Adsorption treatment of organic waste gas and desorption and regeneration process of adsorbent

A technology for organic waste gas and adsorption treatment, which is applied in gas treatment, membrane technology, and separation of dispersed particles, etc. It can solve problems such as environmental pollution and safety accidents, and achieve the effect of improving efficiency and using safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

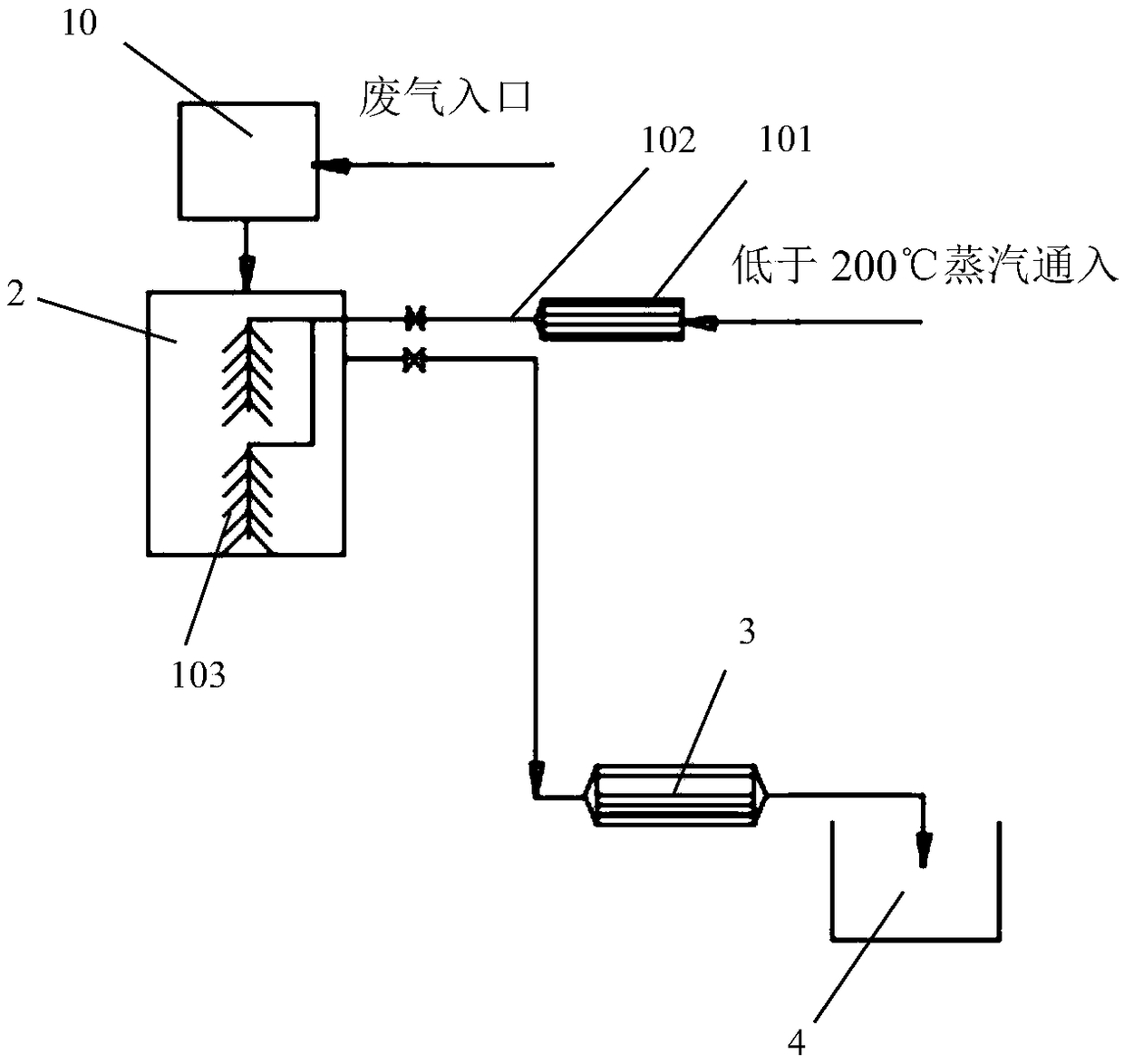

[0021] Such as figure 1 As shown, the present invention provides a device for adsorption treatment of organic waste gas and desorption regeneration of its adsorbent, including a steam injection system, a regeneration tank 2, and a tail gas treatment system. The steam injection system includes a superheated steam generator 101, Primary steam pipe 102, secondary steam pipe 103 and nozzles. Wherein, the accommodating space provided in the regeneration tank 2 and several secondary steam pipelines 103 are arranged in the accommodating space, and one end of the secondary steam pipeline 103 is connected to the superheated steam pipeline 102 through the main steam pipeline 102 The steam generator 101 is provided with the nozzle at the other end. The regeneration tank 2 is provided with an exhaust gas outlet and a purified gas outlet, and the purified gas outlet is located at the bottom of the regeneration tank 2. The exhaust gas outlet is connected to the exhaust gas treatment system...

