Supplementary culture medium for shiitake mushroom fermentation and liquid submerged continuous culture method for shiitake mushrooms

The technology of feeding medium and culture method is applied in the field of deep layer continuous culture of shiitake mushrooms, which can solve the problems of low production efficiency of shiitake liquid batch fermentation, intolerance to shearing, and adherent growth, so as to improve the culture efficiency and biological volume, solving the effect of high viscosity and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention has no special limitation on the preparation method of the above-mentioned feed culture medium. By adopting conventional operations in the art, as long as the above-mentioned components can be formulated into the required mixed aqueous solution according to the specified ratio, the feed culture described in the present invention can be obtained. base.

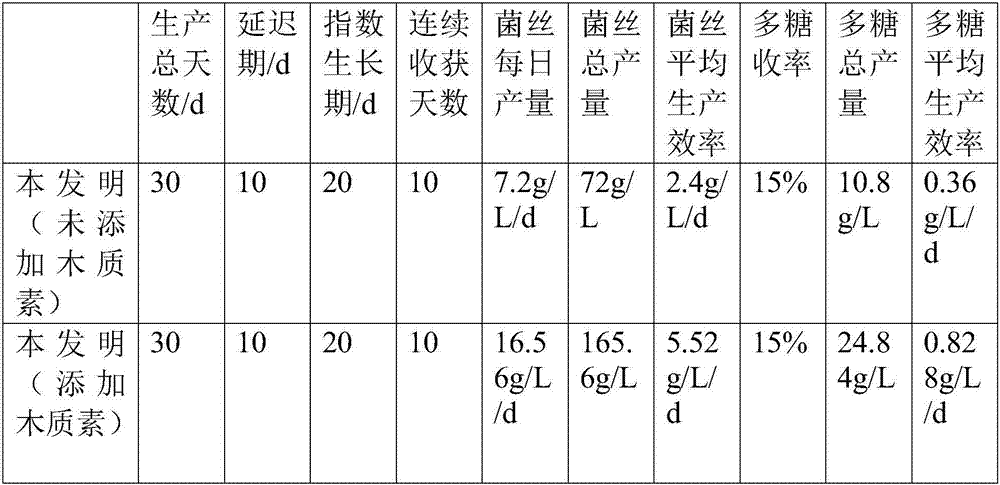

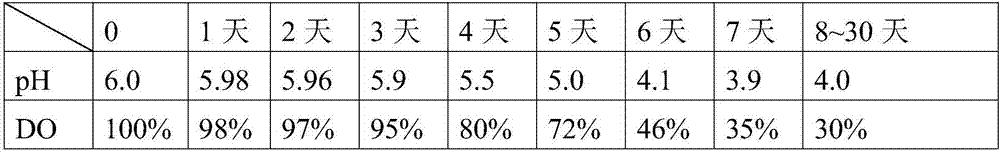

[0039] The present invention also provides a continuous cultivation method of shiitake mushroom liquid, comprising the following steps: inoculating shiitake mushroom seed liquid in a liquid fermentation medium, fermenting and cultivating at a constant temperature at 22-28°C, and controlling the dissolved oxygen of the fermented liquid during the fermentation process. Below 25%, the pH value is 3.5~4.0; After fermentation for 8-12 days, add the feeding medium for mushroom fermentation described in the above technical scheme to the fermented liquid with the feeding rate of dilution rate 0.01-0.04 / h, co...

