Large-scale three-dimensional simulation method for exploiting super-heavy oil reservoir through FUSE technology

A simulation method, a technology for super heavy oil, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve problems such as shortage, and achieve the effect of reducing steam cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

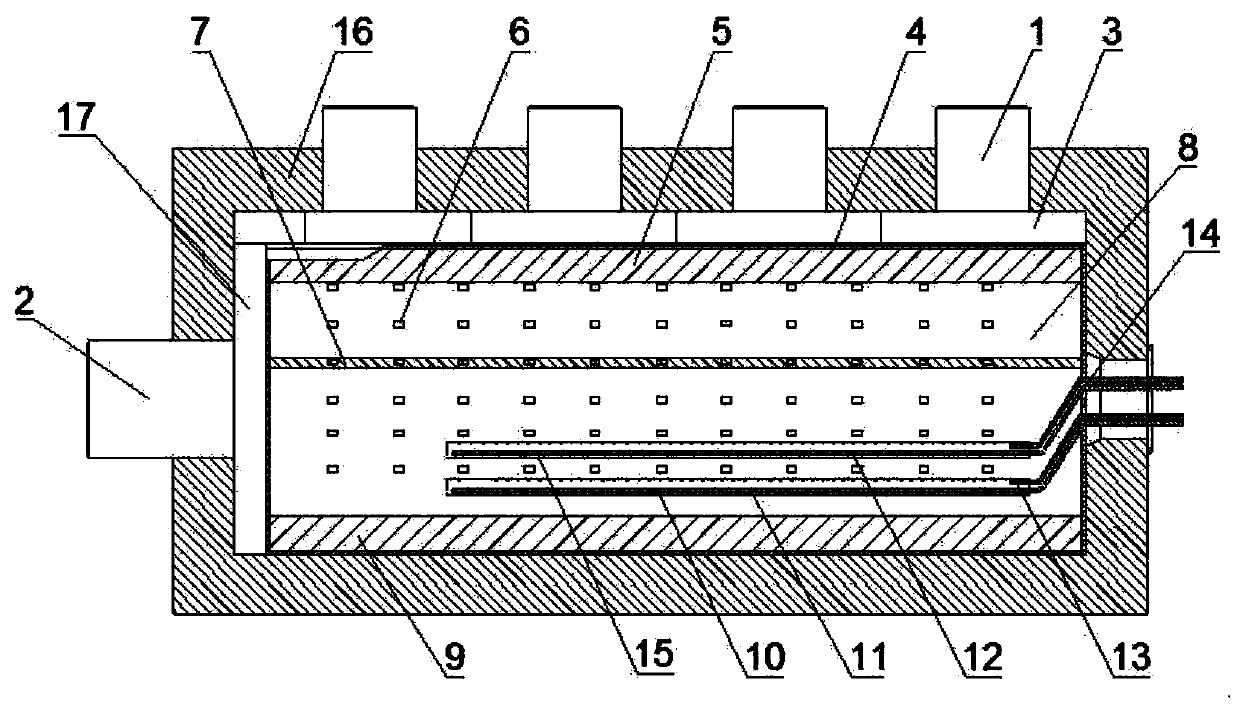

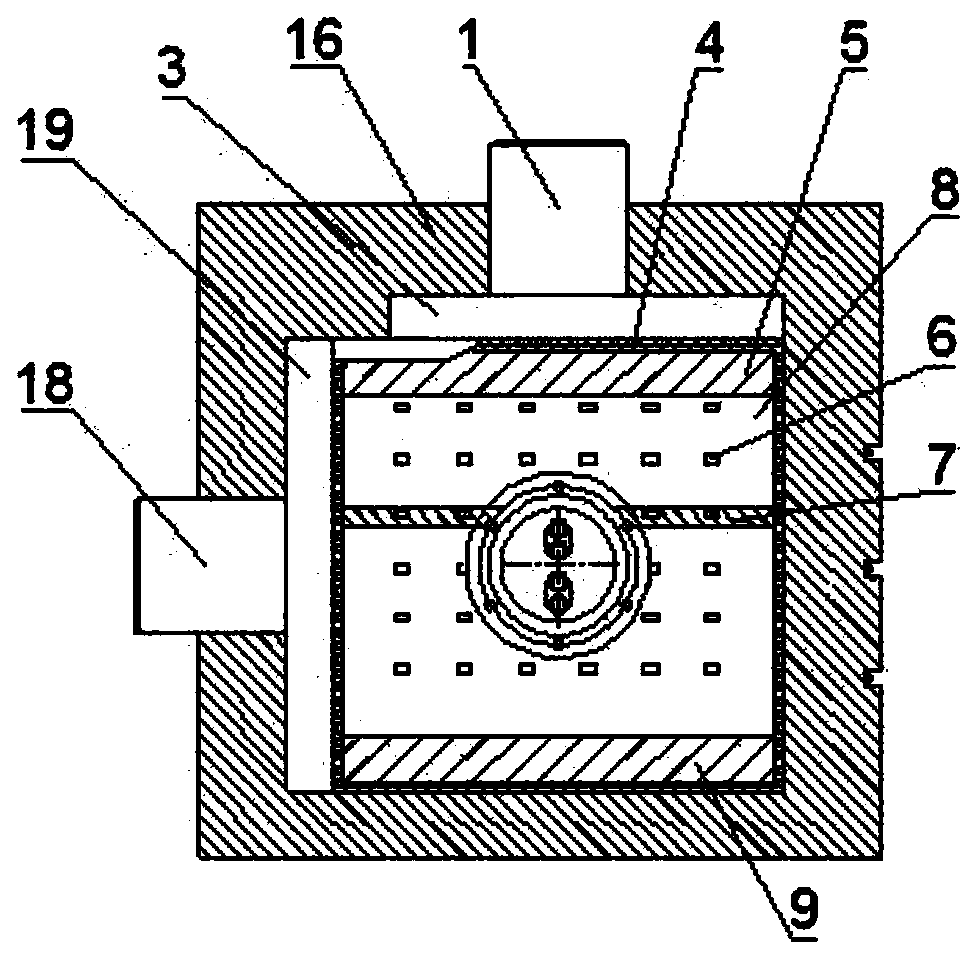

[0036] Below in conjunction with accompanying drawing, the present invention will be further described, embodiment is exemplary, only for revealing and explaining the present invention, in order to fully understand the present invention, but does not therefore limit the present invention to described implementation within the scope of the example.