no. 2 example

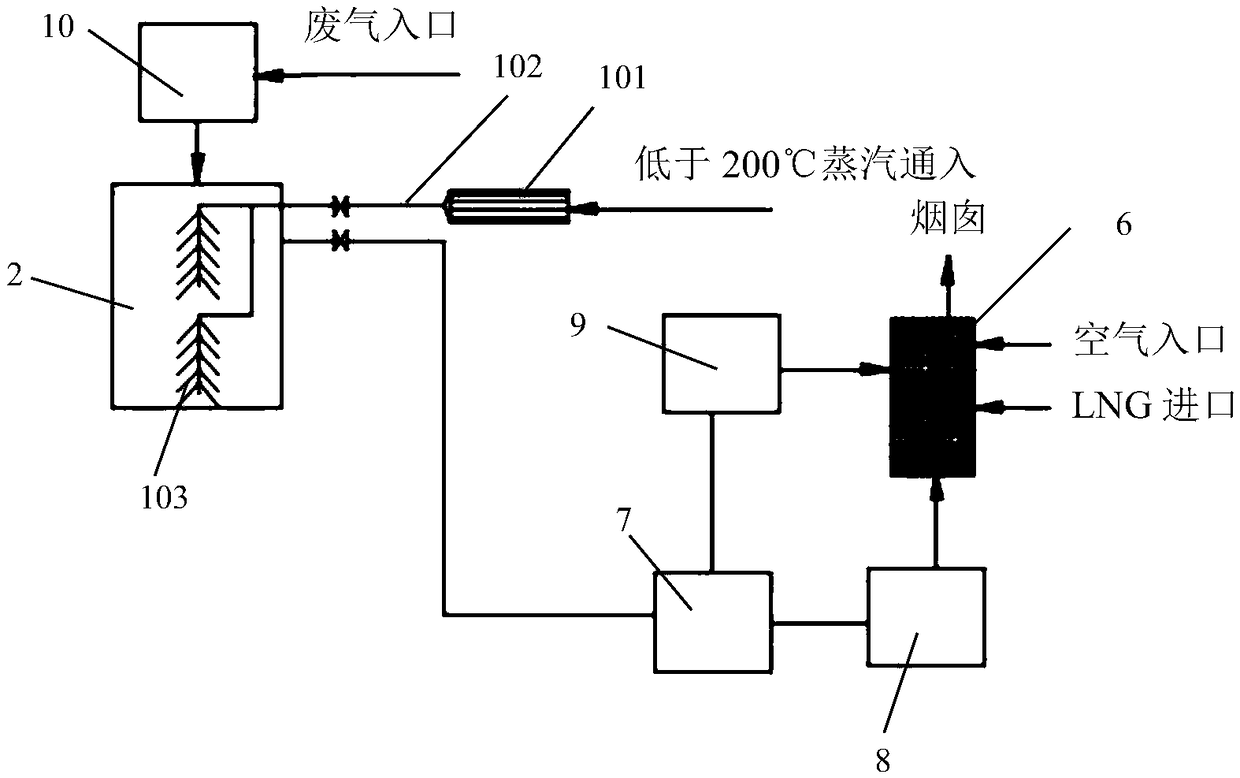

[0031] Such as figure 2 As shown, the equipment for the adsorption treatment of organic waste gas and the desorption regeneration of the adsorbent provided by the present invention includes a steam injection system, a regeneration tank 2, and a tail gas treatment system. The steam injection system includes a superheated steam generator 101, a main Steam pipe 102, secondary steam pipe 103 and nozzles. Wherein, the accommodating space provided in the regeneration tank 2 and several secondary steam pipelines 103 are arranged in the accommodating space, and one end of the secondary steam pipeline 103 is connected to the superheated steam pipeline 102 through the main steam pipeline 102 The steam generator 101 is provided with the nozzle at the other end. The regeneration tank 2 is provided with an exhaust gas outlet and a purified gas outlet, and the purified gas outlet is located at the bottom of the regeneration tank 2. The exhaust gas outlet is connected to the exhaust gas tr...

