Continuous fiber fabric reinforced thermoplastic polyurethane composite material and preparation method thereof

A thermoplastic polyurethane and continuous fiber technology, applied in the field of polymer composite materials and their preparation, can solve the problem of high cost of fluidized bed equipment, and achieve the effects of ensuring complete infiltration, simple production equipment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

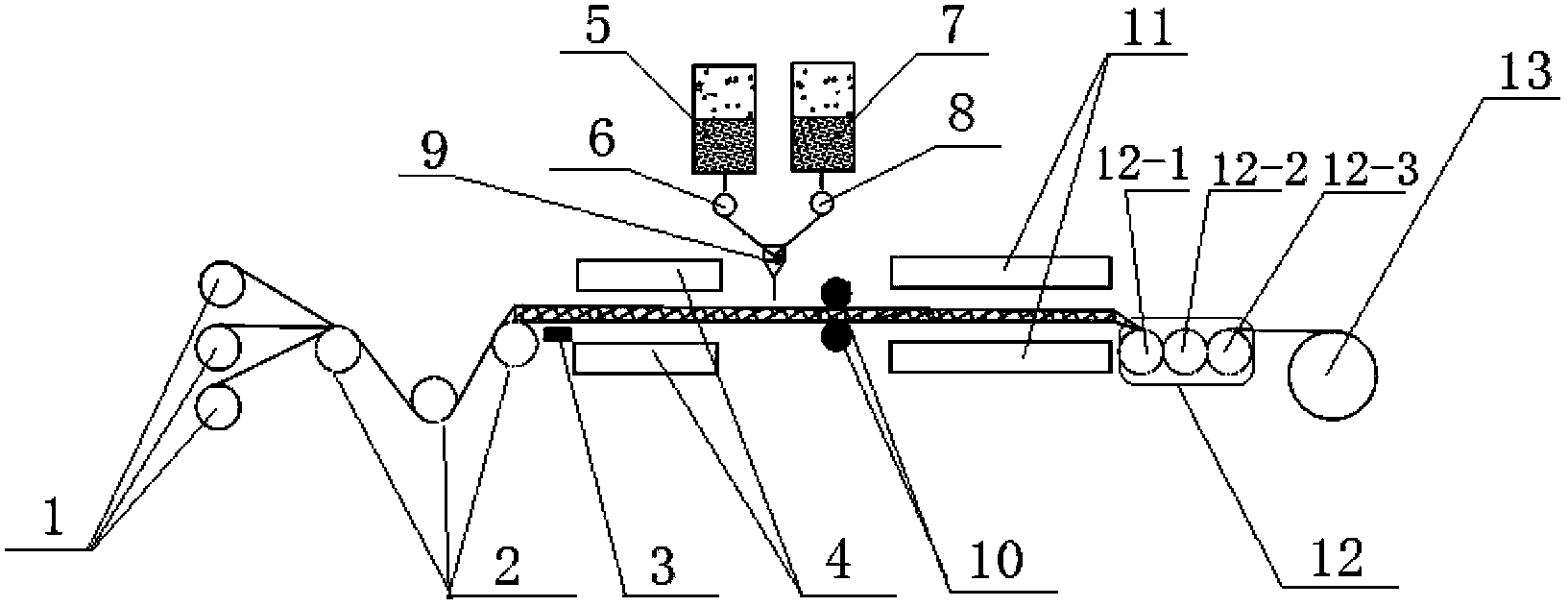

[0036] figure 1 It is a process flow diagram of the present invention.

[0037] (1) Eliminate static electricity and preheat: The unwinding fiber roll or unwinding roll 1 on the creel or unwinding device provides continuous glass fiber rolls (PPG company 45882400tex), and then the continuous glass fiber rolls enter a set of tension rolls 2 Finally, through the static elimination device 3, after the static electricity is eliminated, the continuous glass fiber roll enters the preheater 4, and the infrared heating method is adopted, and the temperature is set at 80 ° C for preheating;

[0038] (2) Impregnation: step (1) the preheated continuous glass fiber roll enters the impregnation unit, and the impregnation unit has the above two filling components, the isocyanate component tank 5 and the polyether component tank 7, which are respectively isocyanate A mixture of component (carbodiimide modified liquefied MDI) and polyether component (polytetrahydrofuran diol 1000, chain exte...

Embodiment 2

[0042] The technological process of this embodiment is as figure 1 shown.

[0043] (1) Eliminate static electricity and preheat: The unwinding fiber roll or unwinding roll 1 on the creel or unwinding device provides continuous carbon fiber rolls (Toray T70024K), and then the continuous carbon fiber rolls enter a set of tension rolls 2, After the static electricity is eliminated through the static elimination device 3, the continuous carbon fiber roll enters the preheater 4, and the electric heating method is adopted, and the temperature is set at 80°C for preheating;

[0044] (2) Impregnation: step (1) the preheated continuous carbon fiber roll enters the impregnation unit, and the impregnation unit has the above two filling components, the isocyanate component tank 5 and the polyether component tank 7, which are respectively the isocyanate group A mixture of (carbodiimide modified liquefied MDI) and polyether components (polyoxypropylene diol 1000, chain extender 1,4-butaned...

Embodiment 3

[0048] The technological process of this embodiment is as figure 1 shown.

[0049] (1) Eliminate static electricity and preheat: The unwinding fiber roller or unwinding roller 1 on the creel or unwinding device provides continuous glass fiber cloth (Haining Jiete Fiberglass Cloth Industry Co., Ltd.), and then the continuous glass fiber cloth After entering a group of tension rollers 2, pass through the static elimination device 3, after eliminating static electricity, the continuous glass fiber cloth enters the preheater 4, adopts the electric heating method, and sets the temperature at 80°C for preheating;

[0050] (2) Impregnation: The preheated continuous glass fiber cloth in step (1) enters the impregnation unit. The impregnation unit has the above two filling components, the isocyanate component tank 5 and the polyether component tank 7, which are respectively isocyanate Component (carbodiimide modified liquefied MDI) and polyether component (polyoxypropylene diol 800, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com