Preparation method of silane coupling agent modification montmorillonite functionality nanometer fat liquoring complex agent

A silane coupling agent, nanocomposite technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

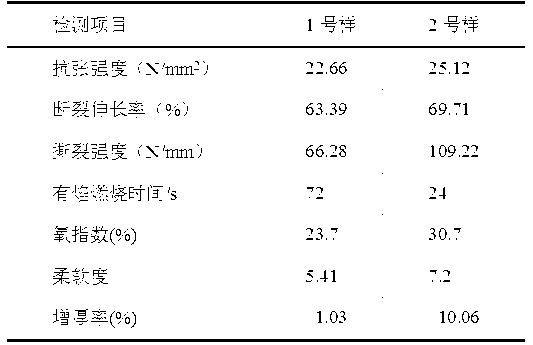

Examples

Embodiment 1

[0022] Step 1: Take 85 parts by weight of methanol and 5 parts by weight of deionized water into a three-necked flask, add 2.0 parts by weight of silane coupling agent, adjust the temperature control device until the temperature reaches 55 ° C, adjust the pH to 4.0 with glacial acetic acid, React at a constant temperature for 90 minutes; adjust the temperature control device until the temperature reaches 85°C, add 5 parts by weight of sodium montmorillonite, react at a constant temperature for 120 minutes, wash the product with 10 parts by weight of methanol and centrifuge for 10 minutes, repeat three times, and The final product was dried in an oven at 85°C for 24 hours to obtain montmorillonite modified by silane coupling agent;

[0023] Wherein, the silane coupling agent is selected from γ-aminopropyltriethoxysilane.

[0024] Step 2: Take 0.85 parts by weight of silane coupling agent modified montmorillonite and 40 parts by weight of rapeseed oil into a three-necked flask, ...

Embodiment 2

[0027] Step 1: Take 90 parts by weight of methanol and 10 parts by weight of deionized water into a three-necked flask, add 2.2 parts by weight of silane coupling agent, adjust the temperature control device until the temperature reaches 57 ° C, adjust the pH to 5.0 with glacial acetic acid, Constant temperature reaction for 105 minutes; adjust the temperature control device until the temperature reaches 87 ° C, add 5 parts by weight of sodium montmorillonite, and react at a constant temperature for 135 minutes, wash the product with 12 parts by weight of methanol and then centrifuge for 12 minutes, repeat three times, the The final product was dried in an oven at 90°C for 24 hours to obtain montmorillonite modified with silane coupling agent;

[0028] Wherein, the silane coupling agent is selected from γ-methacryloxypropyltrimethoxysilane.

[0029] Step 2: Take 3.86 parts by weight of silane coupling agent modified montmorillonite and 45 parts by weight of rapeseed oil into a...

Embodiment 3

[0032] Step 1: Take 95 parts by weight of methanol and 15 parts by weight of deionized water into a three-necked flask, add 2.4 parts by weight of silane coupling agent, adjust the temperature control device until the temperature reaches 60 ° C, adjust the pH to 5.5 with glacial acetic acid, React at a constant temperature for 120 minutes; adjust the temperature control device until the temperature reaches 90°C, add 5 parts by weight of sodium montmorillonite, react at a constant temperature for 150 minutes, wash the product with 15 parts by weight of methanol and centrifuge for 15 minutes, repeat three times, and The final product was dried in an oven at 95°C for 24 hours to obtain montmorillonite modified with silane coupling agent;

[0033] Among them, the silane coupling agent is selected from 3-aminopropyltrimethoxysilane.

[0034] Step 2: Take 6.87 parts by weight of silane coupling agent modified montmorillonite and 50 parts by weight of rapeseed oil into a three-necked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com