Low-viscosity and high-strength transparent organic silicon compound as well as preparation method and application thereof

A high-strength, low-viscosity technology, applied in chemical instruments and methods, non-polymer adhesive additives, adhesives, etc., can solve the problems of not being able to obtain transparent silicone rubber products, reducing the transparency of silicone rubber, and increasing the viscosity of silicone rubber , to achieve the effect of solving the contradiction between strength and viscosity, simplifying the production process and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

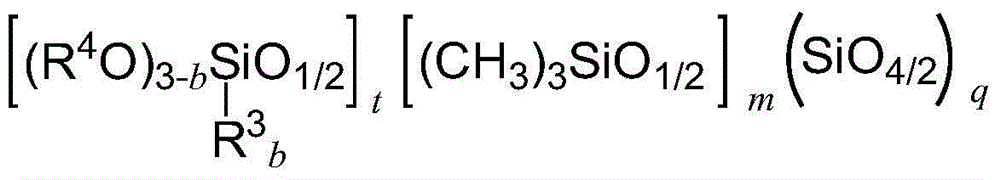

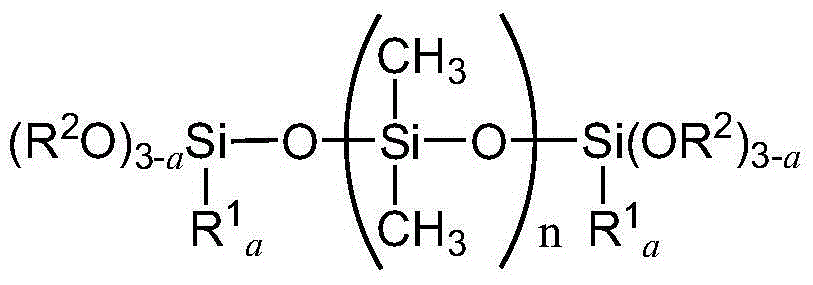

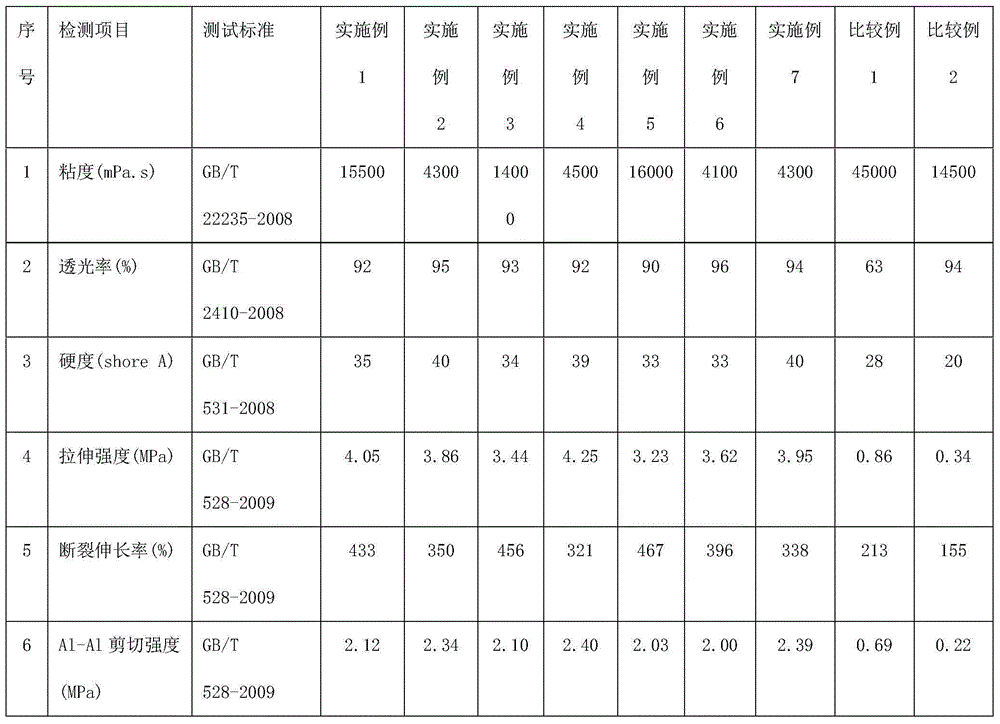

[0039] Example 1. Add 90 parts of vinyl-terminated dimethoxysilyl polydimethylsiloxane with a viscosity of 20,000 mPa.s at 25°C to a high-speed stirring disperser 20 parts of methyl-terminated polydimethylsiloxane with a viscosity of 100 mPa.s at 25°C and 50 parts of alkoxymethyl-terminated MQ silicone resin Where (t+m) / q=0.9, t / m=0.06, at a temperature of 90°C and a vacuum of -0.095MPa, stir at 500 rpm for 50 minutes, then cool to room temperature to make the base material; Add 5 parts of vinyltrimethoxysilane and 0.5 parts of bis(γ-trimethoxysilylpropyl)amine, stir at 150 rpm for 30 minutes under vacuum -0.095MPa; then add 3 parts of tetratitanate For tert-butyl ester, under vacuum -0.095MPa, stir at 150 rpm for 30 minutes, make it evenly mixed and discharge, and fill it in an air-insulated high-density polyethylene tube to obtain a single-component product. Product performance tests and related standards are shown in Table 1.

Embodiment 2

[0040] Example 2. Add 90 parts of trimethoxysilyl-terminated polydimethylsiloxane with a viscosity of 5000mPa.s at 25°C to a high-speed stirring disperser 20 parts of methyl-terminated polydimethylsiloxane with a viscosity of 100 mPa.s at 25°C and 50 parts of alkoxymethyl-terminated MQ silicone resin [(CH 3 O) 3 SiO 1 / 2 ] t [(CH 3 ) 3 SiO 1 / 2 ] m (SiO 4 / 2 ) q , where (t+m) / q=0.9, t / m=0.06, at a temperature of 90°C and a vacuum of -0.095MPa, stirred at 500 rpm for 50 minutes, then cooled to room temperature to make the base material; Add 5 parts of methyltrimethoxysilane and 0.5 parts of 1,3,5-tris(trimethoxysilylpropyl)isocyanurate to the feed, and stir at 150 rpm for 30 minutes under vacuum-0.095MPa; then Add 3 parts of 1,3-cyclopropanedioxydi-tert-butyl titanate, stir at 150 rpm for 30 minutes under a vacuum of -0.095 MPa, make it evenly mixed, and then discharge the material, and fill it in a high-pressure container with no air One-component products are obtained...

Embodiment 3

[0041] Example 3, the low-viscosity, high-strength one-component transparent dealcoholized room temperature vulcanizing silicone composition and its production method, the composition of which is different from that of Example 1 in that the alkoxymethyl-terminated MQ silicon resin The ratios of (t+m) / q and t / m are different, wherein (t+m) / q=1.20 and t / m=0.10 in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com