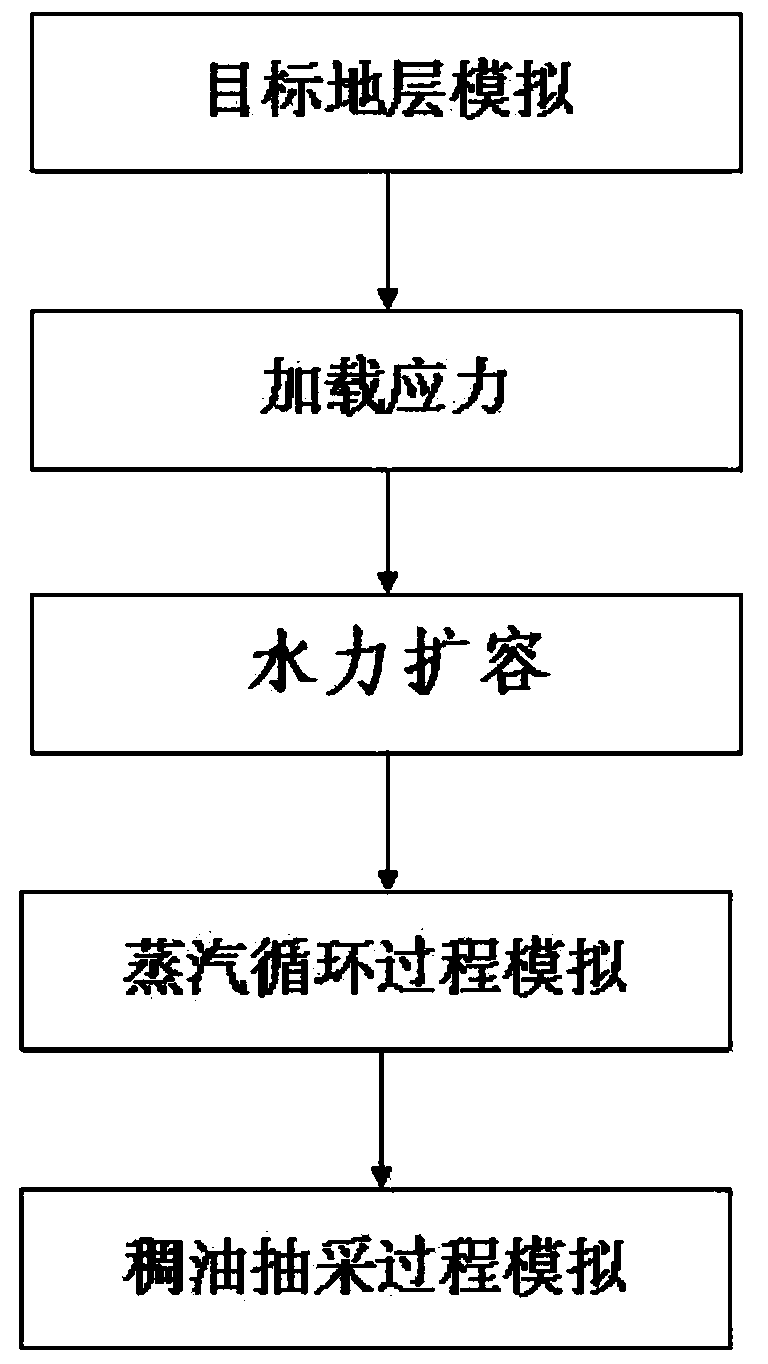

[0037] see figure 1 , a large-scale 3D simulation method for super-heavy oil reservoirs exploited by FUSE technology, carried out under true triaxial loading conditions, and includes the following steps:

[0038] The first step, target stratum simulation: including sample preparation and cable connection; the sample preparation includes sequentially pressing from bottom to top in the true triaxial loading test piece box according to the properties of the core drilled on site The bottom layer, the oil sand reservoir with interlayer and the simulated formation of the caprock, and in the process of suppressing the oil sand reservoir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com