Environment-friendly styrene-acrylic emulsion paint and preparation method thereof

A styrene-acrylic emulsion, an environmentally friendly technology, applied in the field of coatings, can solve the problems of poor adhesion, poor water resistance, and poor leveling of the coating film, and achieve good weather resistance, excellent stain resistance, and improved workability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

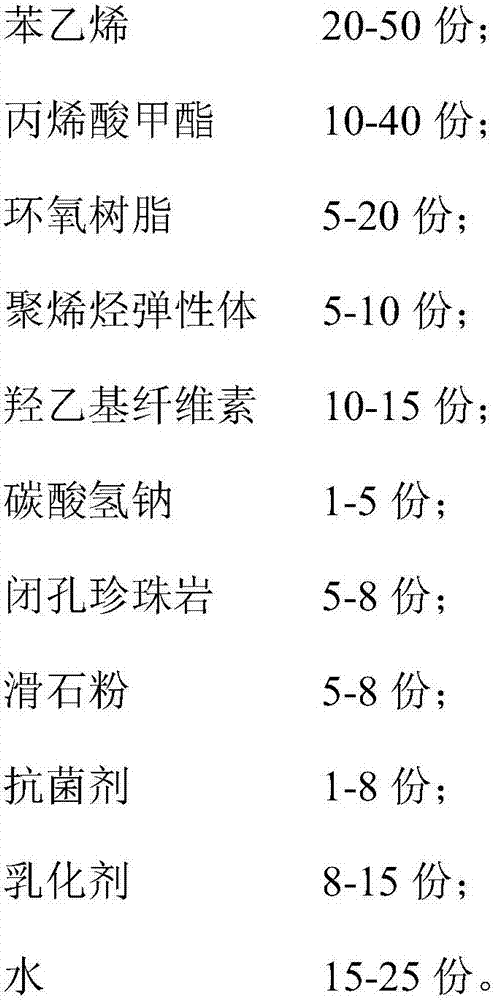

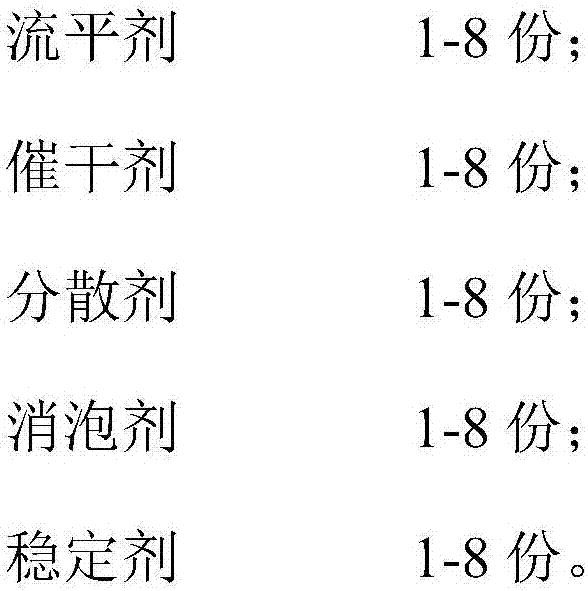

Method used

Image

Examples

preparation example Construction

[0038] A preparation method for environment-friendly styrene-acrylic emulsion paint, comprising the following steps:

[0039] 1) Add the amount of styrene, methyl acrylate, epoxy resin and emulsifier into the container, and stir for 30-50min at a stirring speed of 600-1000r / min to obtain a mixed emulsion;

[0040] 2) Under the condition that the stirring speed is 350-700r / min, add the polyolefin elastomer, hydroxyethyl cellulose, sodium bicarbonate and antibacterial agent in the formula amount into the mixed emulsion, after adding, adjust the speed to 100-150r / min, and keep it for 10-30min to get semi-finished products;

[0041] 3) Add closed-cell perlite, talcum powder, leveling agent, drier, dispersant, defoamer, stabilizer and water into the semi-finished product, stir evenly, and obtain the environmentally friendly styrene-acrylic acid Emulsion paint.

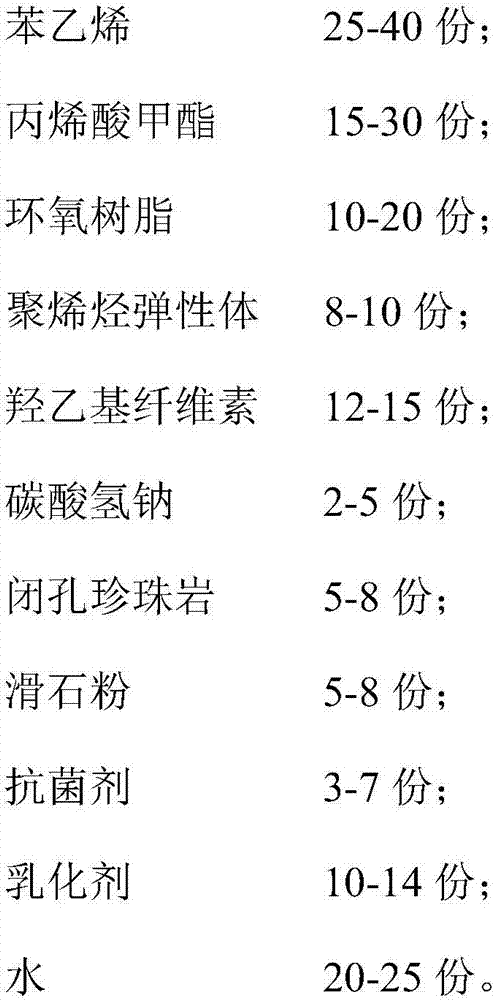

Embodiment 1

[0043] An environment-friendly styrene-acrylic emulsion coating is prepared from the following components in parts by weight (see Table 1 for details). Its preparation process is as follows in order: 1) add the styrene, methyl acrylate, epoxy resin and emulsifier of formula quantity in the container, under the condition that stirring speed is 600r / min, stir 50min, obtain mixed emulsion; 2) in Under the condition that the stirring speed is 700r / min, the polyolefin elastomer, hydroxyethyl cellulose, sodium bicarbonate and antibacterial agent of the formula are added in the mixed emulsion. After the addition is completed, the speed is adjusted to 150r / min, and Keep it for 30 minutes to obtain a semi-finished product; 3) Add closed-cell perlite, talcum powder, leveling agent, drier, dispersant, defoamer, stabilizer and water into the semi-finished product, stir for 15 minutes, and obtain The environment-friendly styrene-acrylic emulsion paint.

Embodiment 2

[0045] An environment-friendly styrene-acrylic emulsion coating is prepared from the following components in parts by weight (see Table 1 for details). Its preparation process is as follows in order: 1) add the styrene, methyl acrylate, epoxy resin and emulsifier of formula quantity in the container, under the condition that stirring speed is 600r / min, stir 50min, obtain mixed emulsion; 2) in Under the condition that the stirring speed is 700r / min, the polyolefin elastomer, hydroxyethyl cellulose, sodium bicarbonate and antibacterial agent of the formula are added in the mixed emulsion. After the addition is completed, the speed is adjusted to 150r / min, and Keep it for 30 minutes to obtain a semi-finished product; 3) Add closed-cell perlite, talcum powder, leveling agent, drier, dispersant, defoamer, stabilizer and water into the semi-finished product, stir for 15 minutes, and obtain The environment-friendly styrene-acrylic emulsion paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com