Heat and water integration process for an oil sand operation with direct steam injection of warm thickener overlfow

a technology of oil sand and integration process, which is applied in the field of oil sand processing, can solve the problems of low heat quality, fouling of heat exchanger transfer area, and fouling of heat transfer surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

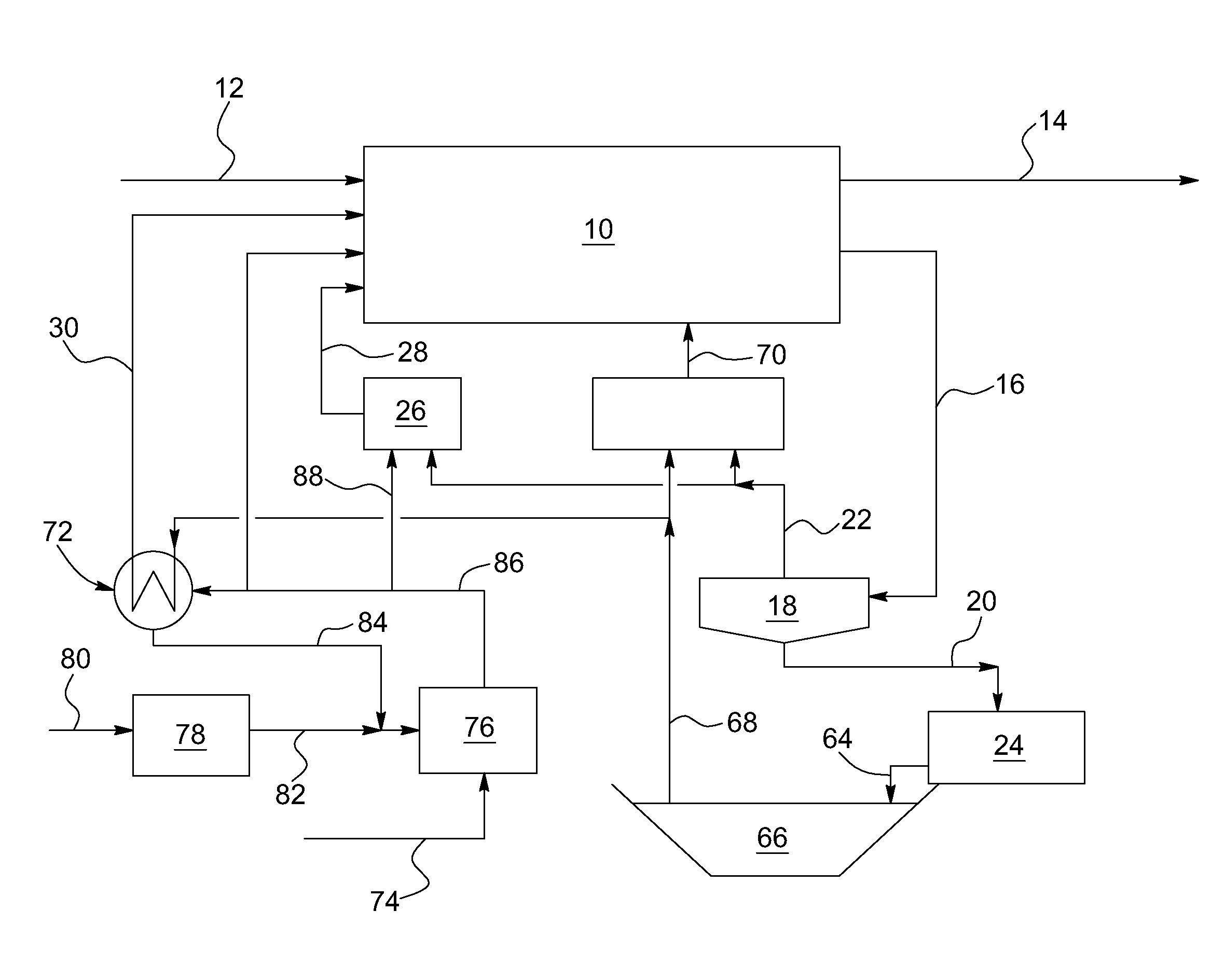

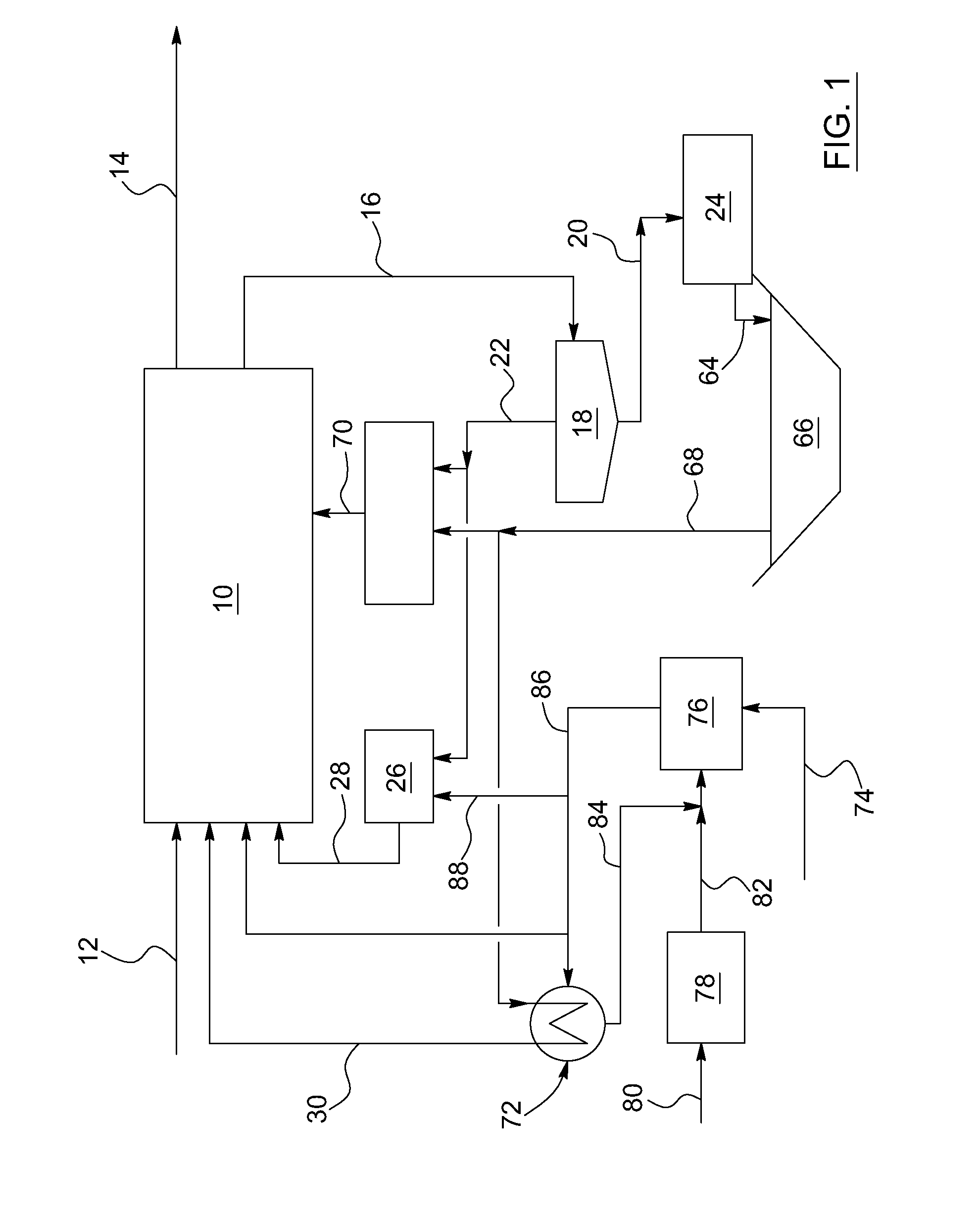

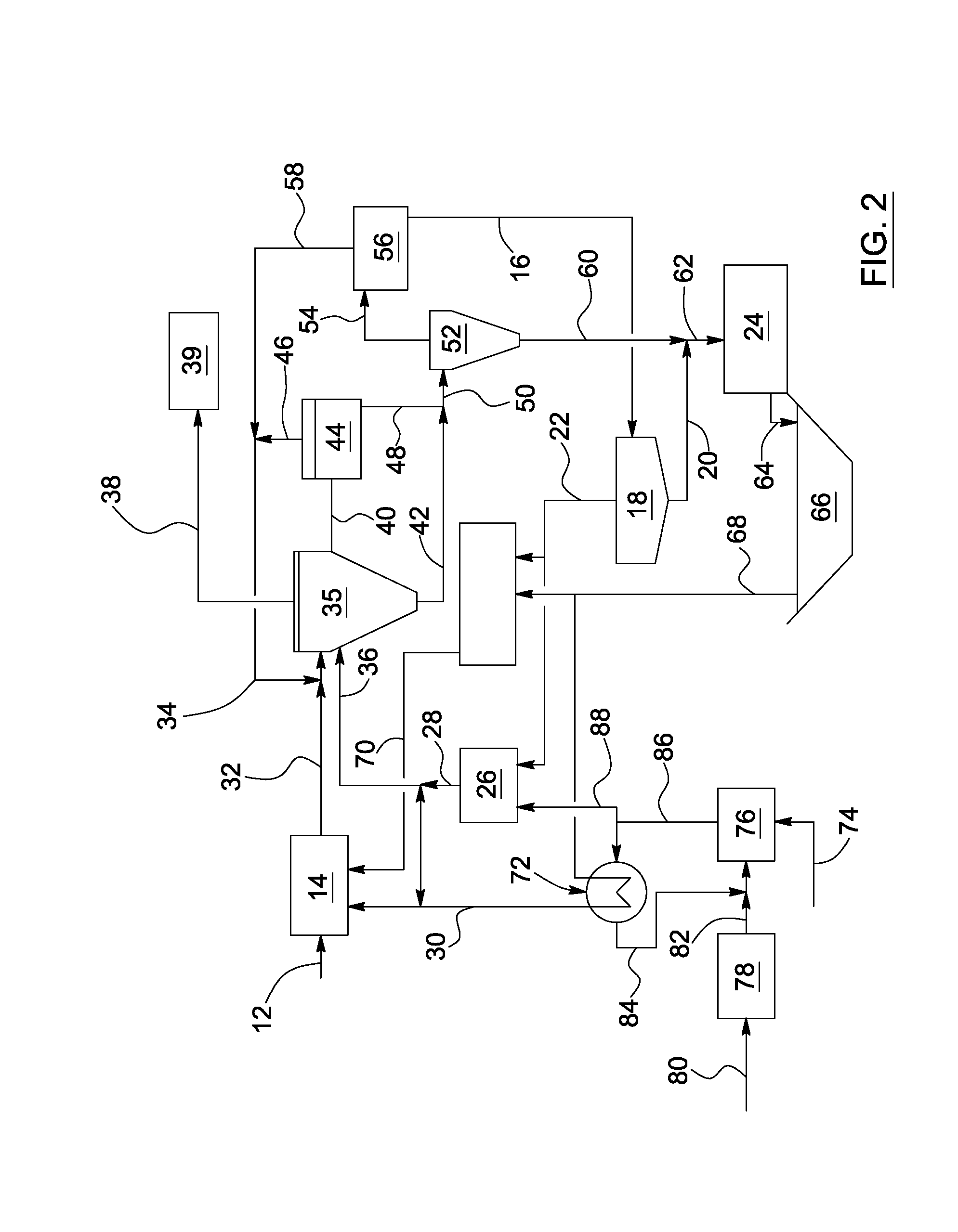

[0042]FIG. 1 illustrates an embodiment of the process of the present invention. In this embodiment, a bitumen production operation 10 receives oil sand 12 and produces a bitumen product 14. The bitumen production operation 10 also receives other process streams and produces output streams. One output stream is a warm tailings stream 16, which contains mineral solids such as sand, silt and clay, residual bitumen and components thereof and water in varying proportions depending on the particular source and processing conditions that generated the tailings.

[0043]In one aspect, the warm tailings stream 16 is produced by a tailings solvent recovery unit (TSRU) for treating the solvent diluted tailings from a bitumen froth separation unit (FSU). The TSRU recovers the solvent from the solvent diluted tailings and generates TSRU tailings. In another optional aspect, the warm tailings stream 16 is derived from middlings and / or bottoms of a primary separation vessel (PSV). More regarding the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com