Downhole equipment, tools and assembly procedures for the drilling, tie-in and completion of vertical cased oil wells connected to liner-equipped multiple drainholes

a technology of vertical cased oil wells and assembly procedures, applied in the direction of drilling pipes, drilling/well accessories, drilling directional drilling, etc., can solve the problems of no safety controls and minimal operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

case 1 (

TWIN WHIPSTOCK)

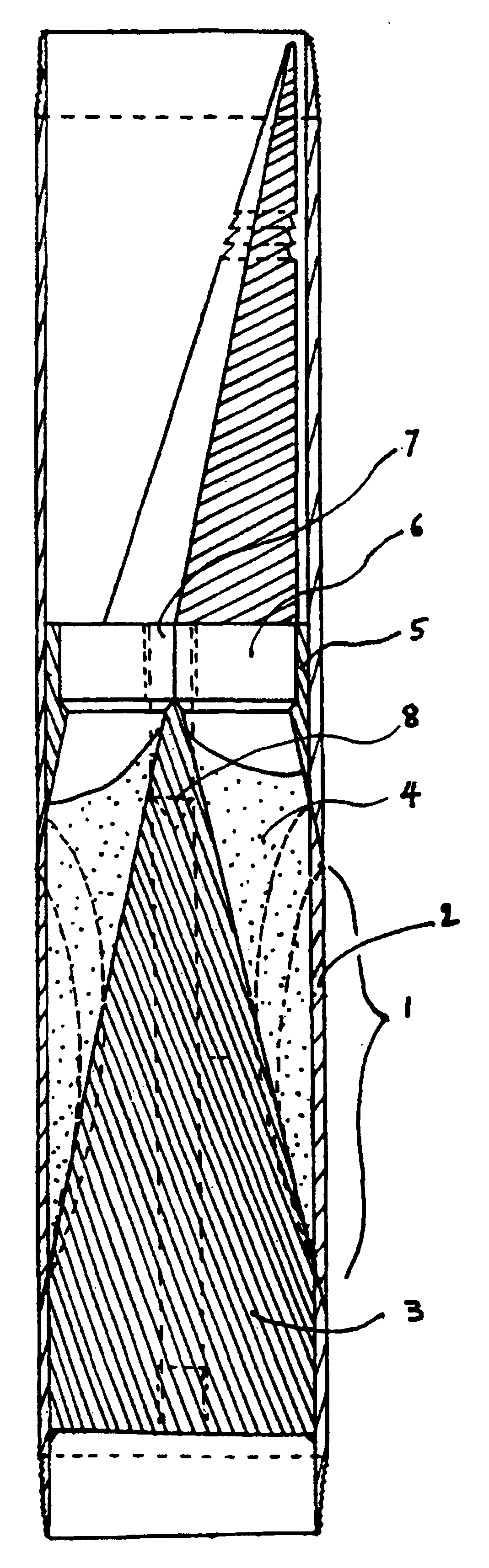

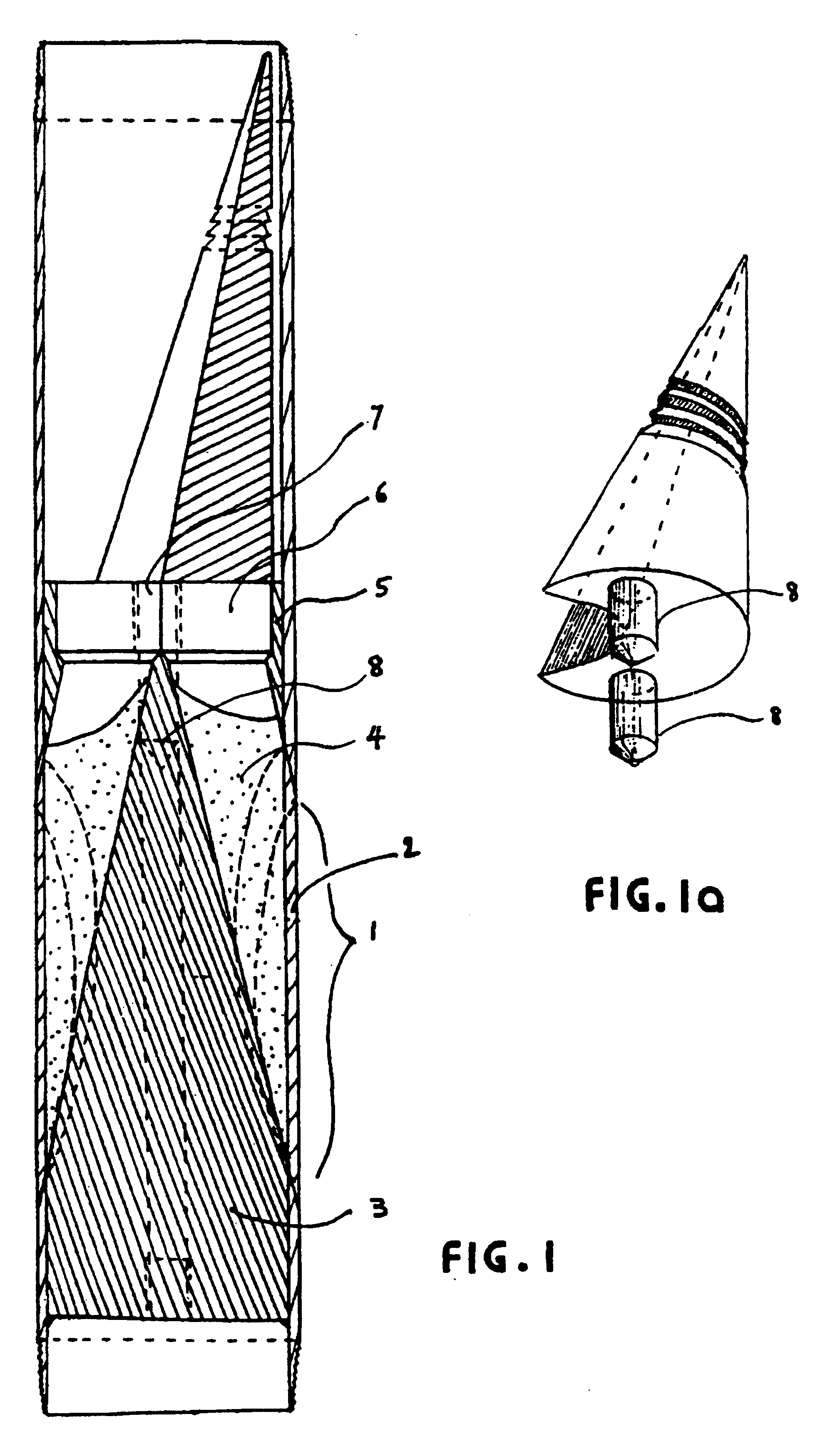

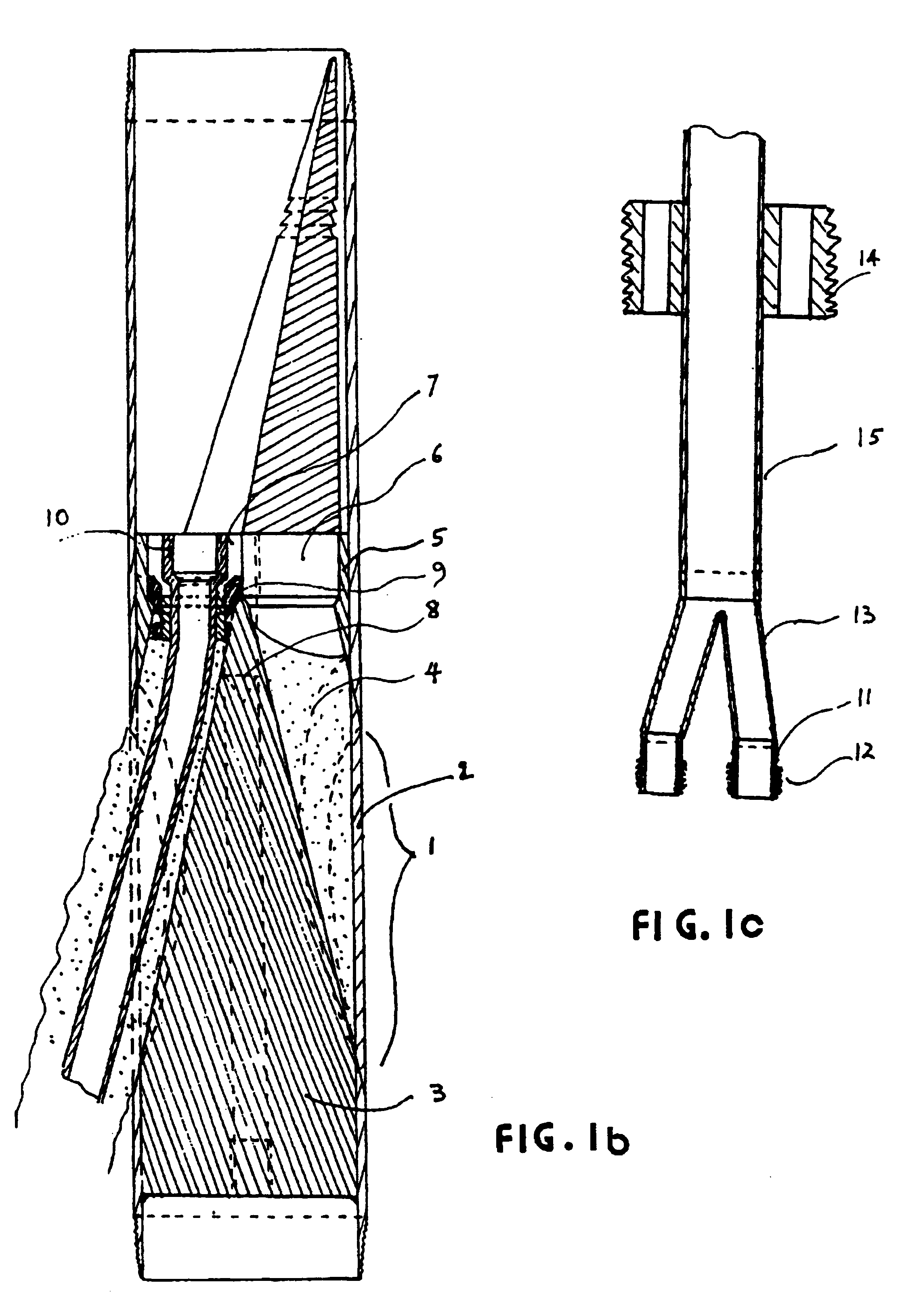

In Case 1 a vertical well is drilled to a depth slightly greater than that of the common kick-off depth of the drainholes. The casing string is made-up by including a special joint immediately above the conventional casing shoe and float collar. This casing joint shown on FIG. 1 includes two elliptical windows (1) machined at the desired kick-off angle, typically about 2 degrees oriented downward from the vertical.

These windows are plugged up with a drillable material (an Aluminum plate (2), for instance) machined to conform with the cylindrical surfaces of the casing. A twin whipstock (3), of hardened metal, is