Tri-cogeneration system and tri-cogeneration method for generating power, producing hydrogen and producing fresh water by aid of high-temperature gas-cooled reactor of nuclear power plant

A technology for high-temperature gas-cooled reactors and nuclear power plants, which is applied in nuclear power generation, nuclear power plants, and hydrogen production. The effect of equipment reliability and flexible operation mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

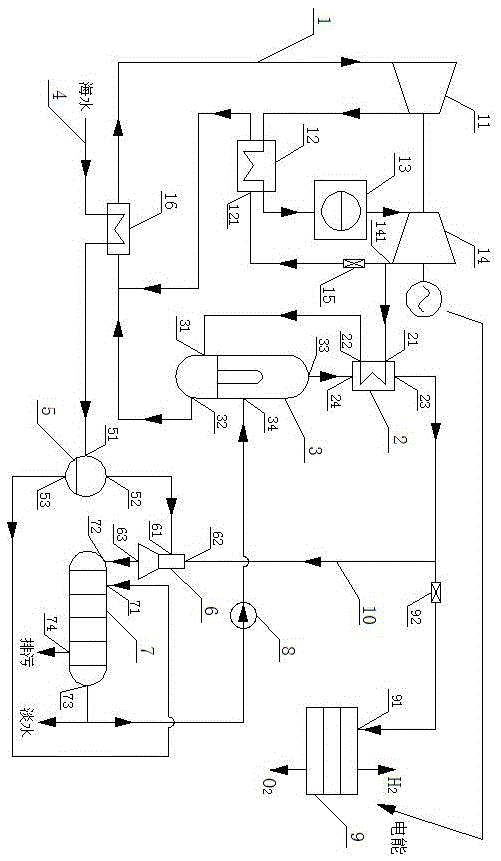

[0022] one , device

[0023] Such as figure 1As shown, the present invention is a nuclear power plant high temperature gas-cooled reactor power generation hydrogen production fresh water three-generation system, which includes a nuclear power plant closed helium circulation system 1, superheater 2, steam generator 3, raw seawater pipeline 4, flash evaporator 5. Steam ejector 6, seawater desalination device 7, feed water pump 8, solid oxide electrolytic cell 9, auxiliary steam pipeline 10. The nuclear power plant closed helium circulation system 1 includes a compressor 11, a regenerator 12, a high temperature gas-cooled reactor 13, a gas turbine generator set 14, a regulating valve 15, a cooler 16 and related pipelines and forms a single loop cycle ; The exhaust outlet 141 of the gas turbine generator set 14 is divided into two paths: one path is connected with the helium inlet 121 on the high temperature side of the regenerator 12 and a regulating valve 15 is set on the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com