Method for preparing paper-making reconstituted tobacco substrate with high air permeability and high absorptivity

A high-absorbency, reconstituted tobacco leaf technology, applied in the preparation of tobacco, tobacco, application, etc., can solve the problems of low air permeability and absorbency, achieve the effect of improving softness and bulk, improving combustion quality, and the method is simple and feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

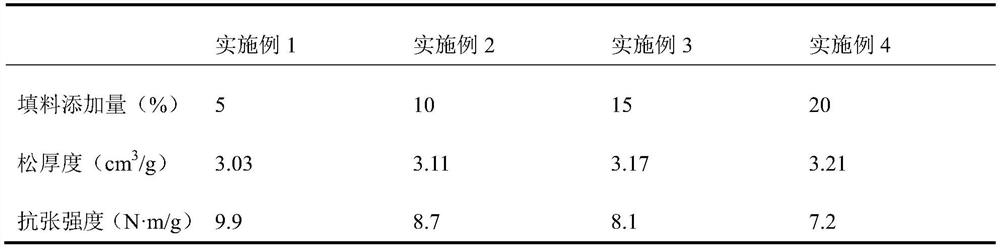

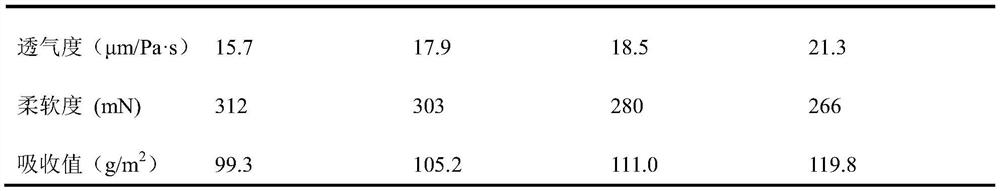

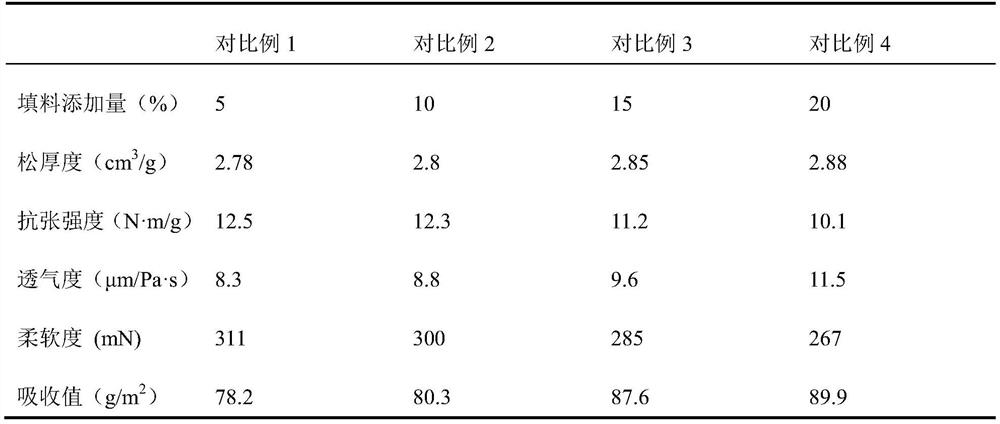

Examples

Embodiment 1

[0038] (1) Tobacco stem raw materials are extracted by dipping and one-stage refining to obtain tobacco stem pulp, and the beating degree is 12°SR. After the first-stage refined tobacco stem raw materials and tobacco leaves are mixed according to the ratio of 6:4, the second-stage grinding is carried out. After refining, the beating degree of the mixed slurry of tobacco stems and tobacco leaves is 18°SR.

[0039](2) The Russian "Wuzhen" brand bleached coniferous wood pulp was used as the added plant fiber, which was disintegrated by a pulper, and the added plant fiber slurry was obtained after being dispersed by the disintegrator, and the beating degree of the pulp was 12°SR.

[0040] (3) Use fluffy additives prepared from agricultural waste, with an average particle size of 10 μm, a sedimentation volume of 3.0ml / g, and a specific surface area of 200m 2 / g, the fluffy auxiliary agent is formulated to a concentration of 10% in mass concentration.

[0041] (4) The guar gum is...

Embodiment 2

[0044] (1) The tobacco stem raw material is extracted by dipping and one-stage refining to obtain the tobacco stem slurry, and the degree of beating is 14°SR. After the first-stage refined tobacco stem raw material and tobacco leaves are mixed according to the ratio of 6:4, the second-stage grinding is carried out. After refining, the beating degree of the mixed slurry of tobacco stems and tobacco leaves is 19°SR.

[0045] (2) The Canadian "Prince George" brand bleached hardwood pulp was used as the added plant fiber, which was disintegrated by a pulper, and the added plant fiber pulp was obtained after being dispersed by the deflaker, and the beating degree of the pulp was 14°SR.

[0046] (3) Using fluffy additives prepared from agricultural waste, the average particle size is 18 μm, the sedimentation volume is 4.5ml / g, and the specific surface area is 132m 2 / g, the fluffy auxiliary agent is formulated to a concentration of 10% in mass concentration.

[0047] (4) Chitosan i...

Embodiment 3

[0050] (1) Tobacco stem raw material is extracted by dipping and one-stage refining to obtain tobacco stem slurry, and the beating degree is 13°SR. After the first-stage refined tobacco stem raw material and tobacco leaves are mixed according to the ratio of 6:4, the second-stage grinding is carried out. After refining, the beating degree of the mixed slurry of tobacco stems and tobacco leaves is 20°SR.

[0051] (2) The Chilean "Star" brand bleached broad-leaved wood pulp was used as the added plant fiber, which was disintegrated by a pulper, and the added plant fiber pulp was obtained after being dispersed by the deflaker, and the beating degree of the pulp was 13°SR.

[0052] (3) Using fluffy additives prepared from agricultural waste, the average particle size is 25 μm, the sedimentation volume is 4.1ml / g, and the specific surface area is 116m 2 / g, the fluffy auxiliary agent is formulated to a concentration of 10% in mass concentration.

[0053] (4) Sodium carboxymethyl c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com