive that needs to be cured by ultraviolet light, and the bracket 1 is a copper bracket with a silver-plated surface.

[0120] The preparation method is as follows:

[0121] ①Choose a suitable die-bonding glue to glue the blue LED chip on the bracket;

[0122] ② Lead out the electrodes on the LED chip;

[0123] ③ Dip-coating the luminescent layer material on the LED chip, the luminescent layer is a mixed system of red fluorescent powder and an adhesive that needs to be cured by ultraviolet light, and the raw material of the adhesive includes the following components in mass percentage:

[0124] Unsaturated polyester resin or acrylic resin 95%

[0125] Styrene and its derivatives 0.6%

[0126] Photoinitiator 1.4%

[0127] Photosensitizers and additives 3%

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com