Plane conveying type smoke sprayer oil pump

A conveying type, fog machine technology, applied in variable capacity pump components, liquid variable capacity machines, pumps, etc., can solve the problems of electromagnetic pump parameter errors, unfavorable fine control of oil pumping volume, wear of metal parts, etc. Achieve the effect of simple structure, conducive to fine control and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

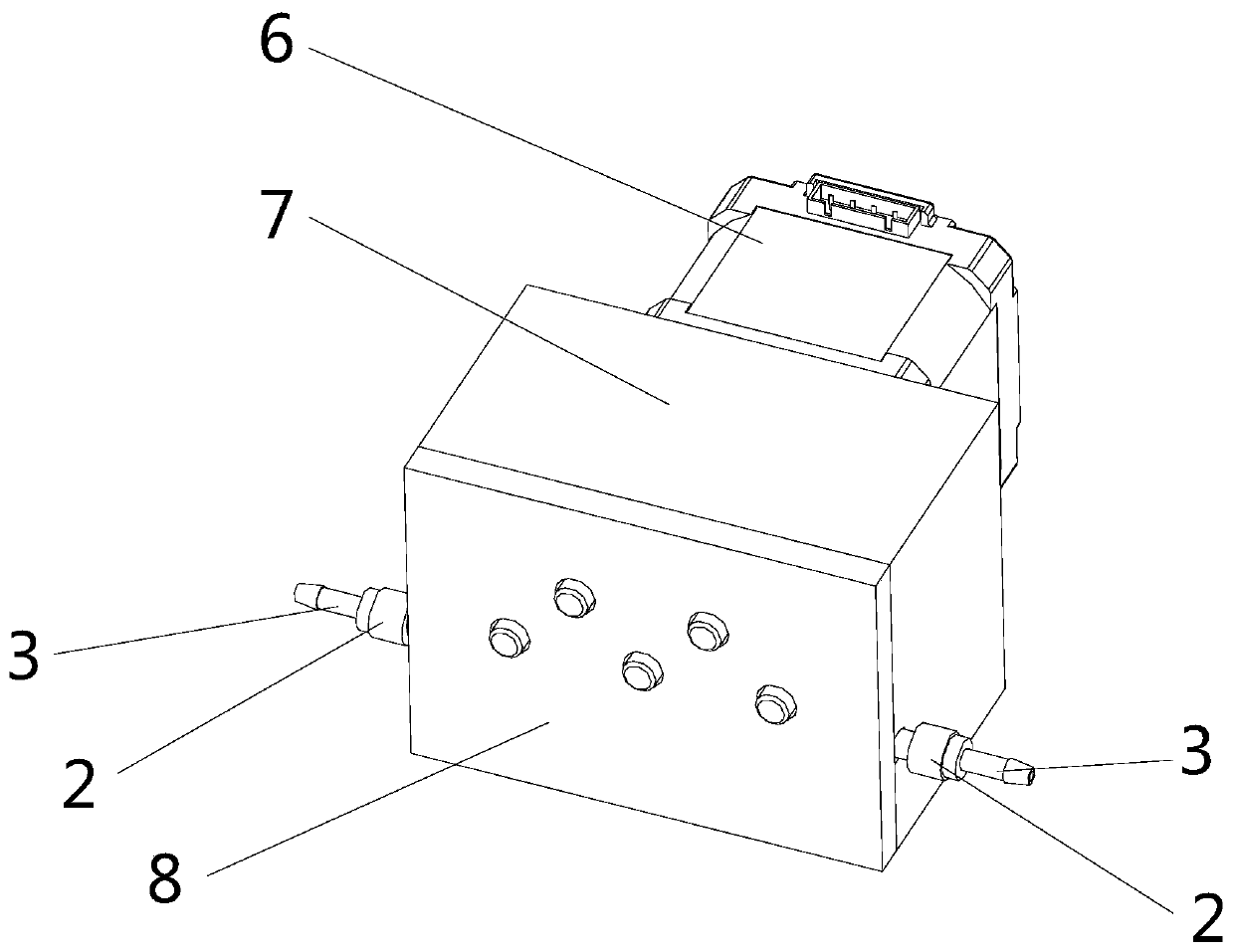

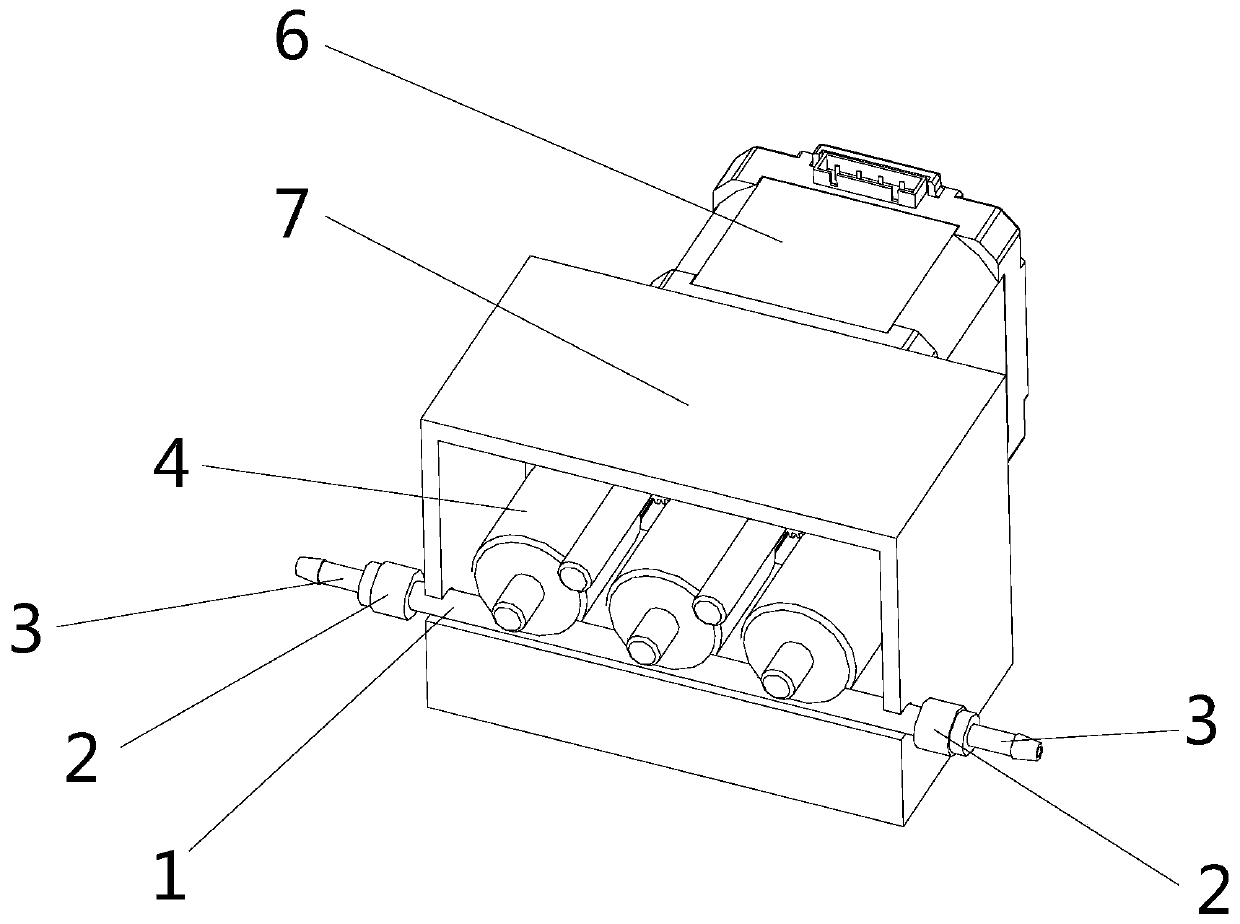

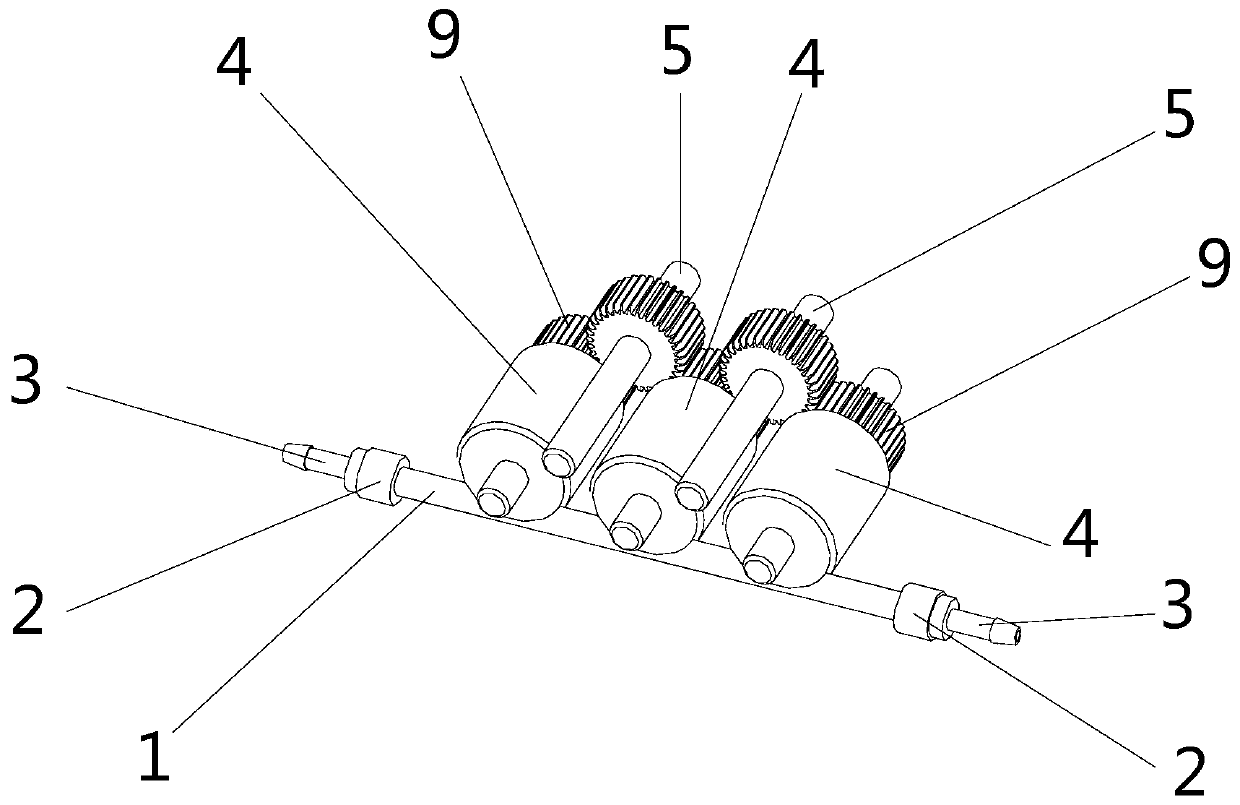

[0022] Such as Figure 1-3 The shown planar conveying type smog machine oil pump includes oil delivery pipe 1 and a flow rate adjustment mechanism. The flow rate adjustment mechanism is connected to the oil delivery pipe 1. The oil delivery pipe 1 is used to transport smoke oil. The flow rate adjustment mechanism can squeeze the oil delivery pipe 1. The pressure will be deformed to squeeze the internal air to generate a partial vacuum. When the flow rate adjustment mechanism rotates, the smoke oil can be input from one end of the oil delivery pipe 1 and output from the other end of the oil delivery pipe 1; and then by adjusting the flow rate adjustment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com