no. 3 example

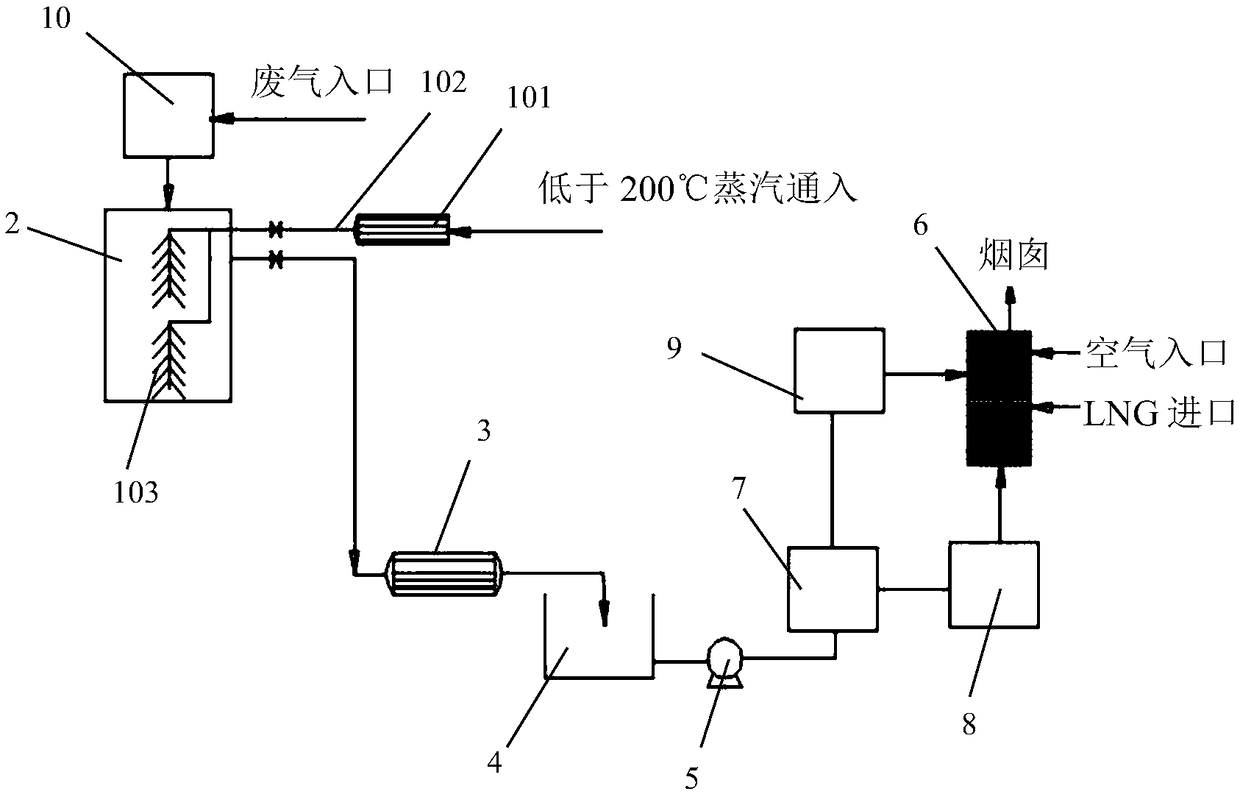

[0041] like image 3 As shown, the equipment for the adsorption treatment of organic waste gas and the desorption regeneration of the adsorbent provided by the present invention includes a steam injection system, a regeneration tank 2, and a tail gas treatment system. The steam injection system includes a superheated steam generator 101, a main Steam pipe 102, secondary steam pipe 103 and nozzles. Wherein, the accommodating space provided in the regeneration tank 2 and several secondary steam pipelines 103 are arranged in the accommodating space, and one end of the secondary steam pipeline 103 is connected to the superheated steam pipeline 102 through the main steam pipeline 102 The steam generator 101 is provided with the nozzle at the other end. The regeneration tank 2 is provided with an exhaust gas outlet and a purified gas outlet, and the purified gas outlet is located at the bottom of the regeneration tank 2. The exhaust gas outlet is connected to the exhaust gas treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com