securely fastened to the casing joint, for instance by welding. It provides a curved guiding path from a guide plate above to each of the two plugged windows. For added strength, a portion of that curved guide may be partly filled with cement (4) or other drillable material. The guide plate (5), on top of the whipstock, presents four vertical cylindrical holes...

case 2 (

TWIN DEVIATED HOLES)

In Case 2, from a vertical cased well drilled and cemented by conventional techniques, the casing shoe is drilled out and two short (ca. 50 ft long) smaller diameter twin deviated holes are drilled through the bottom of the vertical well. This uses, for instance, a bit (16) driven by a downhole motor (17) connected to a bent sub (18), in the type of downhole assembly commonly used for drilling horizontal wells (see FIG. 2).

With deviation angles of only a few degrees from the vertical, the separation between the two holes is only of a few feet at the bottom and of a few inches at the top. Consequently, it may be advantageous in some formations, to start the drilling operation by first under-reaming a single large-diameter short hole below the casing shoe, from which the twin small-diameter drainholes are then started, with opposite orientations. Several other available techniques are also familiar to those skilled in the art of drilling oil wells and may be used t...

case 3 (deviated cased well)

.Iadd.Case 3 includes a special casing joint equipped with a drillable packer and retrievable whipstock for drilling and completion of a side-tracked hole. .Iaddend.In Case 3, a vertical well is drilled, with its lower 50 ft deviated at the angle required to kick-off a horizontal drainhole and oriented in the direction selected for the drainholes. A special casing string is made-up, run-in and cemented by known techniques into the vertical and deviated portions of the hole. It consits of a shoe, a float collar and a special casing joint .[.(FIG. 3).]. .Iadd., see FIGS. 3a-3c, .Iaddend.located at a depth slightly above that of the start of the hole deviation. This casing joint presents an elliptical window machined into the casing with a downward orientation of a few degrees from the vertical. .[.The.]. .Iadd.As previously shown in FIG. 1, the .Iaddend.window (1) is again plugged off with a drillable plate (2) made, for instance, of a soft metal and shaped to generally conform with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com