Method for preventing coking of visbreaking and heating furnace used for inferior heavy oil

A low-quality heavy oil, heating furnace technology, used in the petroleum industry, non-catalytic thermal cracking, cracking and other directions, can solve the problems of furnace tube wall penetration, decreased heat transfer efficiency, increased medium flow resistance, etc., to achieve uniform flow distribution and easy venting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

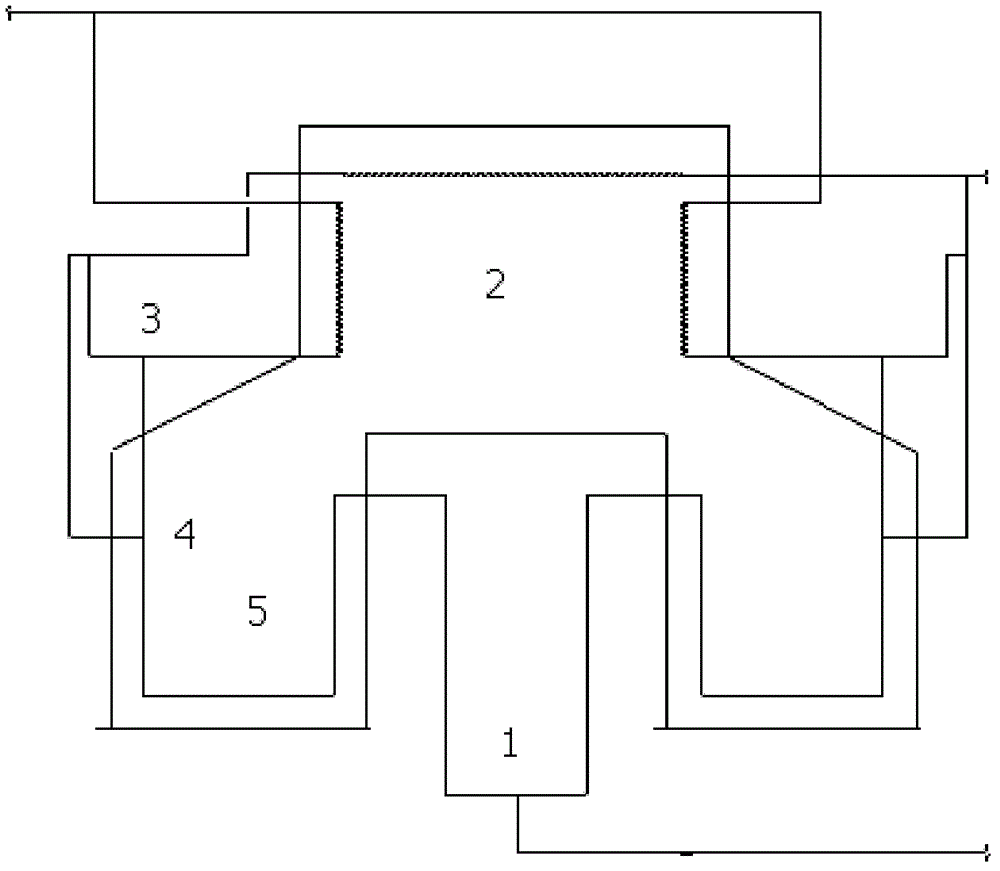

[0015] Such as figure 1 Shown: The visbreaking heating furnace adopts a horizontal tube furnace. Control furnace outlet 1 temperature at 425-435 ℃. Two-point steam injection is adopted, and 1.0MPa steam accounting for 0.5-4% of raw material weight is injected. The first steam injection point 3 is set at the oil transfer line furnace tube from the convection chamber 2 to the radiation chamber 5, and 70% steam is injected to provide the flow velocity of the residual oil condensation reaction stage and slow down the coking rate of the radiation furnace tube at this stage; A second steam injection point 4 is set at the furnace tube in the middle of the radiation chamber 5, and 30% steam is injected to reduce the partial pressure of cracked products. The flow velocity in the furnace tube reaches 1.2-2.0 m / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com