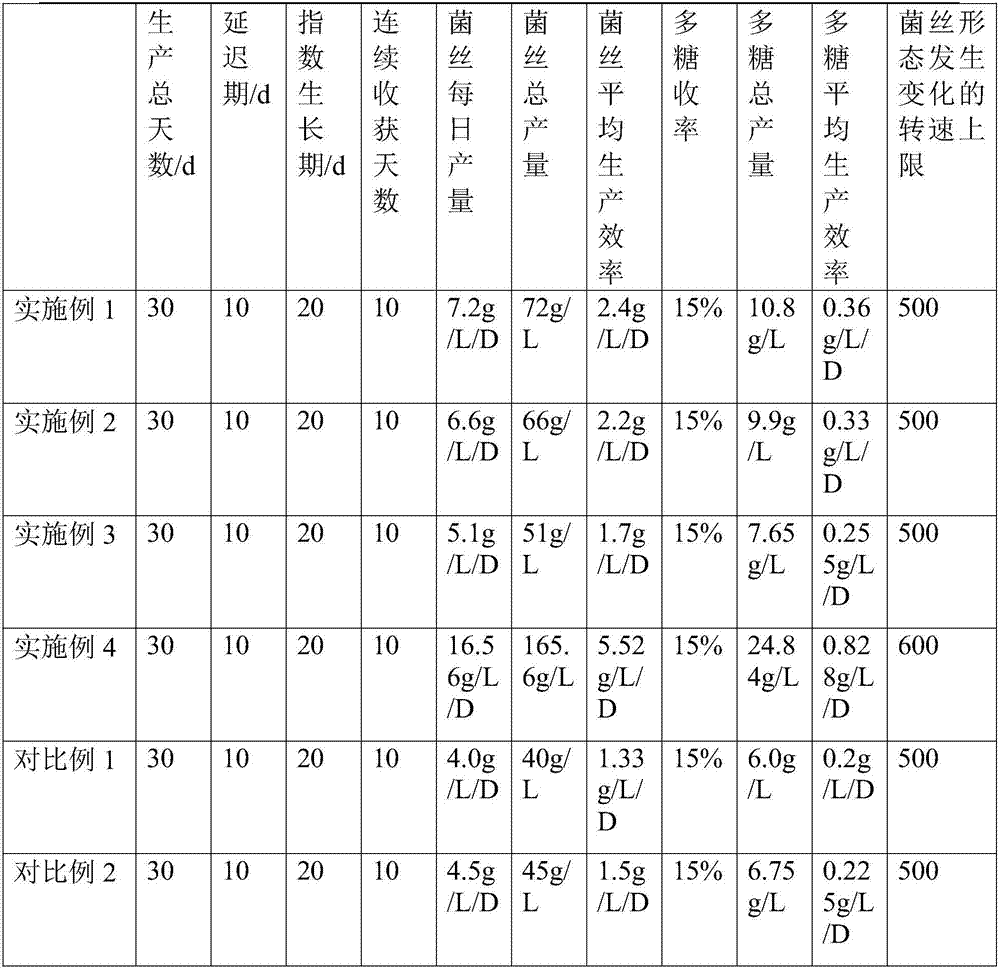

Embodiment 1

[0068] The weight percent of liquid fermentation medium components is as follows: glucose: 5%; polypeptone: 0.25%, yeast extract powder: 0.25%, potassium dihydrogen phosphate: 0.2%, magnesium sulfate: 0.1%, calcium chloride: 0.1%, The rest is tap water.

[0069] Seed bottle preparation: make 1000ml of liquid fermentation medium according to the recipe requirements, and pack into 500ml Erlenmeyer flasks, with a liquid volume of 100ml, and pack into 10 bottles. The mushroom spore liquid was inoculated into the Erlenmeyer flask by the spore liquid inoculation method, the temperature was controlled at 25° C., the rotational speed was 150 rpm, and the shaking culture was ready for use after 10 days.

[0070] Preparation of seed tanks: 30L tanks were used as seed tanks, and 20L medium was prepared as required, kept at 121°C and 110kpa for 50 minutes for sterilization, and cooled to 25°C after sterilization. The above-mentioned 1000ml seed liquid is inserted into the seed tank by me...

Embodiment 2

[0075] The weight percent of liquid fermentation medium components is as follows: glucose: 5%; polypeptone: 0.25%, yeast extract powder: 0.25%, potassium dihydrogen phosphate: 0.2%, magnesium sulfate: 0.1%, calcium chloride: 0.1%, The rest is tap water.

[0076] Seed bottle preparation: make 1000ml of liquid fermentation medium according to the recipe requirements, and pack into 500ml Erlenmeyer flasks, with a liquid volume of 100ml, and pack into 10 bottles. The mushroom spore liquid was inoculated into the Erlenmeyer flask by the spore liquid inoculation method respectively, the temperature was controlled at 25° C., the rotation speed was 150 rpm, and the shake culture was ready for use after 8 days.

[0077]Preparation of seed tanks: 30L tanks were used as seed tanks, and 20L medium was prepared as required, kept at 121°C and 110kpa for 50 minutes for sterilization, and cooled to 25°C after sterilization. The above-mentioned 1000ml seed liquid is inserted into the seed tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com