Absorbent for collecting and separating CO2 and use thereof

An absorbent and organic solvent technology, applied in the field of CO2 absorbent, can solve the problems of large circulation volume, small absorption capacity of absorbent, limited absorption capacity, etc., and achieve the effects of increasing solubility, reducing energy consumption, and reducing circulation consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolve 75g of dimethyl carbonate in 10g of diethoxymethane, 10g of octane, and 5g of undecane to obtain CO 2 absorbent. The freezing point of this absorbent is -6.42°C.

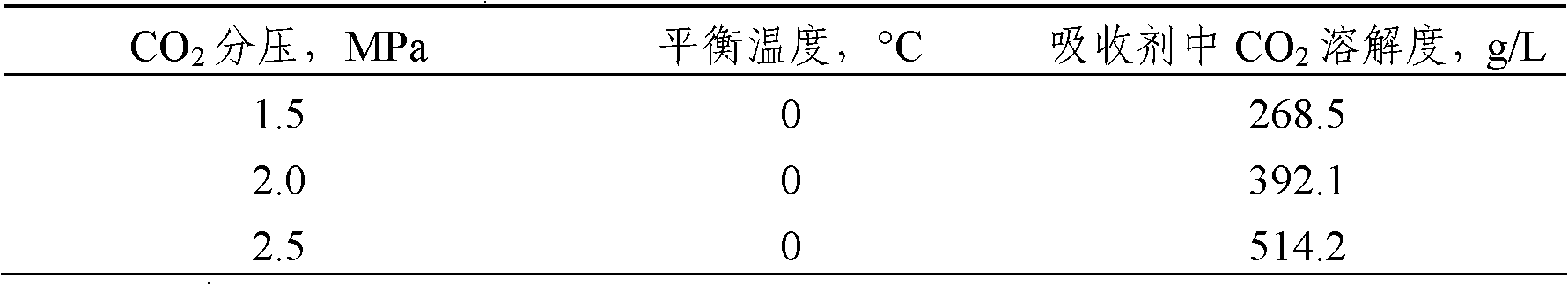

[0023] Get three parts of each 150g above-mentioned absorbent, wherein dimethyl carbonate is 75% (weight), temperature is 0 ℃, gas phase CO 2 Partial pressures of 1.5MPa, 2.0MPa and 2.5MPa containing CO 2 and N 2 The mixed gas is passed into the above three absorbents respectively, and the ventilation is stopped after the gas-liquid two-phase reaches equilibrium.

[0024] Absorbent CO 2 The solubility is shown in Table 1.

[0025] Table 1 Absorption effect of absorbent at 0℃

[0026]

Embodiment 2

[0028] Dissolve 75g of dimethyl carbonate in 10g of diethoxymethane, 10g of octane, and 5g of undecane to obtain CO 2 absorbent. The freezing point of this absorbent is -6.42°C.

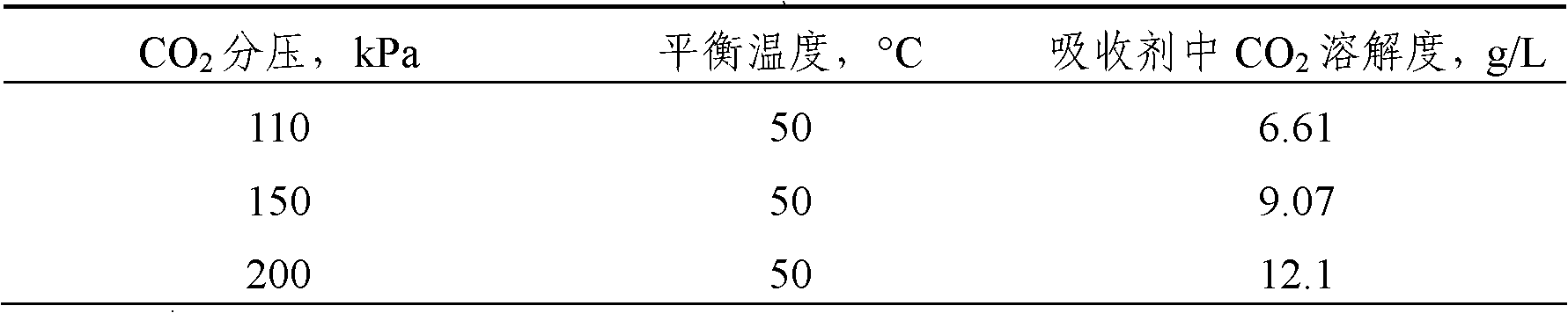

[0029] Get three parts of each 150g above-mentioned absorbent, wherein dimethyl carbonate is 75% (weight), temperature is 50 ℃, gas phase CO 2 Partial pressures of 110kPa, 150kPa and 200kPa containing CO 2 and N 2 The mixed gas is passed into the three absorbents respectively, and after the gas-liquid two-phase reaches equilibrium, the ventilation is stopped.

[0030] Absorbent CO 2 The solubility is shown in Table 2.

[0031] Absorption effect of absorbent at 250°C

[0032]

Embodiment 3

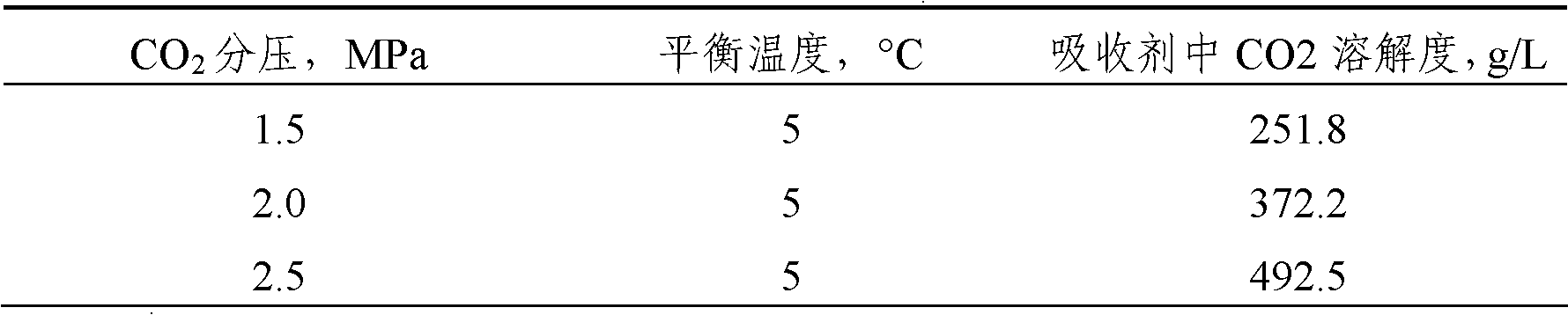

[0034] Dissolve 60g of dimethyl carbonate in 15g of 2-hexanol, 15g of n-decyl alcohol, and 10g of ethylene glycol to obtain CO 2 absorbent. The freezing point of this absorbent was -14.2°C.

[0035] Get three parts of each 150g above-mentioned absorbing agent, wherein dimethyl carbonate is 60% (weight), temperature is 5 ℃, gas phase CO 2 Partial pressures of 1.5MPa, 2.0MPa and 2.5MPa containing CO 2 and N 2 The mixed gas is passed into the three absorbents respectively, and after the gas-liquid two-phase reaches equilibrium, the ventilation is stopped.

[0036] Absorbent CO 2 The solubility is shown in Table 3.

[0037] Table 3 Absorption effect of absorbent at 5°C

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com